Westec Plastics Corp. (Livermore, California) is a 54-year-old custom molder that operates 23 injection presses ranging in size from 25 to 553 tonnes. Specializing in molding high-temperature engineering thermoplastics for the medical device market in ISO Class 6, 7 and 8 cleanrooms, Westec also serves customers in the consumer and government segments.

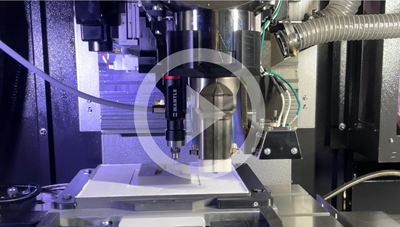

The company builds some of the molds it uses and outsources the rest to local toolmakers. As such, it has been specifying metal AM technology for the last few years for mold inserts with conformal cooling features that were produced by toolmakers and local service bureaus. Westec recently took possession of the first production metal AM printer from Mantle Inc. , enabling the company to now design and print conformally cooled mold inserts in-house.

The company has used polymer AM technology for the past seven years — the last four in-house with an Ender 5 Plus FFF printer from Shenzhen Creality 3D Technology Co. Ltd. Initially, polymer AM was used to prototype parts. Later, use was expanded to produce part fixtures.

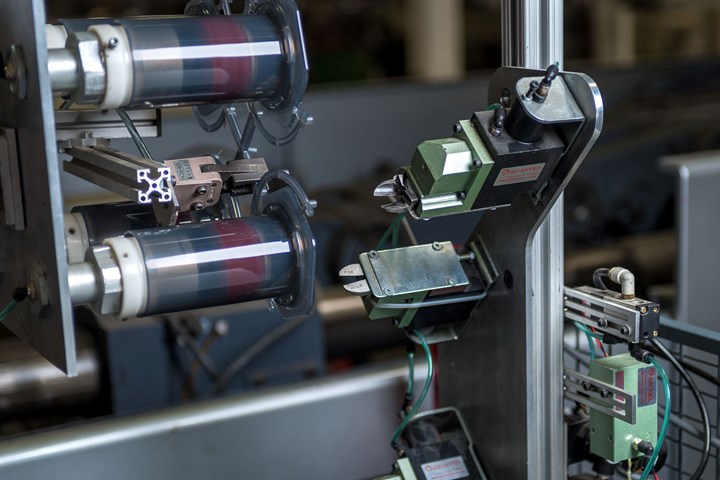

Custom injection molder Westec Plastics Corp. operates 23 injection presses (some of which are shown at top) and uses additively manufactured EOAT and fixtures produced on its own in-house printer or those of local service bureaus. Shown on the bottom is an EOAT that pulls molded parts for the consumer segment from a four-cavity injection tool and clips off the runners. Photo Credit: Westec Plastics Corp.

“We work with a lot of medical customers and they frequently modify designs, so it’s really nice to be able to print sample parts and have something physical to hold, as everything looks doable when it’s on the [computer] screen,” Cory Vohs, Westec director of molding, explains. “As we gained experience, we slowly used our printer to try other things, including printing PLA fixtures to hold molded parts for pad printing. Additively manufacturing these parts is certainly faster and less costly than keeping our CNCs running.”

Vohs adds that simple and smaller fixtures are printed in-house, but larger and more complex ones are produced through external resources. The company also uses EOAT in conjunction with cobots to help molding technicians quickly and safely demold parts.

“Although we do try to use off-the-shelf automation components whenever possible, having the ability to design a fixture in-house and either print it ourselves or have it printed nearby is a big advantage to us,” Travis Meeks, Westec vice president of tooling, adds. “This way, we don’t have to interrupt our own tool shop, and we can get the component much faster and at lower cost than if we had to wait weeks to have an outside tool shop produce it conventionally. Plus, a polymer additive fixture isn’t going to damage our molded parts.”

More From This Author

Peggy Malnati is a Detroit-based contributing writer for CompositesWorld magazine, for which she primarily reports on automotive and ground transportation. SUBSCRIBE HERE

Related Content

Mantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreRobot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreRead Next

Conformally Cooled Injection Mold Reduces Cooling Time by 55 Percent

With Renishaw’s help, Kärcher ended its production bottleneck using 3D-printed molds with conformal cooling channels.

Read More3D Printed Human-Operated End-of-Arm Tooling Promotes Safety and Throughput

Toolmaker and injection molder Zero Tolerance developed a manual tool to enable an operator to quickly place inserts into a mold.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read More

.jpg;width=70;height=70;mode=crop)