Advantages of Wire Over Powder in Additive Manufacturing

Gefertec says its wire-fed additive manufacturing systems can overcome existing process limitations of powder-fed systems.

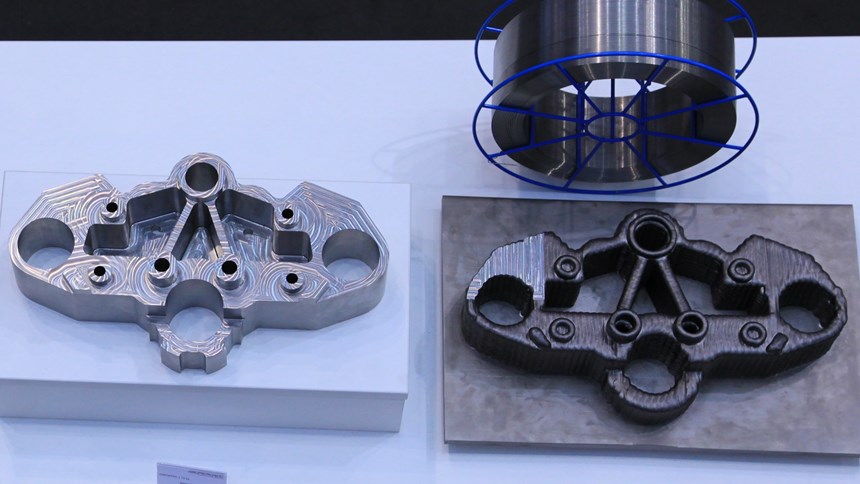

Existing metal AM processes for manufacturing components using powder and laser techniques allow for the production of complex structures otherwise not possible, but can be limited in terms of component dimension and build-up rates. Tobias Röhrich and Georg Fischer, managing directors of Gefertec (founded 2015), and their team have considered a wire-fed method that expands these procedural boundaries.

The Berlin-based company refers to its shape welding process as “3D metal print” (3DMP). This process is based on the same technology found in arc welding and uses metal wire to print components consisting of individual welded beads, similar to electron beam additive manufacturing technology. "Our initial thinking was more in the direction of laser technology, but then we realized that whatever is possible with a laser is also possible with electric arc," said Röhrich at EMO 2017 in Hanover, where Gefertec was presenting the 3DMP process to the public for the first time. "Arc welding technology is a robust and simple technology that allows the creation of near-net-shape components with high build-up rates. There is no limit to part size and, in contrast to electron beam welding, there is no need for a vacuum chamber."

High Build Rates Reduce Costs

The near-net-shape blanks are limited in terms of resolution and complexity compared to powder bed processes and must always be postprocessed using subtractive manufacturing technologies such as milling. However, the 3DMP process also offers a number of advantages, according to Röhrich. It eliminates the cumbersome handling of powder; in addition, most standard materials are already available as wire and at appreciably lower costs.

In comparison to other additive manufacturing methods, there are also a multitude of norms and guidelines already available to which wire- or arc-based processes can be applied. "The biggest advantage, however, is the very high build rate, which is currently up to 600 cm3 (aluminum) per hour depending on the material used," says Röhrich. "For titanium/nickel-based alloys and steel the build-up rate is 450 cm3/hr., thus allowing us to economically produce larger components from these materials."

…the use of specific manufacturing strategies, process monitoring and temperature detection systems can effectively counteract residual stresses and warping, ensuring component properties comparable to those machined from solid metal.

Similar to most common additive manufacturing processes, the 3DMP process starts with a CAD model, which is then converted into machine code using appropriate CAM software. The metal wire is melted and applied to a substrate during the printing process, using arc welding technology in conjunction with a linear axis system and an optional rotary swivel unit. Using this principle, welding passes are made parallel to as well as on top of each other, thus allowing the component to be generated in surface and height.

Component resolution is determined by the smallest physically possible size of the welding bead. According to Gefertec, this varies depending on the wire alloy; however, is usually no smaller than 1.5 mm in height and 2.5 mm in width. Currently, the wire diameters used are between 0.8 and 1.6 mm, but smaller diameters down to 0.4 mm are in the testing phase, according to Prof. Jean Pierre Bergmann, head of the production technology department at the University of Ilmenau and Gefertec cooperation partner.

Experiments here have proven that correlations of process parameters, temperature and structure do in fact exist and that homogeneous material properties can be achieved at low energy levels. According to Bergmann, the big challenge compared to classic fusion welding is the fact that the weld is continuous on the weld metal but not on the base material. Moreover, comparatively high energy input, especially for smaller components, means an increased risk of oxidation due to the larger areas having more critical temperatures. According to Bergmann, however, the use of specific manufacturing strategies, process monitoring and temperature detection systems can effectively counteract residual stresses and warping, ensuring component properties comparable to those machined from solid metal.

Tests with materials such as nickel-based alloys (alloy 718, for example) demonstrate that the adjustment of the mechanical material parameters for additively manufactured components can also be accomplished by using downstream aging, thereby preventing thermal cracks or pores. For aluminum alloys, the appropriate energy input can be targeted during 3D printing and subsequently during heat treatment to ensure excellent material properties. "A well-adjusted process ensures that a pore-free joint with excellent strength properties can be achieved," Bergmann says.

Three- or Five-Axis Machine Produces Near-Net-Shape Parts

As a way of combining the final machining step with the welding process, Gefertec has developed the GTarc machine, which is available as a three-axis variant for component sizes up to approximately 3 m3 or five-axis for workpiece sizes up to 0.8 m3. The machine can be fitted with a hybrid module which allows for milling or drilling operations for hard-to-reach areas after the complete build-up (such as internal cooling channels). Final machining has to be performed on a separate machining center.

Specially developed CAM software uses the component’s CAD file to generate the data which the CNC controller uses for precise positioning of the welding head. The machine produces the near-net-shape component fully automatically. The finishing process is then carried out using conventional CNC milling technology. The customer can, for example, retrofit the three-axis variant with the swivel turntable and thus convert it to a five-axis version. According to Gefertec, the cost for a GTarc machine is similar to that of a smaller turn-mill center and is clearly less than the cost of comparable AM machines.

The use of materials for the 3DMP process is highly optimized, leading to considerable cost advantages, especially for expensive materials such as titanium, says Röhrich. This material optimization can reduce manufacturing costs by 60 percent, depending on the application. For example, a bearing block milled from solid 1.4305 with a starting weight of 85 kg has a material cost of 1,000 euros. The milling cost for this component is approximately 3,500 euros (with a chip percentage of 80 percent), resulting in a total cost of 4,500 euros for the finished part weighing 18 kg.

In contrast, an additively manufactured blank weighing 25 kg could be produced with a build-up rate of 325 cm³/hr. in 6.5 hr., with a cost of approximately 750 euros. Using this blank, the chip percentage is reduced to 28 percent, lowering the milling cost to about 1,250 euros and total production cost to about 2,000 euros, Röhrich says.

"For chip volumes greater than 30 percent, the process is well worth it and it can be used to replace sand die-cast prototypes or can be used for small series," says Röhrich. "As a result, we have developed an economical additive process that is limited in geometric complexity, but is ideally suited for the production of near-net-shape blanks of basic and medium complexity."

Related Content

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More