Vibration Compensation Could Increase Use of Robots for 3D Printing

Ulendo is working to apply its vibration compensation algorithm for FFF 3D printers to robots, which could expand the use of robots for 3D printing.

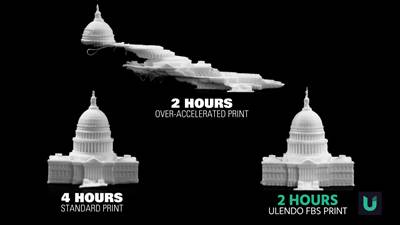

Ulendo is a startup that produces vibration compensation algorithms for manufacturing equipment. It launched with a product now called Ulendo VC, which enables FFF printers to run up to five times faster while maintaining part quality. Image provided by Ulendo.

When I covered Ulendo two years ago, writing about their vibration compensation solution for FFF 3D printers (now called Ulendo VC, for “vibration compensation”), founder and University of Michigan mechanical engineering professor Chinedum Okwudire discussed applying this technology to other machines, including additional types of 3D printers and robots. In the years since, the company has expanded beyond vibration compensation into heat compensation for LPBF, and expanded the availability of its Ulendo VC product from 3D printer manufacturers to end users with the launch of Ulendo Calibration-as-a-Service. It now has a fourth product in its pipeline, Ulendo VC-R (vibration compensation for robots), which could in turn aid 3D printers that use robots as a platform.

Ulendo’s vibration compensation algorithm can be applied to other machines, including robots that are used in 3D printing, such as this system from CEAD installed at AES. Vibration compensation for 3D printing robots is more complex than 3D printers because the vibration patterns change based on the robot’s position. Photo | Additive Manufacturing Media

Not-So-Good Vibrations

Vibration affects robots in much the same way as FFF 3D printers. “It's the same problem showing up in different ways for different applications,” he explains. Vibration in 3D printing robots can result in long cycle times and quality issues.

The primary strategy for mitigating vibration in robots is the same as gantry-style 3D printers — moving the machine slower. Adding friction to damp vibration is another option, though this causes additional wear and tear on the robot and adds to operating costs. Okwudire also notes that many of the robots used in 3D printing applications can often handle heavier payloads than one might expect for a robot carrying only a 3D printing head. He says that, according to the CEO of one company that uses robots for 3D printing, these larger robots help reduce vibration.

Ulendo’s solution compensates for a machine’s vibrations instead of managing them. It does this by “tricking the machine,” as Okwudire describes it. Traditionally, Ulendo measures the machine’s vibration patterns and creates a “calibration map” that predicts how the machine will vibrate and calculates how to offset that motion. So, if a machine veers to the left instead of going straight, VC adjusts the path to the right, which cancels out the leftward motion and the machine goes straight.

Ulendo VC-R could enable companies to use smaller, lower-cost robots and cobots for 3D printing. This would enable more manufacturers to use robots for 3D printing and allow users to scale up by adding more robots. Pictured: KraussMaffei is the maker of an enclosed machine for large-scale polymer 3D printing. At Formnext 2024, the company introduced the additional availability of its polymer extrusion technology for use with robot AM systems — more about this on AM Radio. Photo | Additive Manufacturing Media

From 3D Printers to Robots and Back Again

Okwudire explains that robots, in general, pose more of a challenge for vibration compensation than traditional FFF 3D printers. Vibration patterns change based on a machine’s movement and payload. Not only do robots have more freedom of motion than the three axes of a typical FFF machine, but the payload in robotic applications can also change as well. However, plenty of robotics applications involve constant payloads, including 3D printing. Given that the vibration patterns will only vary based on the robot’s position, applications with fixed payloads, such as 3D printing, are good starting points for Ulendo VC-R.

Okwudire says vibration compensation would enable companies to use smaller, lower-cost robots for 3D printing applications. And even if lower-cost robots can’t move significantly faster with vibration compensation, their ability to produce higher-quality prints and lower price points gives users the option to scale up by adding more robots.

“This might help unleash 3D printing with robots,” he adds. “It's still very niche, but I think if you have lower cost robots that can 3D print accurately, then you might just see more people leveraging robots for 3D printing.”

Related Content

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreVideo: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreUlendo and Rev1 Technologies Collaborate on Software Upgrade That Increases Speed of Industrial Extrusion-Based Printers

Formnext 2024: For the CreatBot F430, Rev1 is offering the Ulendo VC vibration compensation software upgrade which is said to quintuple the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreSolving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read More