Articles

Printing End-Use Parts from High-Performance Ceramics

The lithography-based ceramic manufacturing (LCM) process allows the cost-effective production of ceramic parts even for a batch size of one.

Read MoreApplying Material Like Toner Promises AM at Speeds Like Injection Molding

The Stratasys-founded company Evolve debuts its STEP technology for production-scale additive processing.

Read MoreAccepting the AM Revolution at Baker Industries

Making a case for additive manufacturing integration whenever it makes sense is the standard at Baker Industries.

Read MoreEurope Seeks to Develop the Jack-Of-All-Trades of Additive Manufacturing

Supported by the European Union's Horizon 2020 Research and Innovation Program, the Kraken project team aims to develop an AM machine that can process large functional components ranging to 20 meters in length, made of plastics, metal or both.

Read MoreVideo: Is There a Personnel Challenge in Additive Manufacturing?

Adam Clark of Tangible Solutions sees the personnel advancing. The discipline of conventional manufacturing is coming to additive.

Watch3D-Printed Windform SP Part Helps Team Set New Speed Record

With no time left to make a NACA duct out of fiberglass using a mold and layup tooling, CRP USA 3D printed it from Windform SP to withstand the conditions of the Bonneville Salt Flats.

Read MoreAuburn University's Roadmap to Additive Manufacturing Education

As additive manufacturing workforce needs grow and AM technologies evolve, what does a higher-ed additive program look like? Is additive manufacturing a college major, minor or something else?

Read MoreHow to Accelerate Industrial Additive Manufacturing

The 2018 Additive World Conference was dedicated to industrial additive manufacturing and covered all relevant topics from the fields of 3D design, simulation, manufacturing and materials as well as case studies.

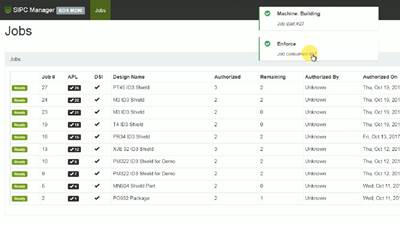

Read MoreWill Control Over Part Data Expand and Simplify AM Supply Chains?

Digital rights management for manufactured part files will enable OEMs to enforce manufacturing requirements at a distance, potentially providing an alternative to closely held relationships with suppliers of critical AM parts.

Read MorePrinting Solid, Simple Metal Parts in Minutes, Spee3D Process Is Competition for Casting

Kinetic energy additive process bonds metal not through melting, but with the use of compressed shop air.

Read MoreWith Additive Manufacturing, No Tooling Is Required

In conventional manufacturing methods, tooling can easily cost hundreds of thousands of dollars. With AM, you print as needed, no jigs, fixtures or tooling required.

Read MoreTracks and Trends in Additive Manufacturing

RAPID + TCT 2018 provides a cross-section of the additive manufacturing sector, with conference tracks for AM novices through experts.

Read More