ExOne Using Metal 3D Printing with Controlled Porosity for Reusable Filters in Response to Coronavirus Crisis

Collaboration with University of Pittsburgh applies binder jet to produce an alternative to disposable masks that are in short supply.

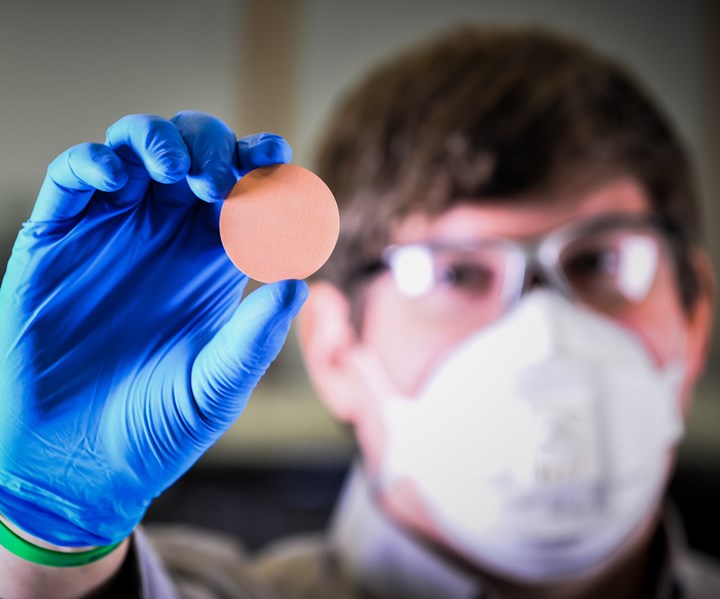

ExOne R&D Manager Kyle Myers, PhD, shows a 3D printed porous copper filter that is sterilizable and reusable. The filter fits into a cartridge designed by the University of Pittsburgh. Binder jet is key to realizing this metal alternative to disposable PPE media, as described below.

Metal additive manufacturing (AM) technology provider ExOne is working with the University of Pittsburgh to develop an emergency solution for the medical mask shortage in which the filtering component is reusable rather than disposable. The solution relies on the controlled porosity of binder jetting to create reusable filter cartridges made of metal.

Masks used to protect medical personnel from viruses are typically disposable. As a result of the COVID-19 crisis, these masks are among the medical personal protective equipment (PPE) that is in short supply. An alternative is respirator masks with filters, but these filters are also disposable and subject to short supply. Even 3D printed solutions to date have featured this shortcoming: They stretch the supply of disposable media rather than offering an alternative. The ExOne solution is different: Nothing is discarded because the metal filter can be sanitized and reused.

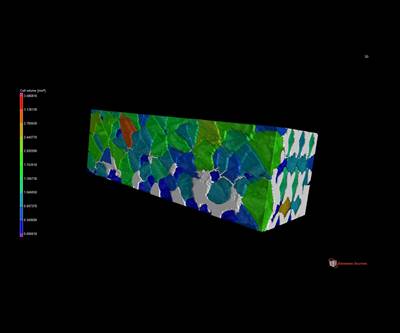

The ability of a metal part to perform this function — allowing air to pass but not a virus — relies on binder jet technology, and its ability to deliver precise porosity values. Various metal AM technologies offer controlled porosity, but binder jet, metal AM with no melting, allows for porosity that is particularly finely controlled.

While binder jetted metal is typically sintered to full density, some applications such as this require a specific level of porosity as part of their design.

ExOne’s binder jetting technology uses an industrial printhead to selectively deposit a liquid binder onto a thin layer of powdered material, layer by layer, until a final object is formed. The object is then sintered in a furnace to dial in the specific porosity level. While binder jetted metal is typically sintered to full density, some applications such as this require a specific level of porosity as part of their design.

ExOne has 3D printed a variety of metal filters in copper and stainless steel to test different porosities, airflows and filtration capabilities.

ExOne has 3D printed respirator filters in two metals — copper and 316L stainless steel — and a range of porosity levels for use inside a unique cartridge designed by the Mechanical Engineering & Materials Science department in the University of Pittsburgh’s Swanson School of Engineering. Initial testing for airflow and filtration efficiency is currently underway, and the filters are being optimized with the goal of adhering to an N95 respirator standard.

“Our team has been working urgently to expedite this promising and reusable solution for medical personnel on the frontlines of fighting the COVID-19 pandemic,” said John Hartner, ExOne CEO. “Once approved, we can print these filters in a variety of sizes for respirators, ventilators, anesthesia masks or other equipment.”

The solution is being optimized with the goal of adhering to an N95 standard. The filter can be printed to fit inside respirators, ventilators, anesthesia masks or other equipment.

To test filters in different metals and porosities, the research group is using CT scanning to analyze microstructure and porosity of the filters. Software developer Ansys, also based in Pittsburgh, is providing computer simulation support to analyze and optimize the performance of the filters.

While copper and stainless steel filters are currently being tested, copper is known to have antibacterial properties. One 2015 study funded by the Department of Defense revealed that copper alloys contributed to a 58% reduction in infections. COVID-19 research also suggests the virus dies faster on copper than on other surfaces.

Related Content

GE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreVideo: Controlled Porosity Can Be Functional Advantage Realized via 3D Printing

A wall of metal that looks solid is actually 90% dense, allowing gas to pass through. Mold venting is one application.

Read MoreCT Scanning Reveals What Isn’t There in 3D Printed Parts

3D Engineering Solutions offers CT scanning as a powerful nondestructive testing (NDT) solution for inspection. For 3D printed parts, sometimes revealing the space inside can be just as valuable as mapping what was printed.

Read More