3D Printing Materials

In machining, a part’s form may change in the process, but its material properties end as they started. In additive, the 3D printing process determines the part's shape as well as its material properties. Variables like processing temperatures, nozzle diameter or laser spot size, gas flow, and more can affect layer adhesion, porosity and density of the final material. The main classes of materials used in 3D printing today are polymers, metals, composites, ceramics and sand

ESSENTIAL READING

VIEW ALLUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

WatchThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

Listen10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

WatchWhat is Powder Bed Fusion 3D Printing?

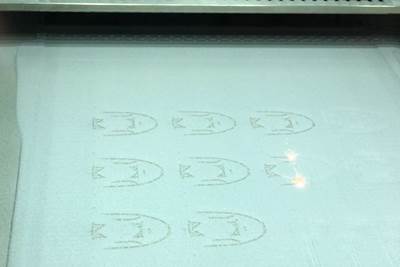

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

WatchAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

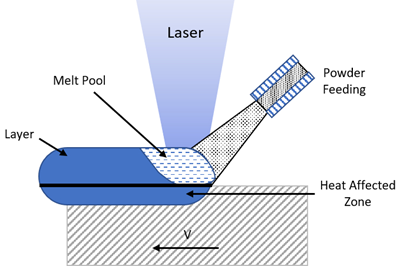

Read MorePowder Comparison: Standards for DED Material Substitutes

What powder properties lead to performance similar to a DED powder? Basic flowability energy, particle density and particle morphology are key candidates.

Read MoreLatest Materials News And Updates

MatGPT Enterprise Uses AI to Integrate and Leverage Internal Data Into a Dedicated, Secure Knowledge Database

Formnext 2024: Fehrmann MaterialsX’s AI solution has been specifically designed to help companies optimize workflows, increase efficiency and improve customer communication.

Read MoreNano Dimension Develops Advanced Software, Resin and Printers for Micro 3D Printing

Formnext 2024: The Fabrico 3.2 software for Fabrica micro 3D printers is said to deliver improved print times of up to 70%, while the Ataru resin is engineered specifically for digital light processing 3D printers. Also, the Admatec series of 3D printers have the capability to 3D print advanced, complex technical ceramics.

Read MoreSandvik Osprey HWTS 50 Hot Work Tool Steel Developed for Enhanced Printability

The material offers improved tempering and thermal fatigue resistance as well as thermal conductivity compared to conventional H-class hot work tool steels.

Read MoreAIM3D Validates Voxelfill Strategy for Overcoming Inhomogeneous Strengths in 3D Components

The strength-enhancing effect of Voxelfill has now been demonstrated for fiber-filled plastics with the tensile strengths of 3D components coming close to those produced through classic injection molding.

Read MoreFormlabs Expands SLA/SLS Ecosystem With New Materials, Postprocessing Tools

The new hardware, software and materials are designed to streamline postprocessing and unlock new workflows.

Read MoreSupernova Creates Defense and Space Business Unit to Develop 3D Printing of Military-Grade Energetic Materials

Target applications for the new business unit include solid rocket motors which are critical components for the next-generation hypersonic platforms.

Read MoreFeatured Posts

3D Printing With Recycled Powders: Reducing Waste and Material Costs

Can you print high-quality parts using recycled thermoplastic powder? JawsTec saves 2 tons of waste per year by investing in SLS printers that reuse scrap to make new parts.

Read MoreCranial Implant 3D Printed From Hydroxyapatite Ceramic: The Cool Parts Show #76

Cranial implants are typically made from titanium or PEEK; in this episode of The Cool Parts Show, we look at how implants made from a bioceramic can improve osseointegration and healing.

Watch3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreFeatured Media

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

WatchVideo: Orbit X Pro Football Helmet Uses 3D Printed Lattices

The lightweight helmet from Xenith will be used by NFL and collegiate football players beginning in fall 2024.

WatchVideo: A Mechanical Method for Metal Powder Production

Metal Powder Works has developed a method for producing powders from solid barstock, no melting required. This video covers how the process works and benefits of mechanical production of powders.

WatchFAQ: Materials

Can metal be 3D printed?

Yes. On the metals side, the most commonly 3D printed materials include aluminum, titanium, stainless steel, Inconel and cobalt chrome. Copper has historically been difficult to 3D print with laser-based systems, but innovations such as blue-light lasers make this possible; reflective metals like this may be easier to print using other methods such as binder jetting. An alloy suitable for one metal 3D printing method may not be appropriate for all such methods.

Can sand be 3D printed?

Yes, sand can be 3D printed through binder jetting to selectively adhere the grains together.

What is a thermoplastic?

A thermoplastic is a plastic polymer that can be heated to pliability, shaped either in a mold or through extrusion printing and then cooled back to a solid form. The makeup of a thermoplastic is such that the process of heating, shaping and cooling can be repeated without damage to the material.

What is a metal matrix composite (MMC)?

A metal matrix composite blends a metal alloy with another material such as ceramic.

The composite combines the light weight of aluminum with the strength, hardness and heat resistance of ceramic, making this material a promising choice not only for engines but also for applications in which high stiffness is needed for vibration control, or a low coefficient of thermal expansion is needed because of an extreme temperature range (the case with satellite parts). Yet the material’s very combination of heat resistance and hardness makes it difficult and costly to machine. Additive manufacturing addresses this problem because it is not just near-net-shape (true of a molding), but rather very near to net shape. Source: Metal Matrix Composite Demonstrates Additive Manufacturing’s Promise for New Materials