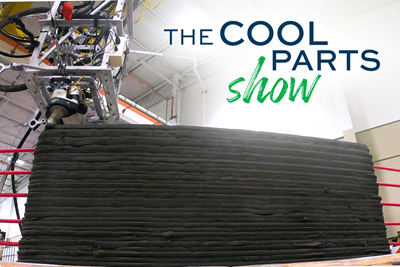

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Alquist 3D, based in Greeley, Colorado, has developed technology for 3D printing buildings, homes and infrastructure. Working with partners, the company has created a robot-based 3D printing system that can be transported to job sites and operated within a compact footprint for new constructions and expansions. Key to this 3D printer, though, is the material it uses; rather than cementitious concrete, Alquist 3D’s machine prints with carbon-neutral geopolymer. The blend requires precise control both in mixing and extrusion, but offers good density, water tightness and a fast curing rate that enables structures to be 3D printed often faster than they could be poured or otherwise constructed with traditional methods.

In addition to licensing its technology to support 3D printing of full homes and buildings, Alquist 3D is also setting up a products division at its Greeley headquarters that will manufacture infrastructure items such as water-conveying curbs, planters and benches like the one I tried out during filming.

Related Resources

- More applications for 3D printing in the construction industry

- Read more about Alquist 3D and its goal to reach carbon-negative construction in this article

- Learn more about the environmental impact of concrete and why reducing its use is advantageous

- Another example of new technology for 3D printing buildings

Transcript

00:00:00:04 - 00:00:23:29

What if our houses, buildings and infrastructure could be made faster, more affordably and from carbon neutral, or maybe even carbon negative materials? Alquist3D is working on all of these problems. I'm Stephanie Hendrickson from Additive Manufacturing Media. I'm here in Greeley, Colorado at the headquarters of Alquist3D. They are addressing problems around construction using 3D printing technology.

00:00:24:06 - 00:00:46:19

There are three pillars of this business. First, they are developing technology to 3D print structures in the field, including a carbon neutral material, blending equipment and recipes, and a mobile robot based printer that will be able to print homes and other buildings on site. Second, they are building out manufacturing capacity to produce infrastructure items such as planters, curbs and benches like this one.

00:00:46:26 - 00:01:13:01

There are a couple of ways that they do this. They print things directly like this. You can see the layer lines of how this bench was constructed, but they are also using a polymer 3D printer to produce molds, which can then be filled using robot technology and the material that they've developed. And then finally, they are licensing. They’re licensing their technology to other organizations that want to be able to 3D print onsite or produce these types of structures.

00:01:13:04 - 00:01:37:26

They are also working on a curriculum that they have developed with the Aims Community College, that will be licensed to other universities that want to teach the skills necessary to do this work. Applying 3D printing to construction has a number of benefits. For Alquist, they are able to produce structures more affordably. One of the organizations that they work with is Habitat for humanity, and they have a project underway soon to build a number of different homes here in Colorado.

00:01:37:29 - 00:02:03:01

It also allows for more innovative designs. They are working on iterating through different curb structures that would allow for better water drainage. That will be a product that they produce here in this factory. The material that they're printing with is called a geo polymer specially devised for this use case. It's a combination of alumina silica, fly ash and some other additives to produce a dense, non-porous, high compressive strength material.

00:02:03:05 - 00:02:30:10

The geopolymer they're printing with today is carbon neutral, but it could one day be formulated to be carbon negative so that buildings and benches and houses could be sequestering carbon in the atmosphere instead of adding to it. There are some tricks to 3D printing with geo polymer. The material is highly sensitive to humidity, to temperature and so Alquist is doing a lot of research right now just to dial in exactly the right print parameters for the conditions where this material and this technology is going to be used.

00:02:30:12 - 00:02:57:00

They're developing all of this knowledge so that the actual printing parameters, the conditions, the material mixing can all be automated in the future. So it's still fairly early for this company, but they have a number of different construction projects that will be in work later this year. They're working with a number of different schools and other licenses, and they have a number of planters curves and other infrastructure elements that they will be printing right here in Greeley very soon.

00:02:57:03 - 00:03:14:07

If you'd like to learn more about how additive manufacturing is being applied in construction, see our playlist and the other links in the video description below. And if you're interested in more about additive manufacturing, materials, technology and applications, subscribe to Additive Manufacturing Media. We'll put a link in the show description. Thanks for watching.

Related Content

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

3D Printed Prefab Homes, Made from Composite and UL-Certified

Mighty Buildings wants to change the construction industry with prefabricated houses 3D printed on demand from thermoset polymer composite. Two such buildings have already been installed.

Read More3D Printed Concrete Is Key to This Smart Wall: The Cool Parts Show #40

The SkyBAAM cable-driven 3D printer creates opportunities for embedded functionality in concrete, as demonstrated in this episode of The Cool Parts Show.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)