Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

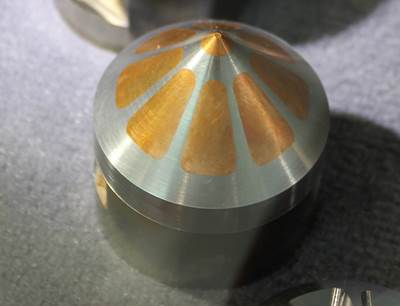

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

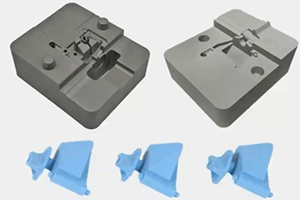

Machine tool builder Hermle is known for its high-precision milling systems, but the company also offers part production services using a hybrid platform that builds on this expertise. A subsidiary based in Germany is focused on operating the Metal Powder Application (MPA) process, a hybrid manufacturing strategy that combines five-axis milling with cold spray deposition. The process supports the precise addition of material, such as conformal copper areas added to injection mold tooling to improve cycle times. MPA also enables the creation of complex internal geometries, functionally graded materials, and, because of the cold spray process, even the inclusion of other components such as sensors. This video filmed at IMTS 2024 describes the process and showcases several representative case studies (despite operating the MPA process for nearly a decade, this event represents the first time Hermle has showcased it at IMTS – The International Manufacturing Technology Show).

Related Resources

- More on the MPA process

- Another cold spray application for embedded electronics

- More on the advance of hybrid machine tools

Transcript

Most hybrid machine tools use a welding like process to apply metal material in sequence with machining. But what if you could strategically apply functional materials without melting?

I'm Stephanie Hendrixson with Additive Manufacturing Media here at IMTS 2024 in the Hermle booth. Hermle is known for its high precision machining centers, but it also has a subsidiary focusing on providing hybrid manufacturing services through 3D printing and five axis milling on the same machine. The additive process is called MPA or Metal Powder Application.

Hermle provides MPA services using four machines that it designed and created itself, located in Germany. This is actually the first time that this technology has been displayed at IMTS in North America.

So MPA works by using compressed air to fire particles of material at an existing substrate or part. The powder is accelerated to very high speeds and fired at a pre-heated workpiece. The particles deform and bond to the substrate as well as each other, so you end up with high density, low porosity metal that can be machined almost right away.

Initially, most applications for MPA had to do with conformal cooling, introducing copper into mold tooling for heat dissipation to improve cycle times. But now MPA can be applied with copper, as well as tool steel, stainless steel, Invar and many other materials. And the customer doesn't have to choose just one. You can actually do functional graded materials by changing the mix of powder that is being applied to the part. MPA can even be applied to produce ceramic matrix composites, where they can add up to 30% ceramic powder into the mix.

Hermle also uses a support material for parts with complicated internal cavities or other structures. This satellite waveguide, for instance, has this complicated internal geometry. During manufacturing, these cavities would have been filled with that material, which was then washed out later.

And because there's no melting involved, MPA opens up the opportunity to incorporate sensors, thermocouples, other components into your hybrid manufactured parts. For instance, this semiconductor frame is made of Invar with these copper tubes. Hermle machined channels, placed the copper tubes and then printed Invar over top to fully enclose them and produce this finished assembly.

Using this process, material can be applied in five axes and can be used very minimally just to add functionality to the specific places where you need it.

If you'd like to learn more about MPA or other types of hybrid manufacturing

technologies, you can find a link to our collection of stories in the show description. You can also follow Additive Manufacturing Media

wherever you're watching and sign up for our newsletter, The BuildUp, to stay up to date on new technologies and applications.

Related Content

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreGRM Develops Software for OverHiPP Project to Improve Accuracy of Digital Twins

As part of an OverHiPP study, GRM has created software that enables users to virtually model and analyze 3D printed structures at a level of detail never seen before — an accurate digital twin can now be generated, enabling precise design decisions to be made.

Read MoreJuggerBot 3D Chooses Research Partners for Air Force Large-Format Hybrid Additive Manufacturing Project

Oak Ridge National Laboratory and Mississippi State University’s Advanced Composite Institute have been selected to assist in the research and technical development of production workflows using thermoplastic and thermoset deposition.

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreRead Next

This Rocket Fuel Injector Is a Solid Part That Contains a Working Motor: The Cool Parts Show #1

Our new video series debuts with a look at a solid metal part made through additive manufacturing that was built with a motor embedded inside. The motor sealed within the part adjusts the rocket’s fuel mixture while the rocket is in flight.

Read MoreThe Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read MoreHermle Combines Metal Powder Application Process with Five-Axis Machining

Hermle integrated its MPA technology, a process where metal powder is applied by kinetic compacting to build completely sealed materials, in a Hermle five-axis machining center to create parts with highly complex inner geometries.

Read More

.jpg;width=70;height=70;mode=crop)