6K Additive Selected for Powder and Process Optimization Research Project

The project is designed to prove the sustainability and environmental benefits of additive manufacturing for next-generation production of aerospace and defense products with 6K Additive working alongside RTX Technology Research Center and the University of Arizona.

6K Additive, a division of 6K, has been selected by RTX Technology Research Center (RTRC) and the University of Arizona for the America Makes and National Center for Defense Manufacturing and Machining (NCDMM) EARTH project. The proposal directly addresses more sustainable production of aerospace and defense products via additive manufacturing (AM).

The EARTH Project totals $1.2 million and is funded by the Office of the Under Secretary of Defense, Research and Engineering Manufacturing Technology Office (OSD(R&E)). The proposal is expected to increase the deposition rate by at least 2 times and reduce feedstock production energy by at least 75% while maintaining part quality, providing an overall 50% reduction in energy used to produce a component using additive manufacturing (AM).

Leveraging 6K Additive’s tested track record in sustainable production of AM powder, the RTRC will utilize advanced mode-guided process development techniques, emerging commercially available laser optics and more efficient powder feedstock to optimize additive build Ti-6A1-4V material for deposition rate, feedstock reuse and recyclability. The feedstock and print process optimization will be paired with techno-economic and life cycle analyses to quantify and exploit its benefits to sustainability.

“RTX is pursuing sustainable additive manufacturing processes to produce next-generation aerospace and defense products as well as support out-of-production part replacement. As part of this plan, our goal is to introduce hundreds of additively manufactured parts to the market over the next several years,” says Brian Fisher, principal investigator for the POSAM project, RTX. “We selected 6K Additive because of their process of converting revert and used powder into high-value, premium powder, which helps us to measure quality and carbon footprint in the same project. These advances not only make additive manufacturing more sustainable but will drive down costs for production at scale.”

This POSAM approach, coupled with a rigorous assessment of its impact, is expected to dramatically accelerate the adoption of AM within the Department of Defense supply chain. The RTX, 6K Additive and University of Arizona team will prove the POSAM approach’s ability to speed print rates and reduce energy, but also its ability to streamline complex supply chains through lower cost, sustainable processes and use of flexible material sources.

“Time and again, 6K Additive continues to prove itself as having one of the market’s only tested processes to achieve new levels of sustainability and quality in a highly regulated market in aerospace and defense,” says Frank Roberts, 6K Additive president. “And much of this success is driven by our proprietary technology for processing titanium and refractory metals at scale — powering both customers and the environment by recycling scrap streams back to premium powders,”

6K Additive says it is the world’s first producer of additive manufactured powder made from highly sustainable sources — offering a full suite of premium powders, including nickel, titanium, copper, stainless steel, aluminum alloys and refractory metals such as tungsten, niobium, and rhenium.

Utilizing the UniMelt production-scale microwave plasma process, the technology spheroidizes metal powders while controlling the chemistry and porosity of the final product with zero contamination and high-throughput production. Based on a recent LCA study, the approach makes it possible to achieve reductions of 90% in energy usage and carbon emissions for its nickel-based alloys and a 75% reduction for titanium alloys.

Related Content

3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreMultimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

Read MoreRead Next

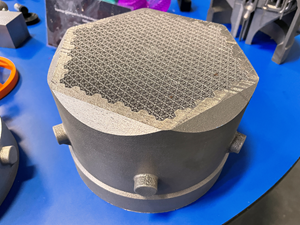

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More