3D Printing for Automotive

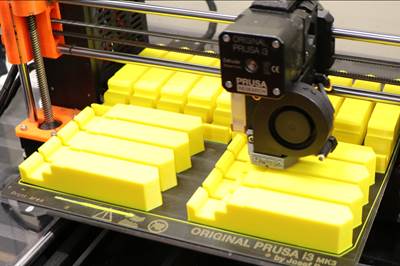

Automakers, race teams and other vehicle OEMs continue to turn to 3D printing for functional prototyping, assembly tools, forming and injection molds, and end-use parts. Electric vehicles represent a new market for additive manufacturing, and an opportunity for this technology to go farther than ever before.

ESSENTIAL READING

VIEW ALLFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read MorePhotocentric Explores How 3D Printed Battery Electrodes Could Drive Electric Vehicles Forward

Precise control of battery electrode architecture through photopolymerization opens the door to new cell geometries and lighter battery packs for EVs and more, Photocentric says.

Read MoreAs 3D Printing for Production Becomes Practical, the Attention in Materials Shifts to Practical Concerns

Recent posts relate to ensuring sufficient materials supply for production, certifying processes for AM materials, and even whether the properties of polymer AM include the ability to hold a screw.

Read MoreWhy GM’s Electric Future Is Also an Additive Future

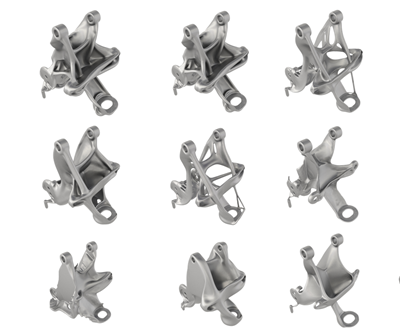

Production capacity isn’t the only reason that additive has been slow to make inroads into the automotive industry. There is a larger barrier to entry—one that General Motors and Autodesk are working to overcome.

Read MoreLatest Automotive News And Updates

Formula One Team Adopts 3D Printing Technology to Transform Component Design, Production

The Visa Cash App RB Formula One team is collaborating with Roboze to reduce weight and create parts with geometries that are impossible with other techniques.

Read MoreConsortium Successfully Implements Automated AM Production Line at BMW Group

After a three-year project time line, the Polyline project was finally completed with a fully automated operation installed at BMW’s additive manufacturing campus in Munich, Germany.

Read MoreLiqcreate Creates Flame Retardant Polymer for High Temperature Applications

Parts made with this additive manufacturing resin can withstand high temperatures without posing a fire hazard due to its self-extinguishing capabilities.

Read MoreDivergent Technologies Acquires Sigma Additive Solutions’ Software, Intellectual Property

The purchase of Sigma Additive's in-process monitoring software and IP will enhance the efficiency and quality control within the Divergent Adaptive Production System (DAPS) platform.

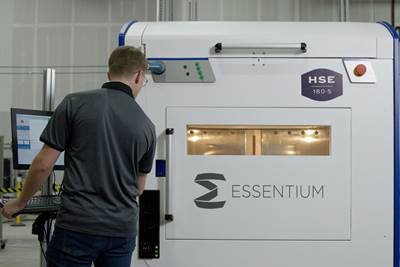

Read MoreGerman National Railway Certifies Essentium HSE Printing Platform, Materials

Essentium’s additive manufacturing solutions will enable Deutsche Bahn to increase its fleet availability through easy and fast replacement of parts and tools.

Read MoreVelo3D Qualifies Aluminum Alloy to Support Formula 1 Customers

Aluminum alloy supports Formula 1 customers by enabling the production of parts requiring high thermal conductivity and durability, and is available to print in both 50 and 100 micron layers.

Read MoreFeatured Posts

This 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

WatchIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreDo Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

Read MoreFeatured Media

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Watch8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

WatchHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

WatchFAQ: Automotive

What are examples of 3D printed automotive parts?

Examples of additively manufactured automotive parts include:

- Structural components

- Solid-state batteries

- Interior features, such as these customizable cupholders

- Heat exchangers

- Tooling for forming components and machining motors

- Brackets

- Drive housings

- Pedals

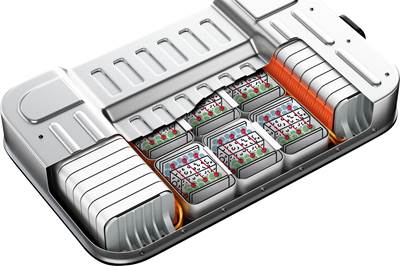

How do you 3D print a solid-state battery?

One company, Sakuu, developed a multi-material, multi-process 3D printing platform called Kavian. It combines a binder jetting type process for larger areas, and then material jetting for finer details.

Dave Peterson, who is the Vice President of Marketing and Business Development at Sakuu, describes a solid-state battery as a sandwich or a layer cake with the solid electrolyte in between the anode and the cathode. The challenge of a solid-state battery is the manipulation of thin sheets of material 20- to 30-microns thick and ensuring that these surfaces interface properly. Sakuu’s platform builds up the layers in the 3D printing process, removing the need to handle multiple, very thin sheets of material.

Source: Multimaterial 3D Printing Enables Solid State Batteries and How Additive Manufacturing Is Transforming EVs and Transportation

What are the benefits of additive manufacturing for the automotive industry?

Some benefits additive manufacturing and 3D printing bring to the automotive industry are:

- Lightweighting

- Assembly consolidation

- Unique designs and surfaces to improve performance

- Nimble workflow and prototyping