Articles

Computer Vision System Automates Characterization of Metal Powder

A computer vision system that has learned to classify metal powders could speed material qualification and advance machine learning in additive manufacturing.

Read MoreVideo: 3D Printing at Local Motors

3D printing plays multiple roles at the company’s Knoxville microfactory, from prototyping to the production of parts for autonomous vehicles.

WatchGE and Concept Laser Aim to Lead Digital Transformation of Industrial Production

European correspondent Barbara Schulz spoke to Concept Laser founder Frank Herzog to find out how the dynamic between the German company and U.S.-based GE forms the perfect symbiosis to grow a global AM business.

Read More3D-Printed Sneakers Gaining Traction

Under Armour, Adidas, Nike and New Balance are applying different additive manufacturing technologies and materials for customized kicks.

Read MoreIn Additive’s Evolution, Aerospace Proves the Fittest

As additive manufacturing shifts from prototypes to production, one industrial sector is ahead of the curve.

Read MoreBenefits of Additive Manufacturing in Functional Prototyping

Additive manufacturing enables companies to build functional prototypes faster, allowing for more iterations and better designs.

Read MoreTop 10 Stories of 2017

Popular topics include advances in metal 3D printing, medical applications and the auxiliary activities that support additive manufacturing.

Read MoreConformally Cooled Injection Mold Reduces Cooling Time by 55 Percent

With Renishaw’s help, Kärcher ended its production bottleneck using 3D-printed molds with conformal cooling channels.

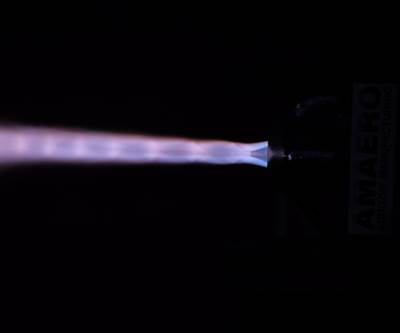

Read MoreAM Design May (Finally) Launch the Aerospike Engine

A team of engineers turns to additive design to create—and successfully test—“the holy grail of the spaceship movement.”

WatchOvercoming the Challenges of Copper

A research organization in Germany is developing a laser beam source that operates with a green light, enabling selective laser melting of a copper alloy.

Read MoreHere Is What a Four-Laser Machine Can Do—and Here Is the Hardware Used to Do It

One laser gets you this far. Two lasers get you this much farther. These productivity comparisons with a four-laser machine also show the cooling geometry that brings four lasers together.

Read MoreAdvantages of Wire Over Powder in Additive Manufacturing

Gefertec says its wire-fed additive manufacturing systems can overcome existing process limitations of powder-fed systems.

Read More