For Production AM, Is Metal a Better Candidate Than Polymer?

Taking stock of the many AM successes we have covered on The Cool Parts Show, and what the breakdown by material type reveals.

Share

Read Next

Is additive manufacturing a more ready and successful solution for metal part production than it is for plastic part production?

Here is an accounting by material type of all the additively manufactured end-use parts or products we have featured in regular episodes of The Cool Parts Show. (Some regular episodes have been event reports featuring many parts — those are not included here.) The “.5” numbers reflect the fact that one product involved both 3D printed metal and polymer composite. As this accounting shows, our ongoing search for additive parts has uncovered (by a small amount) mostly applications in metal.

The answer is subject to change as AM technologies and their applications continue to advance.

But the answer today is likely yes, and that answer is counterintuitive. 3D printing of plastics has been with us longer and ought to have a head start. But 3D printing might be better suited to answering production needs and winning production applications when metal is the material.

To be sure, there is no way to know this for certain. There is no practical way to conduct a census of AM production applications. However, I have been involved for years in what could be seen as a meaningful survey of AM end-use part applications. We recently celebrated the 5-year birthday of The Cool Parts Show, the video series I co-host with Stephanie Hendrixson about parts and products made via AM. Nearly all the 78 (and counting) regular episodes of this show have been about some distinct and separate end-use application of AM. And as part of a YouTube livestream honoring the show’s anniversary, I took stock of all we had done, including noting the breakdown of “cool parts” by material. I might have expected polymer to dominate this list.

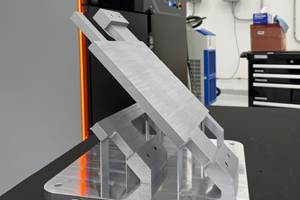

But no. Just over 50% of the applications we have found, applications fully realized enough that we could show the part and develop an episode around it, were in metal. All other materials — polymer, ceramic and composite (including one metal matrix composite) — together account for under 50%.

I might have expected more polymer successes because polymer is the easy entry point for AM. Desktop 3D printers can make production components. Meanwhile, larger and faster industrial polymer AM machines offer production solutions competing against molding at increasingly larger quantities.

But in preparation for that same livestream, I had a conversation that highlighted some of the special challenges of plastic part production. Spencer Loveless has appeared on the show — his company Merit3D provides production services in plastic via digital light processing AM; I called to get an update. One notable job has been a million-piece order for 3D printed parts. Yet Loveless freely admits the success rate at providing an effective solution to plastic part production opportunities is low. In part this is because the denominator is high — he hears from a lot of companies interested in AM. But it’s also due to the state of AM’s limitations. When a polymer job is not right for additive, he says, the reason is generally cost per part or material properties. And as I consider these reasons, I think it becomes easier to see why metal might offer the more natural way forward for AM into production.

Taking them in turn:

1. Cost. True, mold tooling for plastics is costly. AM often succeeds where a manufacturer is not ready for this investment or cannot wait for the mold. Still, the cheapest plastics production process is one in which the mold tool is on-hand and already paid for, and AM has little chance if this is the case. By contrast, metal is inherently more costly to work with even in an established process. Machining, forging, casting — all are high-wear or high-energy processes. AM is nearer to success in metal because the competing cost per part is already higher.

2. Material properties. Manufacturers relying on plastic have grown accustomed to getting (a bit of an exaggeration, but not much) exactly the mix of properties they want. Polymer engineers are chemists realizing a greater range of material freedom than the metallurgists who innovate alloys. In both material types, the range of possibility is greater in established manufacturing processes. But in metal, additive can deliver a larger percentage of the performance combinations manufacturers expect.

There is even more to say about why metal might offer the better AM production case. For example, assembly consolidation is a bigger win when metal parts are involved.

But more importantly, there is more to be written. Any AM cost or material limitation today is a fleeting barrier, because the processes are improving and their material envelopes are growing. We might be in a moment or season for success with metal in production AM. The moment or season for greater successes with polymer might be what comes next.

In fact, maybe we will discover as much whenever we next celebrate a milestone for our show and tabulate AM’s successes at that time. If that is to be the case, you can contribute to the tally. Tell us about your AM success in polymer, metal, composite or any material at coolparts@additivemanufacturing.media.

Related Content

What Does AM Want? Here Are 4 Aims (Maybe 5) That Additive Manufacturing Is Driving Toward

Certain freedoms and contributing factors allow additive manufacturing to realize its full promise for production.

Read MoreAdditive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreA Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreRead Next

The Cool Parts Show Fifth Anniversary Livestream: Watch the Recording

We discuss what the show reveals about the state of AM adoption so far. We share updates about cool parts we have covered. Join us in celebrating 5 years of the show about 3D printing for end-use part production.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More