Articles

How Test Swabs Became 3D Printing's Production Win: The Cool Parts Show #15

Nasopharyngeal swabs for COVID-19 testing are one of the best production cases for 3D printing we've seen, pandemic or otherwise. Why AM is winning on speed, functionality and collaboration.

WatchDrone Engine Maker Illustrates How Additive Manufacturing Well Suited to OEMs

This small company making small engines sees big wins from metal AM in terms of both product performance and responsiveness to the market. Here, size isn’t a factor in succeeding with AM — the application instead shows how the capability is at its best when it can serve both production and design.

Read MoreAdditive Manufacturing versus COVID-19: Protecting Your Ideas for Protecting Others

Reporting from the front lines of the fight against Coronavirus – battling liability and IP issues.

Read MoreMap of 3D Printing Service Bureaus Across the U.S.

More than 200 3D printing service bureaus in the United States are listed on this custom Google Map, created to help fill supply chain gaps related to coronavirus.

WatchHow PrinterPrezz Aims to Realize a Manufacturing Model Tailored to Medical Devices

3D printing for orthopedic implants enables innovation and better patient outcomes, but a new type of manufacturer may be needed to realize this promise. A startup focused on implant development, approval and production via additive manufacturing includes surgeons among its founders.

Read MoreLeader of New Jersey PPE 3D Printing Effort Tells Volunteers, “Stop Completely”

“PPE Made in the USA” delivers 5,000 3D printed face shields produced and distributed by 50 volunteers. As emergency passes, a high school STEM teacher’s response to the COVID-19 crisis reaches its conclusion.

Read MoreDrone Engine Replaces 13 Parts With 1: The Cool Parts Show #14

Cobra Aero discovered an opportunity for redesign it might never have found without the COVID-19 interruption providing time for product development via 3D printing. The Cool Parts Show explores how additive manufacturing is advancing during the coronavirus crisis.

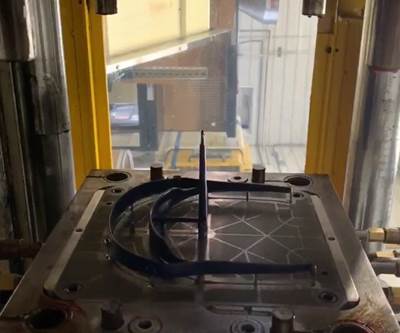

WatchHow 3D Printed Tools Add Value at This GM Plant

General Motors’ Spring Hill, Tennessee, facility is finding opportunities to replace conventional tooling components with 3D printed alternatives made in house. The result is cheaper tooling on a shortened timeline, with better functionality.

Read More3D Printing and Coronavirus: U.S. Additive Manufacturers Share Their Experiences

The COVID-19 outbreak has brought both setbacks and opportunities for American manufacturing. 3D printing companies share their stories.

Read MoreTool Steel Alloy Combines 3D Printability with Hardness, Ductility for Tool and Die

Formetrix’s L-40 for powder bed fusion 3D printing enables complex mold geometries at efficient print speeds, with low risk of cracking.

Read MoreFrom Idea to PPE Product in 10 Days: The Cool Parts Show #13

Fitz Frames' custom 3D printed glasses have turned out to be a launch point for an item of personal protective equipment (PPE) used in the fight against COVID-19.

WatchPPE Shortage Catapults Human Solutions Tech into Production

The organization was intended to solve unmet needs in the local community. Its founder didn't anticipate that its first project would be face shields.

Read More