Aerospace

Will Additive Manufacturing Play a Major Role in Aircraft Production?

One answer: It already does. Lockheed Martin discusses the challenges and promise of producing parts through 3D printing.

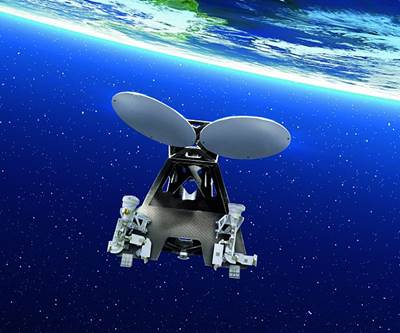

Read MoreSatellite to Use Additive-Manufactured Components Directly Exposed to Space

Support structures are produced through FDM in plastic material as strong as aluminum. Internal complexity is part of the reason for producing the parts through 3D printing.

Read MoreAdditive Manufacturing of Brackets Saves 1 Kilogram per Satellite

Because of complexity, material and quantity, spacecraft and satellite components are good candidates for additive production.

Read MoreNothing But Design Intent

The way to save cost through additive manufacturing is not only to use it to eliminate unnecessary material, but also to apply it within a process that avoids unnecessary effort and interpretation by keeping all manufacturing information within the digital realm. Lockheed Martin is pursuing this ideal.

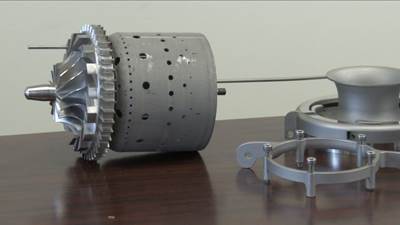

Read MoreVideo: Miniature Jet Engine Made with Additive Manufacturing

GE engineers started with a radio-controlled engine and redesigned it for additive manufacturing. This model manufacturing exercise illustrates important real points about additive manufacturing as a production option.

WatchNumbers Describe Additive Manufacturing’s Advantage

Airbus quantifies the material and energy savings it will realize on parts that are 3D printed.

Read MoreGE Brings Production-Volume Additive Manufacturing to Alabama

Company says the site could ultimately have 50 additive manufacturing machines. Nozzles made here will be shipped to an even newer manufacturing site in Indiana.

Read MoreVideo: World’s Largest Additive Metal Manufacturing Plant

GE Aviation facility in Italy will have capacity for 60 machines making metal production parts through additive manufacturing.

WatchVideo: Additive Manufacturing in Extreme Application

NASA’s test of a rocket engine fuel injector made through selective laser melting illustrates an additively produced part’s capacity to perform at high temperature and pressure.

WatchGE Contest Winner: The Most Strength with the Least Weight

GE recently announced the winner of its Jet Engine Bracket Challenge. The challenge involved a bracket to be shifted from CNC machining to additive manufacturing. Machining limits design options, but additive manufacturing offers complexity for free.

Read More