Articles

3D-Printed Prototypes Become the Parts with Carbon Fiber Filled Filament

Utah Trikes, a retailer and manufacturer of trikes and quads, has grown its custom business using FDM Nylon 12CF to produce end-use composite parts that formerly would have required moldmaking.

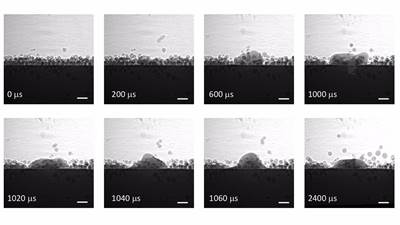

Read MoreReal-Time, High-Res Monitoring of Structural Defects in Metal AM

A team at Argonne National Laboratory has, for the first time, captured below-surface measurements of laser-metal reactions.

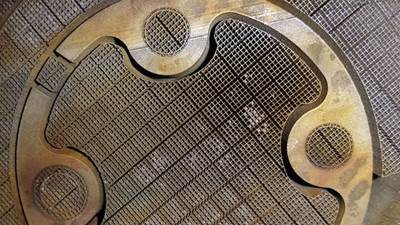

WatchUsing Hybrid AM, GE Leverages Turbine Blade Repair into Efficiency Improvement

An engineering modification that would have been impractical or cost-prohibitive in the past is realized on a machine tool performing metal 3D printing and machining in the same cycle.

Read MoreAdditive Manufacturing at EMO 2017

Here are some of the AM technologies Editor-in-Chief Peter Zelinski saw at the world’s largest metalworking show.

Read MoreInstalling a Metal 3D Printer, Part 3: Safety Risks

PADT’s third blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks and ways to mitigate them.

Read More3D-Printed Medical Drills Keep Bone Cool During Surgery

Drills made via additive manufacturing cut bones without causing thermal-induced damage thanks to internal cooling channels.

Read MoreAerospace Project Pairs 3D Printing with Investment Casting

A research project conducted by Autodesk reduced the weight of an airplane seat frame using 3D-printed patterns and investment casting in magnesium.

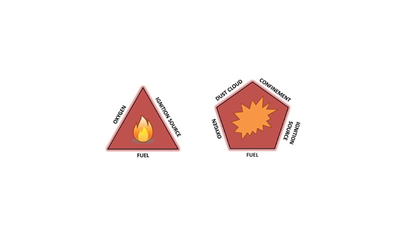

Read MoreWill My AM Part Explode?

Will my additive manufactured part explode? Not if you’re careful. Postprocessing parts built from metallic powder requires extra precautions.

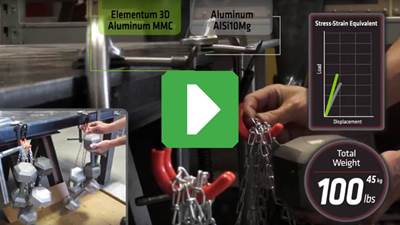

Read MoreVideo: Strength of Aluminum Metal Matrix Composite Versus Aluminum Alloy

The Aluminum MMC demonstrates a yield strength greater than 1018 steel. Additive opens the way to applying advanced materials such as this.

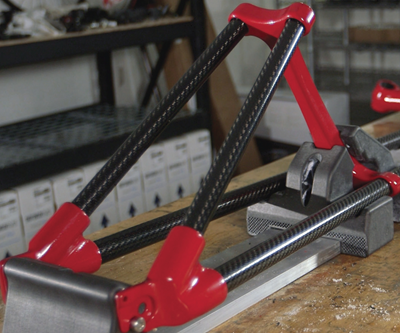

WatchVideo: 3D-Printed Composite Hooks Lifts Hundreds of Pounds

AM challenges expectations about which applications and part types call for metal and which are appropriate for polymer.

Read MoreInstalling a Metal 3D Printer, Part 2: Facilities

What facility adaptations are necessary when installing a metal 3D printer? PADT documents the steps it took to support a Concept Laser Mlab Cusing R in this second post in a five-part series.

Read MoreBeAM Demonstrates Magic 2.0 and Shows Capabilities of New North American Facility

Training, process development, applications engineering and material development will all be performed with staff and resources of Ohio facility.

Read More