Aerospace

Does AM Favor Integration?

Arconic, one of the companies launched in the separation of Alcoa, combines operations from metal powder production through postprocessing within a single company. Additive manufacturing perhaps uniquely benefits from bringing this range of capabilities together, since success in AM relies on more than 3D printing.

Read MoreSlideshow: Inside the New Honeywell AM Facility for Reactive Metals

Seven machines currently committed to aluminum expand the company’s capacity to 3D print both tooling and parts. One of the photos illustrates a safety measure addressing reactive metals.

Read MoreAdditive Manufacturing at TRAM 2016

The September aerospace conference will include additive manufacturing as a trend and tool for the industry.

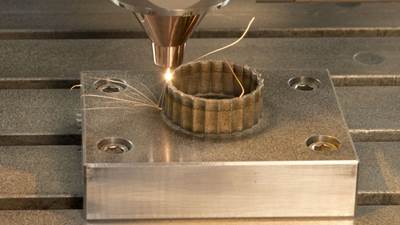

Read MoreIntegrating Additive Without Inhibiting Machining

Can AM be added to a CNC machine tool while keeping the machine’s cutting capabilities fully intact?

Read MoreAdditive Manufactured Components Reach Jupiter

The Juno spacecraft includes titanium waveguide brackets made through AM.

Read MoreShould There Be an ISO System for AM? Hear UL’s Recorded Webinar

UL’s Christopher Krampitz discusses adapting quality management systems to fit the needs of additive.

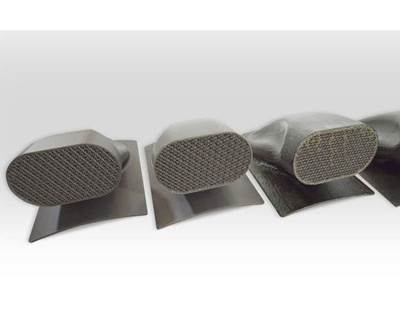

Read MoreUsing 3D Printing for Composite Molds and Tools: The Trend Continues

3D printing is becoming more common in the aerospace tooling realm. Production tooling can be made quickly and on-demand, which helps the tooling industry keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read MoreAM System Using TIG Welding and Robot Relies on Flexible Enclosure for Gas Protection

The WAAM system has demonstrated the ability to produce a titanium aircraft part, but titanium in particular requires protection against oxidation.

Read MoreReverse Engineering and 3D Printing: A Practical Solution

A contract manufacturer routinely reverse engineers and 3D prints prototypes of aerospace legacy parts for more confident production.

Read MoreU.S. Military Officers Cautiously Optimistic On AM for Repair Parts

The challenges of worldwide 3D printing by the military include confidence in AM processes and cybersecurity. The rewards of overcoming these will include improved affordability, improved repair capability and greater military readiness.

Read More