Benefits of Additive Manufacturing in Functional Prototyping

Additive manufacturing enables companies to build functional prototypes faster, allowing for more iterations and better designs.

Previously, we saw how additive manufacturing (AM) can be used to more quickly and flexibly build parts that can be used as direct replacements for conventionally made components. This month, I want to discuss another “speed play” with AM: namely, functional prototyping.

For 30+ years, companies have used 3D printers to create prototypes and concept models that were primarily used for “fit and form” checks. As such, functionality was not critical, because we knew that plastic 3D-printed parts were not going to be as strong as the final injection-molded parts. Now that we can print metallic components, companies can additively manufacture functional prototypes, not just fit-and-form models. By doing so, they can save days, weeks and even months rather than wait for a machine shop to fabricate a functional prototype via more conventional methods. Additionally, companies can make more prototypes in a given time period, enabling more iterations, more customer feedback and so on, by taking advantage of AM’s quick turn-around time relative to many conventional approaches.

So AM enables speed and flexibility in functional prototyping, just as it did in direct part replacement.

Case in point is the piston crown example I have used in previous columns. In this project, the sponsoring company wanted to investigate the use of AM to directly produce functional prototypes that were taking too long (and costing too much) to make. The challenge, though, was that the piston crowns they were considering were not designed for AM; they were designed to be cast and machined, and the resulting geometry did not lend itself well to AM. The overhanging features required extensive support structures during additive fabrication, and these supports were not only difficult and challenging to remove, but also added significantly to material costs and build time—exactly what the company was trying to avoid.

Corey Dickman, Matt Woods and I got a chance to adapt the design for AM. While some of the features underneath the part are functional, many of them are not; they are artifacts of the manufacturing process and can be modified without affecting part functionality. The first modifications we made were to some of the overhanging features of the piston crown. this enabled us to reduce the volume of the supports by 55 percent (from 103.6 cm3 to 46.3 cm3) and therefore reduce the weight of the supports from 58 percent of the build to 22 percent of the build (see Figure 1).

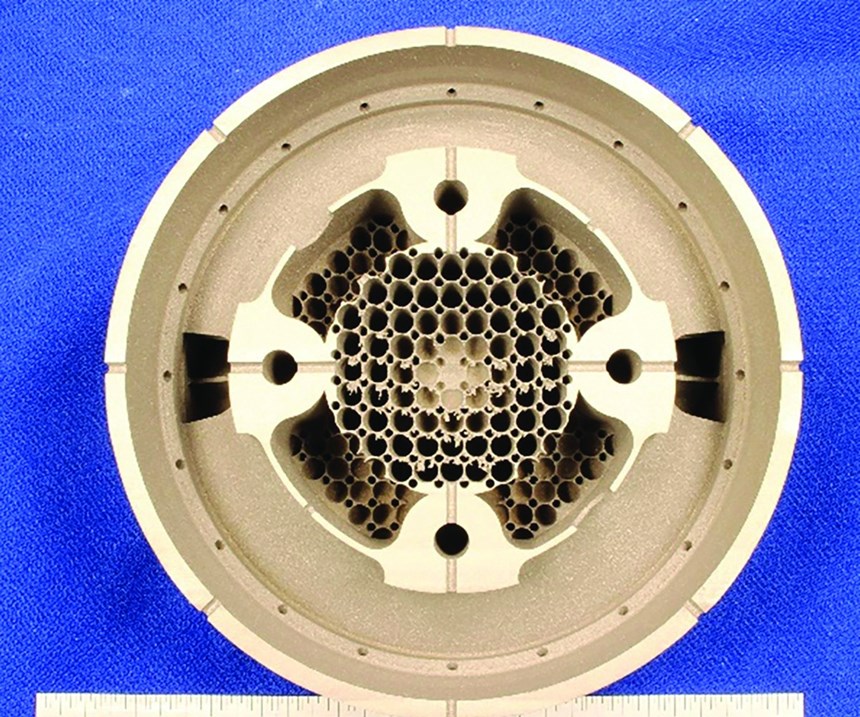

After additively manufacturing the original and reduced support piston crowns successfully, we got more aggressive with our enhancements to improve piston performance. We created conformal cooling channels under the combustion chamber to improve heat transfer, and we added oil drains and additional oil passageways to improve lubrication during operation. Finally, we added a lattice structure on the underside of the part to improve rigidity while adding only minimal extra weight. Corey also was able to leverage machining allowances to add material near the piston rings in such a way that they were self-supporting. All combined, the enhanced piston crown design required zero additional supports to enable additive manufacture in stainless steel (see Figure 2).

The final piston crown weighed 7.5 percent more than the original piston crown yet required 11 percent less time to manufacture. It had zero support structures to remove, and once it was machined to its final specifications, it was actually 4.1 percent lighter than the original design yet had 37 percent more surface area to improve heat transfer. In short, by designing for AM, we enabled a functional prototype that could be made in two to three days with minimal postprocessing effort, compared to two to three weeks via conventional methods.

So why should machine shops care about this? Those that subsist off making functional prototypes could find themselves displaced from the supply chain if their customers decide to leverage AM technology. It may be in their best interests to understand how to contribute to AM rather than be disrupted by it.

This article originally appeared in Additive Insights, a monthly column in Modern Machine Shop magazine.

Related Content

Foundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreFaster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read More3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

Read MoreTitanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More