What the Coronavirus Crisis Will Mean for Additive Manufacturing

In the response to COVID-19, 3D printing demonstrated some of its strengths, but not all of them. However, the full effect of this crisis for AM is still to come.

Since the onset of the coronavirus crisis, additive manufacturing (AM) has been busy. The Additive Manufacturing team has been busy keeping up. The AM response to the crisis, with 3D printing users stepping forward in many ways to address the shortage of both medical personal protective equipment (PPE) and ventilators, has developed and changed so rapidly that senior editor Stephanie Hendrixson and I hit upon posting weekly video check-ins (filmed from our respective homes due to stay-at-home orders) as our best tactic for explaining all we’re learning related to the advance of AM in the crisis and its encounters with stakeholders such as the FDA. In recent weeks, additive manufacturing has stepped into a prominent, unexpected role.

Has it been additive’s moment to shine?

The crisis is far from over. However, AM’s response to it is far enough along that it is possible to see an answer to this question, and the answer is mixed. Has it been AM’s moment? Yes and no.

Yes, because 3D printing demonstrated one of its strengths in this crisis: the ability to deliver parts quickly. Because it needs no tooling and little in the way of setup and programming, AM is the manufacturing process able to deliver a needed part in the shortest lead time. AM offered face shields when no other providers had them, prototypes for new medical masks and the means to produce those masks, plus the means for making the splitter multiplying ventilator capacity that was approved by the FDA. Among production processes, AM is the first responder.

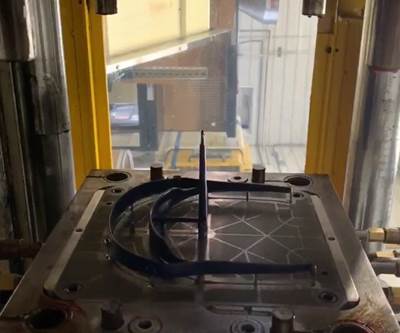

How reshoring and additive manufacturing go together: Meld Manufacturing of Christiansburg, Virginia, was able to 3D print this aluminum 6061 part, more than 55 inches in diameter, in just a few days. According to the part's customer, obtaining the component as a forging from an overseas supplier would have involved a lead time of up to 2 years even before the pandemic.

Yes as well, because even before the crisis had fully arrived for the United States, it was already disrupting supply chains because of its effect on suppliers in China. AM gave companies an alternate way to get production, and get it immediately, without waiting to tool up a different supplier.

But here is where the answer shifts to no: Additive manufacturing hasn’t played to all its strengths in this crisis, or even most of them. Additive is best for part designs that can only be made through AM — new products and solutions that exist only because AM makes them possible. That doesn’t describe the urgent work this year. PPE, ventilators — these are existing products conceived for existing methods. The challenge was just to make a lot of them. Conventional manufacturing processes took longer to ramp into the effort, but once they got going, they often provided the more effective response.

The fitting analogy might be this: In 2020, AM went to war. In a war, artists, dancers and musicians might serve with honor as soldiers, their true gifts not used. Additive entered the effort and did what it could, its full value not realized.

But again, the crisis is not over, and its full impact has not yet been seen. Its lessons have not yet been acted upon. Consider the second “yes” above, about supply chains. This year, companies experienced the vulnerability resulting from relying on distant suppliers. And just why was it again that we left ourselves having to fear we might not be able to produce the medical equipment we need?

The crisis of 2020 has shown the value of keeping manufacturing close. It has shown the value of domestic manufacturing, making the case for reshoring. And reshoring and additive manufacturing go together. AM is the production process least affected by labor cost, and the process offering the most flexibility and freedom to manufacturers now ready to rethink not just where they produce, but how.

Did 2020 provide AM with its moment? Yes, in a way. In part because of what this year is teaching, I expect AM to find its moment in 2021, 2022, and through the next few years to come.

Related Content

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read MoreWhat Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

3D Printed Device Allows Multiple Patients on One Ventilator

Emergency authorization from FDA allows for use of device permitting four patients to use a shared ventilator. HP involved in mass production via additive manufacturing.

Read More3D Printing and Coronavirus: U.S. Additive Manufacturers Share Their Experiences

The COVID-19 outbreak has brought both setbacks and opportunities for American manufacturing. 3D printing companies share their stories.

Read More