US Navy Successfully Utilizes Additec’s Liquid Metal Jetting Technology While Afloat

The U.S. Navy successfully used a Liquid Metal Jetting (LMJ) 3D printer aboard one of its vessels, enabling them to print high-strength aluminum alloy parts on-demand while in port. This innovation can change how critical parts are manufactured in remote or challenging environments to potentially reshape naval operations.

Aluminum 6061 parts printed with the ElemX on the USS San Diego. Source: AddiTecAluminum 6061 parts printed with the ElemX on the USS San Diego. Source: AddiTec

In an advancement for additive manufacturing (AM) in maritime operations, the U.S. Navy has successfully utilized the ElemX 3D printer, which is based on AddiTec’s Liquid Metal Jetting (LMJ) technology to produce functional parts afloat. The company says this use of LMJ technology marks a significant milestone in the field of LMJ, which is specifically tailored for high-strength aluminum alloys such as Al-6061.

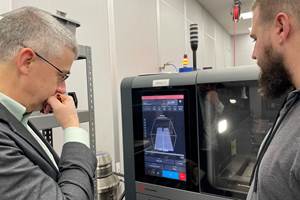

Recently, Navy sailors printed essential parts using the containerized ElemX 3D printer on the USS San Diego, while it was home ported in San Diego. The process proved to be efficient and straightforward, even in the demanding conditions of an active maritime environment. The printed parts were evaluated for quality and performance, with results indicating the components were both acceptable and fully functional for their intended applications.

Containerized ElemX. Source: AddiTec

“We are thrilled with the performance of the ElemX 3D printer,” says Dr. Garth Hobson, director of the Consortium for Advanced Manufacturing, Research and Education, at the Naval Postgraduate School, Monterey, California. “The ease of use and the quality of the printed parts exceeded our expectations. This technology represents a significant enhancement in our ability to maintain and repair equipment while at sea.”

The Naval Postgraduate School (NPS) and the Consortium for Advanced Manufacturing, Research and Education (CAMRE) are playing a pivotal role in advancing the use of 3D printing technologies, particularly the ElemX 3D printer. This collaboration focuses on testing and researching innovative use cases that demonstrate the operational benefits of AM in naval environments. By leveraging the capabilities of the ElemX 3D printer, NPS and CAMRE have successfully developed and evaluated components and systems that can be produced on demand at sea, directly addressing logistical challenges. This was highlighted by the deployment of the ElemX 3D printer on the USS San Diego, where it was used to fabricate critical parts, reducing downtime and enabling faster repairs, ultimately enhancing the ship’s operational readiness and efficiency. The research also explores the broader implications of 3D printing in enhancing the Navy's adaptability and supply chain resilience in remote or combat settings.

AddiTec says it dedicated considerable efforts toward refining the ElemX 3D printer’s capabilities to meet the stringent requirements of naval operations. The company worked to develop a robust, user-friendly solution which has been successfully tested, as evidenced by the implementation and positive feedback from U.S. Navy sailors.

“We have worked tirelessly to ensure that our 3D printing technologies meets the specific needs of maritime operations, and we are working to continuously enhance their reliability and efficiency, ensuring they are fully mission-ready for any operational demands,” says Brian Mathews, AddiTec’s CEO. “Seeing our efforts come to fruition with the successful printing of functional parts at sea is incredibly rewarding. We remain dedicated to our ongoing collaboration with the Navy, focusing on advancing LMJ technology within our innovative new Hybrid Series, which seamlessly integrates both additive and subtractive manufacturing capabilities into a single machine.

The ability to print high-strength aluminum alloy parts on demand is said to represent a transformative shift in how the U.S. Navy can manage its resources and address maintenance challenges. This advancement not only improves operational readiness but also reduces dependency on traditional supply chains to mitigate contested logistics scenarios providing a strategic advantage for expeditionary and distributed maritime forces.

Related Content

Video: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreThe Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More