CEAD Flexcube’s Integrated Milling Options Fully Automate LFAM Postprocessing Within Single System

Formnext 2024: The system comes in a space-efficient, cube-shaped 3D printer for LFAM printing with integrated milling options and a 3 + 1 axis system for 45-degree printing.

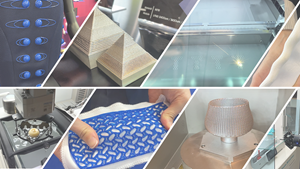

CEAD launches turnkey Cartesian-style LFAM platform based on its high-throughput pellet extrusion technology. Source (all images): CEAD

CEAD’s Flexcube 3D printing platform offers an accessible, high-performance, high-throughput solution for large-format additive manufacturing (LFAM) based on the company’s pellet extrusion technology.

This single, space-efficient cube-shaped 3D printer for printing large industrial parts features integrated milling options and a 3 + 1 axis system for 45-degree printing. It is designed to facilitate manufacturing a wide range of applications and enables full-part completion — handling 3D printing and postprocessing of complex designs in one automated workflow.

“With the Flexcube, we’re redefining possibilities for industry innovators to manufacture within an accessible LFAM system,” says Lucas Janssen, CEAD CEO. Designed to simplify and enhance production, the Flexcube offers an all-in-one LFAM platform that minimizes entry barriers, such as space requirements and robot knowledge, making the technology accessible for a wide range of users.

The company says the Flexcube resulted from more than 10 years of market insights and customer feedback, catering to the rising demand for accessible LFAM technology designed for industrial manufacturing. “We identified a market gap where companies want to adopt large-format 3D printing with a straight forward approach, and the Flexcube fills that,” Janssen says. “Its user-friendly and intuitive design is ideal for users that want to focus on the end result: manufacturing large-format composite parts at cost-effective production rates.”

The Flexcube Architecture and Design is well suited for serial production of interior pieces and decorative elements.

With integrated milling options, the Flexcube is an all-one-one platform that enables manufacturers to fully automate the production of finished parts within a single system. Its compact dimensions make it well suited for spaces such as universities and design studios, requiring just 2.5 meters in ceiling height. The machine ships in a single container, completely assembled, enabling customers to start production without extensive on-site assembly time.

“By removing unnecessary delays, we help customers implement their projects as quickly as possible,” Janssen says. “With the Flexcube, users will rapidly experience the transformative benefits of this technology,” he added.

Overall, the Flexcube platform empowers users to smoothly transition to an all-in-one LFAM platform, simplifying the complexities that some might associate with large-format 3D printing.

Flexcube Solutions for Specific Sectors

The Flexcube is designed as a modular series tailored to specific industries. The Flexcube Architecture and Design model, launched at Formnext 2024, is well suited for serial production of complex designs like furniture and interior elements, such as decorative panels. It optimizes production by enabling high printing speeds, the ability of printing multiple parts on a single print bed and reducing space requirements — all while minimizing material use, promoting circularity and maximizing return of investment.

“This technology helps manufacturers to move towards a more sustainable production method in more ways than one,” Janssen says. Other Flexcube configurations tailored for specific markets will also be available.

“The Flexcube is designed to maximize print volume with exceptional space efficiency, as reflected in its impressive build volume-to-cell ratio,” says Maarten Logtenberg, CEAD CTO. “For users requiring an even larger print area, its modular design allows for an additional expansion up to 12 meters.”

The machine is designed for continuous operation purposes and its 45-degree rotating extruder extends creative potential by supporting complex geometries beyond traditional 3-axis 3D printing.

“Equipped with the Siemens Sinumerik ONE CNC controller, the Flexcube delivers precise, high-quality prints essential not only for sectors like architecture and design which require excellent surface finishes but also for industries that prioritize accuracy, precision and the overall integrity of the final printed part,” Logtenberg says. “With the Flexcube, we’re offering an exceptional Cartesian all-in-one LFAM platform optimized for 3D printing — setting it apart from traditional platforms designed for milling.”

Related Content

Finland’s Largest Metal 3D Print Withstands Pressure Vessel Test, Vastly Exceeding Expectations

The pressure vessel was created in cooperation between Andritz Savonlinna Works and the Finish Additive Manufacturing Ecosystem (FAME), and withstood the nondestructive and destructive tests carried out by LUT University.

Read More7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

Read MoreLithoz CeraFab System S320 LCM Printer Designed for Efficient, High-Capacity Industrial Serial Production

Formnext 2024: The system offers a build speed of up to 150 layers per hour and layer thickness of 20–200 µm.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More