AM Design May (Finally) Launch the Aerospike Engine

A team of engineers turns to additive design to create—and successfully test—“the holy grail of the spaceship movement.”

After decades of research, billions of dollars in global investment, and soul-crushing technological delays, the aerospike engine—a single-stage-to-orbit technology once dubbed “the holy grail of the spaceship movement”—may finally be getting off the ground. And the recent announcement that engineers from Monash University and Amaero successfully designed, built, and tested an aerospike engine suggests that additive manufacturing promises to play a significant role in making this moon-shot a reality.

A Little History

The aerospike is a single-stage-to-orbit (SSTO) engine, meaning that much of its greatness lies in its ability leave our atmosphere without the added payload of multiple-stage boosters. The engine’s chief attribute is its ability to maintain thrust efficiency from ground level into outer space. But despite more than 50 years of testing and $1.5 billion investment in the technology, an aerospike engine has never entered service.

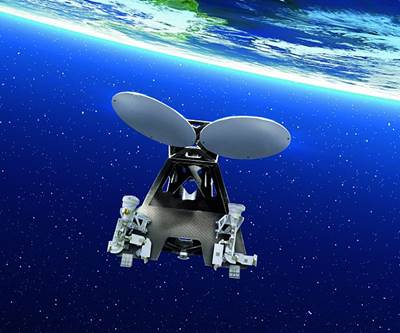

The engine employs a high-efficiency nozzle, or spike, to direct the flow of high-pressure gas emanating from the thrust cells. The surface of the spike restricts expansion of the gases against the curved inner wall of the rocket, while a cavity at the top of the spike allows a subsonic flow field to recirculate at its base. Thrust produced from the pressure against the spike combines with the recirculating flow field to produce a powerful, highly efficient engine that is not as susceptible to changes in atmospheric pressures. As the altitude increases, the pressure boundaries shift from the nozzle and upper base to the inner wall of the enclosure, which keeps the nozzle performance at near-theoretical maximum across changing atmospheric conditions.

The aerospike’s design and functionality are immensely complex to realize through traditional manufacturing methods, due mainly to the inner geometry of the rocket’s inverted-bell shape, and the complex cooling channels necessary to keep the engine from outright melting.

Yet during the 1960s, Rocketdyne, a division of Boeing, conducted extensive testing on the aerospike engine. The results of those tests were put to use after NASA announced its ambitions for a would-be successor to the Space Shuttle—a lighter, safer, more efficient SSTO vehicle it dubbed the VentureStar. In 1996, NASA selected Lockheed Martin as a partner to create the X-33, a technology demonstrator for the VentureStar. The key component of both the X-33 and the VentureStar was to be a linear aerospike engine.

But from 1996 until NASA officially cancelled the program in 2001, it was beset by cost overruns and failures. While key technological advances allowed for various successful ground tests of the engine, a series of problems, mostly unrelated to the aerospike engine itself, as well as organizational changes within NASA, slowly doomed the project. In 1999, multiple failures in the liquid hydrogen tanks proved costly and time consuming, even though two aerospike engine tests had proved to be encouraging. But as delays continued to plague the project, it became clear that, from a technological standpoint, the VentureStar was too far ahead of its time. By the time NASA declared the program officially dead in March of 2001, it’s estimated that the agency had spent nearly $1 billion on the project, while Lockheed Martin and other partners had contributed $357 million.

AM Freedoms Launch Hope

Marten Jurg, an engineer with Amaero and a PhD candidate at Monash University in Australia, says that additive manufacturing—and specifically, its design freedoms—may represent the technological breakthrough needed to finally launch the aerospike engine. The design of the aerospike’s exhaust manifold is essentially inverse to the traditional bell-shaped rockets used to launch recent space shuttles. Those rockets lose efficiency when the thrust spreads out from the bottom of the bell-shaped manifold as the craft ascends and the atmospheric pressure decreases. This is why the shuttle missions require multiple stages to reach orbit: decreasing atmospheric pressure during ascent requires different thrust capabilities than the initial booster rockets that are jettisoned just minutes after launch.

The Amaero team—which consists of other PhD candidates from Monash University—designed their aerospace engine around the additive process from the outset. Printed on an EOS M280 using Hastelloy X (a high-strength, nickel-based superalloy), Jurg says that build chamber size constraints, feature size, materials performance, and key parameters such as the angle, thickness and arrangement of features were all considered in light of the group’s collective years of experience in the alloy system using selective laser melting (SLM). Since the team took a minimizing approach, all design choices were made to reduce the amount of machining necessary for post-processing.

“Drawing from experience in the Hastelloy alloy system, we knew what was and wasn’t possible,” Jurg says. This experience informed Amaero’s design choices, and by working back and forth with the fluids engineers, the team was able to rapidly iterate and create geometries and features that would meet key performance criteria while still maintaining AM buildability. The team first focused on what Jurg calls the “big-ticket items,” such as the engine’s three-chamber design, truncated aerospike, and cooling configuration.

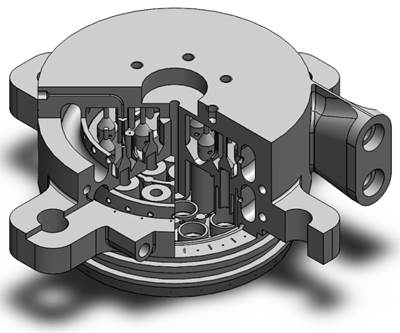

Jurg points to the conformal cooling channels as just one of the aspects of Amaero’s aerospike that would not have been possible to manufacture traditionally. (See the third image of the rendering above.) Numerous features were completely reconceptualized for additive design, including the conformal cooling, injector manifold, the elimination of high temperature seals (by making the combustion chamber a single piece), and the fluid flow path and control mechanisms. The cooling passages alone, he says, “constantly change size and orientation to cater for the specific local heat flux, which is critical to ensuring continuous operation. With traditional manufacturing methods, one may resort to brazing together tubes, but due to the curvature of the aerospike and body, the tubes would have to continuously vary in width in order to join constantly along its length.” Achieving the right manipulation of tubes in this way would be an extremely difficult process, Jurg says, one that might take many months or even years to perfect.

Since Amaero’s engine was intended to be finished in just a matter of months, the Amaero team had to radically rethink its design approach. For this they created calculation tools that allowed them to rapidly iterate through the fundamental aspects of the design and quickly converge on a design solution. “We aimed to show through this project the benefit of working with AM design from the outset, not taking a traditional design and making it work with AM,” Jurg says. “As a result, we were able to adopt designs that we wouldn’t consider possible otherwise.” While AM within aerospace is quickly becoming an accepted method of manufacturing, Jurg points out that the industry has not been as quick to adopt design for AM methodologies. “In this project, through concurrent design methodology and consolidation of components, the timeframe could be reduced significantly while also increasing the overall performance.”

The team that created Amaero’s aerospike engine have formed a new venture called NextAero to move this work forward, looking at future applications in propulsion technologies. Meanwhile, Jurg says that Amaero is using its aerospike “to show the potential of additive manufacturing to those who may not understand the process, and how by working with AM designers it is possible to build items with a new level of performance.”

While Jurg isn’t contending that additive manufacturing will rejuvenate the VentureStar program, he does believe that his team’s successful test of a 3D-printed aerospike engine will encourage other engineers to adopt AM design methodologies early in the design process. It’s the only way, he says, to take full advantage of additive’s potential.

Related Content

Two 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

Additive Manufacturing of Brackets Saves 1 Kilogram per Satellite

Because of complexity, material and quantity, spacecraft and satellite components are good candidates for additive production.

Read MoreAdditive Technology Delivers Small Satellites to Space

Researchers at the German Aerospace Center (DLR) have developed a reusable rocket engine specifically for the launch of small satellites. The complex injector heads are 3D printed which unlocks additional performance, reduces the parts count, speeds up production time, and reduces weight and costs.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More