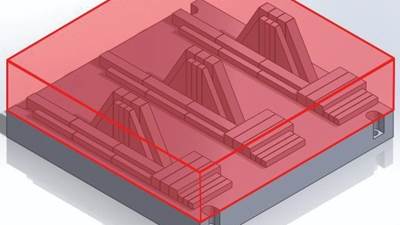

The CNC machining capabilities at 3rd Dimension Industrial 3D Printing allow the company be be aggressive in its use of support structures for metal printed parts like this bracket. In turn, this increases the chances of a successful print and a quality part.

Of all of the things that people in the additive manufacturing (AM) community will remember about 2020, the collective effort of AM professionals to pivot toward the manufacture of personal protective equipment (PPE) surely will be one of them. The eagerness to help and the agility that 3D-printing businesses have displayed has been eye opening and reassuring, even if the type of PPE that hospitals require doesn’t always align with devices that can be printed.

Compare that to 2013, which at the time may have seemed the most auspicious year for additive manufacturing. AM was having its moment in the sun, soaring from lofty media hype into a stratosphere of impossible promises. At that time, Bob Markley was just finishing a 10-year stretch as a professional racing engineer followed by work at Rolls Royce and General Motors, the latter of which was consolidating its workforce to Pontiac, Michigan. Unable to relocate his family from Indiana, the then-31-year-old Markley wrote up a business plan centered around additive manufacturing — a technology he’d barely used, but one that appealed to the experimental engineering style he’d developed through racing.

2013 was the year that Markley went all-in on AM, launching 3rd Dimension Industrial 3D Printing in a 1,800-square-foot facility outside of Indianapolis. After opening for business, he quickly partnered with 3D Systems and brought in the company’s ProX 200 — a laser powder bed fusion machine he still refers to today as his workhorse. Sustained financially by his original loan and a small but growing base of customers, Markley purchased a second ProX 200, followed by a 300 model and later a 320 that he beta tested for the company.

Again and again over two years of printing parts, turning knobs and experimenting with parameter controls, Markley’s experience with professional racing proved to be invaluable. As a beta user for the ProX 320 he felt the same freedom of experimentation as he did when reengineering components for high-performance race cars: Both were custom machines that required finely tuned calibration. The work pace was incredibly fast. Data interrogation — a critical tool for calibrating Indycars and metal 3D printers — took place in a compressed timeframe.

In early 2017, the world of auto racing gave back to Markley once more. An old friend from Markley’s former racing days called with the news that his racing team was shutting down. His crew was selling its machine shop and everything in it.

He had called the right person. Markley bought nearly all of the equipment and hired a machinist.

Bob Markley (left) peers inside his company’s Additive Industries MetalFab1.

Within a few months, 3rd Dimension Industrial 3D Printing was packed not only with 3D printers but also a small fleet of CNC machines. Suddenly the company had not only enough CNC equipment to finish machine the parts it produced additively; it now had the capabilities of a standalone CNC job shop.

It’s this fact allows 3rd Dimension to operate in a way that not many AM service bureaus can. It also helps account for Markley’s willingness to say things that not many AM business owners say. “You can't just print for the sake of printing,” Markley says.

Today 3rd Dimension Industrial 3D Printing resides in an expansive new building — 27,000 square feet with adjacent rooms for printing and machining. During a visit in late 2019 we found that, as 3rd Dimension quickly ramps up for additive production, it’s the company’s fully developed machining capabilities that have created competitive advantages that go beyond post-processing 3D-printed parts.

Establishing a Process

The first thing that stands out when touring 3rd Dimension’s print production floor is how expansive and uncluttered the space is. In a hangar-like room that houses the company’s 3D printers — including an EOS M280, four ProX machines by 3D Systems and a Stratasys Fortus 250MC — there is enough floorspace to fit double that number. (“Come back in six months,” Markley says, hinting that that is indeed the plan.) Quick note: a recent addition to 3rd Dimension’s printer lineup is an Additive Industries MetalFAB1, a highly automated, modular powder-bed system with multi-material as well as post-processing capabilities. The investment is further recognition that 3rd Dimension is aiming for production scale, its machine shop notwithstanding.

Markley and his colleagues custom designed 3rd Dimension with ESD floors, humidity control and dedicated space for powder handling. The room adjacent to the machine shop houses two large compressors that can each serve the shop’s needs if one goes down, and there is a dedicated transformer stationed outside that feeds 3rd Dimension enough electricity to power a small city.

The author and Bob Markley at 3rd Dimension Industrial 3D Printing.

The machine shop side of 3rd Dimension is equally massive, providing plenty of room for the company’s five Haas HMCs and VMCs, two Mitsubishi Electric wire EDMs, a manual mill and lathe and an in-house vacuum heat treat furnace. To be clear, the first priority for these machines is to finish-machine the metal parts being printed in the next room, and the majority of our conversation with Markley was focused on printing rather than machining. He pointed out that 3rd Dimension has already secured several aerospace customers, in part because of the company’s ability to provide part traceability down to the print location and orientation on the build plate. In fact, Markley considers this to be critical to his overall production strategy — so much so that he’s applied that same level of traceability to a low-volume, high-value consumer product his company is producing on the ProX 320.

Redundant air compressors located nearby 3rd Dimension’s machine shop.

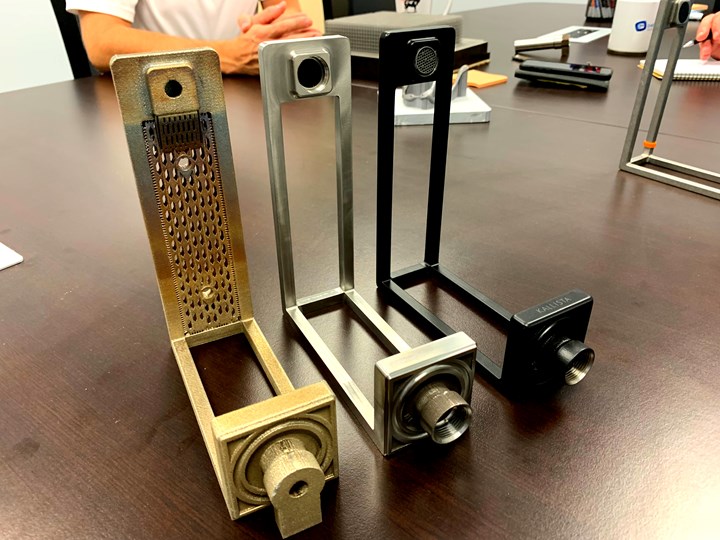

The Kallista Grid faucet, which 3rd Dimension prints out of 316 stainless steel powder in batches of six, is a study in negative space. It is the MC Escher drawing of bathroom hardware — a shape composed of a simple geometry manipulated into a seemingly impossible path. Where a typical faucet features a central spout for water to flow through, the Grid is composed of a rectangular, hollow metal frame that bends at 90-degree angles both horizontally and vertically. Water flows to the aerator via interior fluid channels printed within the rectangular frame — a design that can be realized only through 3D printing.

The Kallista Grid faucet shown in three states of production: newly printed, finish-machined and after powder coating.

From printing to threading to finish machining, the faucets — which typically retail for $6,000 and won an international design award in 2018 — are produced almost entirely at 3rd Dimension. Everything except powder coating and assembly happens there.

In many ways, the Grid faucets are a perfect test case for 3rd Dimension’s production capabilities. Markley and his team worked through several iterations that tested different build angles and orientations, laser speed, and the number of parts to print simultaneously. Because the company doesn’t have to outsource for machining, the team can be aggressive while designing support structures — structures that will anchor the part firmly to the build plate and increase the chance of a successful print — and simply turn to milling or EDM for their removal. Markley also found that he could run a fast parameter set on the ProX 320 that cuts down on printing time and relies on his in-house machining processes to achieve the smooth aesthetic surfaces the part requires.

3rd Dimension’s CNC machines reside in a large space adjacent to its printing operations.

It’s worth noting that the complexity of the Grid isn’t limited to its internal geometries and print variables. The number and orientation of the different faces that require machining is itself a challenge. And once again, having both printing and machining operations in-house provides a unique advantage: the opportunity to print workholding structures onto the part that can be removed prior to finish machining.

From part traceability, to the design of workholding and support structures, to the print parameter sets to finish machining operations, the strategies and processes that 3rd Dimension has in place for the Grid faucet clearly surpass the level of complexity involved with producing typical consumer products, even a 3D-printed ones. But following this process for the Grid has allowed Markley and his team to develop and prove out a systemized approach to the company’s overall production process. So, when the next prospective aerospace customer comes along, Markley can point to the Grid and say, “Here is how I manufactured faucets to a level of quality control and process documentation that faucets don't require. And I did that for a reason: to show you what your production process will look like.”

Recession-Proof

Beyond offering supply chain integration and cost savings to customers, installing a machine shop next door to its printing operations also provides an existential benefit to 3rd Dimension. Put simply, it increases the chance of the company’s long-term survival. What was true in 2008 will be true of the next major recession: a sustained economic downturn will drag down many shops that don’t have a diverse customer base and solid financials.

But the next major recession will also expose the degree to which additive manufacturing is recession-proof. Will the perception that additive manufacturing is “experimental” drive companies to retreat from it? Or will its potential for design consolidation and time and cost savings provide cover during an economic downturn?

For 3rd Dimension, its machine shop serves as a hedge against any potential retreat from industrial 3D printing. And no matter what happens, the shop carries value as a secondary revenue source for what is primarily an additively focused business. In the worst-case scenario — a major recession results in a retreat from additive manufacturing — it’s entirely possible that 3rd Dimension can keep its lights on via its machining work. And if the opposite occurs, the company can rightly tell potential customers that, yes, you can use us for additive manufacturing and we can provide your machined parts, too. Markley can also boast to potential customers that 3rd Dimension represents just one supplier in your system for additive parts. He can say that 3rd Dimension will just take care of all of the necessary steps under one roof.

Or under various roofs together.

In July of 2018, 3rd Dimension Industrial 3D Printing partnered with Generation Growth Capital (GGC), a business investment fund focused on small-to-mid-sized manufacturing, service, and distribution businesses. The company’s portfolio includes high-end five-axis machine shops and other businesses that Markley says can assist with strategy, networking and establishing a platform to serve a broad array of customers. GGC helps handle the accounting and legal functions of 3rd Dimension, and, because of the other manufacturing businesses in GGC’s portfolio, essentially serves as a risk mitigator for 3rd Dimension’s customers.

GGC also bolsters Markley’s argument that if a part can be manufactured through machining, it should be. If a part requires complex five-axis machining, or if 3rd Dimension has a high-volume order for machined parts, the company can turn to a GGC partner to handle operations or take on its overflow. Suddenly, 3rd Dimension has enough machining capacity to allow Markley to feel like it's his job — as a metal additive manufacturing production resource — to be prepared to find an alternative to additive for any potential job that comes to him.

Because in spite of all recent technological advances in 3D printing, additive is difficult. It requires process development. It's costly. All of these factors only increase the value of having machining capability. On the other hand, when 3rd Dimension decides that a part should be produced additively, the company’s machining capacity serves as proof that additive is the right way to go. Clearly, the company is ready to make money off of the part through machining when machining is the better option. Markley points to recent developments in commercial aviation as evidence supporting his strategy.

These 3D-printed channels are similar to those printed inside the Kallista Grid faucet.

“This has been an eventful year in the aerospace sector, and one that has affected many suppliers,” Markley says. “And more broadly, we've seen the numbers about manufacturing in this country decline, and we’re seeing our aerospace customers trying to solidify their supply chain. That said, not everyone is willing to explore options with additive manufacturing. So it's nice to have both sides of the shop, if you will, in terms of stabilizing revenue.”

As 3rd Dimension seeks new aerospace customers for its additive business, Markley can make the case that his company offers stability through the machining work that it can be counted on to handle in addition to 3D printing. In other words, it can offer the right technological application for the right project.

“Supply chain management in and of itself is expensive,” Markley says. “So when we talk to our customers who say that they've got 8,000 to 10,000 vendors, the pure 80/20 rule says that 20 percent of those companies are doing 80 percent of that work. Which means that thousands of those vendors have only one part number. Consolidating that work is a huge opportunity for us. And we can take advantage of that by showing our customers that we've got the strategy, we've got the financial backing, we've got the space.”

Related Content

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Five-Axis Machining Complements AM

Intricate components made through AM go directly to a five-axis machine as part of a service combining additive and subtractive processing.

Read MoreWhy Does My 3D-Printed Part Cost So Much?

The machine, the facility and the material are just three costs behind the price tag.

Read MoreThermwood Hybrid Machine Produces Near-Net-Shape Parts

Rapid 2019: Thermwood’s Large Scale Additive Manufacturing (LSAM) system uses both 3D printing and machining to produce a near-net-shape product.

Read More