Siemens’ Partnerships Work to Accelerate Scaling of Additive Manufacturing Technologies

Formnext 2024: Siemens is focusing on collaborations that emphasize the importance of innovation and open, interoperable technologies to facilitate the integration of additive manufacturing into conventional manufacturing technologies.

VLM Robotics has developed a fully automated autonomous mobile robot solution based on Sinumerik One, Sinumerik CNC Robotics and Simove. Source (all images): Siemens

Siemens is collaborating with a variety of additive manufacturing (AM) partners to help advance the integration of AM into conventional manufacturing technologies, accelerating the scaling of AM solutions and working to develop a circular economy. These collaborations include expanded AM offerings on its Xcelerator Marketplace; another company joining the Additive Manufacturing Industrialization Navigator (AM I Navigator) collaboration; and efforts to develop a circular economy.

New Offerings on Xcelerator Marketplace

Siemens has added LEAM Technologies’ large-format additive manufacturing (LFAM) with light-based welding technology to its Xcelerator Marketplace.

LEAM Technologies, a provider of large-format additive manufacturing (LFAM) with light-based welding technology, is working with CEAD to open up new possibilities in AM. By using light to heat the material, LEAM enables increased mechanical strength, even in difficult-to-print materials. LEAM’s temperature monitoring system enables real-time temperature control during the AM process. The edge-based solution, which is now available on the Siemens Xcelerator Marketplace, continuously checks and regulates the temperature at every position of the component to improve the quality of the printed parts. With this technology, manufacturers can make their production processes more efficient, improve product quality and reduce reject rates at the same time. It’s a technology well suited for the aerospace, defense and energy industries.

VLM Robotics has developed the Calypso model, which is a fully automated autonomous mobile robotic solution based on Sinumerik One, Sinumerik CNC Robotics and Simove as well as its own CNC robotic machines. It also offers the Gemini model which is designed for XXL hybrid AM. The company’s hybrid robotic solutions can perform printing (directed energy deposition, cold spray), welding, control and milling tasks. The company says its range of CNC robotic machines can be seamlessly integrated into the production environment, enabling agile repair and production work on large components. Also, digital threads play a integral role in this, as they are end-to-end digital twins of all data and information across the entire life cycle of a product, machine and process, enabling seamless integration and transparency from development to disposal. It is said the complexity of controlling a highly scalable multitechnology robotic machine while meeting high precision and quality requirements necessitates a high level of industry, automation and digitalization expertise. VLM Robotics’ offerings on the Xcelerator Marketplace include customized digital solutions that enable the seamless integration and tracking of all relevant data and information throughout the entire production life cycle. These turnkey solutions are well suited for the railway, shipbuilding, aerospace and energy industries.

Developing a Circular Economy

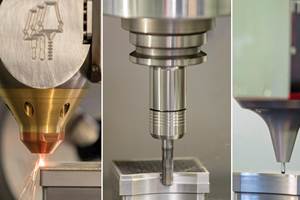

Siemens is also focused utilizing AM technology as an enabler of the circular economy with its Toolcraft technology, which enables creative production optimization by intelligently combining CNC machining, additive production techniques and know-how transfer. Designing products so they can be reused, recycled or safely returned to the environment at the end of their life cycle promotes a sustainable value chain, reduces waste and conserves resources. Product design plays a vital role in this as 80% percent of the environmental impact is determined in the design phase. Siemens relies on industrial AI and the industrial metaverse to generate optimized designs and enable automated, intelligent workflows. Siemens says its Toolcraft technology, for instance, can improve the design and engineering process for components by 30% for new designs and 85% for design modifications.

Haddy is building a global network of local microfactories equipped with hybrid Flexbot systems and recycling units that shorten the supply chain and help the environment by reducing waste.

Haddy’s technology is also focused on the circular economy for furniture manufacturing with its advanced 3D printing and robotics, producing high-quality, sustainable products at a low cost and on a commercial scale. The company is building a global network of local microfactories equipped with hybrid Flexbot systems from CEAD and recycling units that shorten the supply chain and help the environment by reducing waste. By collecting detailed data during the manufacturing process, the company is able to continuously optimize its robots for greater speed, accuracy and efficiency. Committed to environmental responsibility, Haddy uses only renewable, recyclable materials. It also introduces a truly circular system for its products through Haddy Inside RFID chips and a scalable cloud API solution, enabling responsible material tracing and recycling, sustainable production and significantly reducing its environmental footprint.

Stratasys Joins AM I Navigator Initiative

With Stratasys as another partner, the AM I Navigator is entering the next phase, which is a collaborative effort to standardize a model for AM technical maturation. With its framework, the AM I Navigator provides a structured approach to defining the current status and the steps toward the target state of industrialized AM. It builds on established frameworks for digital manufacturing, such as the Smart Industry Readiness Index (SIRI), which helps companies to assess their current level of digitalization and readiness for Industry 4.0 and to develop strategies for the modernization of their production processes.

Related Content

5 Points You Might Not Know About Hybrid CNC Machine Tools

Hybrid Manufacturing Technologies’ co-founder describes the role of hybrid additive manufacturing machines, and explores their possibilities related to heat treating, multimaterial tooling and making parts with embedding sensing.

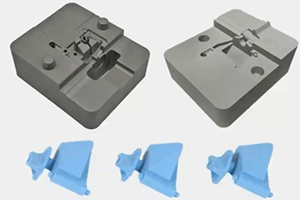

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreVideo: Robot Machining Will Complement Robot DED

Robots can do additive manufacturing. Can they do hybrid manufacturing? Precision milling of metal using a robot offers this promise.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More