U.S. Military Officers Cautiously Optimistic On AM for Repair Parts

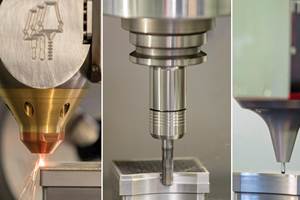

The challenges of worldwide 3D printing by the military include confidence in AM processes and cybersecurity. The rewards of overcoming these will include improved affordability, improved repair capability and greater military readiness.

Article originally appeared in Aviation Week. Used with permission.

Imagine a decade from now, maintainers aboard a U.S. aircraft carrier at sea using additive manufacturing to “print” a moderate repair part for an F-18, allowing the fighter to get back in the air quicker while optimizing military readiness, capability and costs.

Whether that vision becomes reality in just 10 years or longer remains to be seen, current and former military leaders said at the Aviation Week MRO Americas conference held in Dallas on April 5. But this scenario, or others like it, is coming. Unfortunately, it just might feel like a lifetime until it transpires, they suggested.

“If you have an idea of what you think additive manufacturing is going to look like in 10 years, I would tell you your ideas aren’t big enough, your dreams aren’t ripe enough,” said Jim Regenor, director of advanced manufacturing services at Moog Inc. and a retired U.S. Air Force colonel with command and Joint Staff experience.

Just do not expect it anytime soon. “Sometimes the Air Force and the Department of Defense can’t get out of [their] own way when it comes to inserting new technologies—I know that,” said Lt. Gen. Lee K. Levy II, commander of the Air Force Sustainment Center. “We’re very conservative.”

Yet, cautious optimism dominated the military portion of the annual MRO (maintenance, repair and operations) conference, as leaders like Regenor and Levy discussed additive manufacturing, as well as other groundbreaking technologies like digitization, “big data,” analytics, virtual reality and others. Panelists at the conference predicted such technological innovations will be implemented on the commercial side of the MRO industry first, and mainly to help reduce costs and grow profit margins. But they will eventually and naturally be incorporated on the military side, where government customers now care about affordability almost as much as military readiness and capability.

“Keep bringing those ideas, keep banging on the door,” Levy pleaded in his keynote address. There are challenges to adopting such technology in the military, but they can only be overcome by working through them, he said.

For instance, with additive manufacturing, the industry will have to gain more confidence about the material science behind printed materials, including faults and tolerances. Beyond airworthiness standards, military specifications will demand a new category of molecular understanding and documentation. “It has great benefits, great potential, great risks,” Levy said. “It doesn’t have the same maturity or levels of experience, engineering pedigree, in some cases.”

There are also deep concerns about cybersecurity, he and others said, as the promise of worldwide printing entails communication of massive data packs. Also, the end-goal cannot just be printing something once, but in reliable replication countless times. Finally, there will be a slew of training and logistics to work out within the military, as well as numerous legal issues to work out with industry such as how warranties and intellectual property rights work in a 3D world.

Still, there is progress already being made, according to USAF Col. Dennis Dabney, acting deputy assistant defense secretary for maintenance policy and programs. “Currently, there is not a path to airworthiness, but there is a path to getting something flying,” he said.

For instance, the Naval Air Systems Command is pursuing production of flight-critical engine nacelle components for the V-22, with later plans to support the H-1, H-53, F/A-18 and AV-8B. Also, the U.S. Army Research, Development and Engineering Command has the Laser Enhanced Net Shaping (LENS) program for repair processes supporting its M1A1 Abrams, AH-64 Apache, UH-60 Blackhawk and M240 Machine Gun systems.

The V-22 effort could lead to the ability to make a new repair part for the tiltrotor somewhere, for instance. In the latter effort, a high-pressure section shaft on an AGT 1500 engine could go from costing $7,558 apiece and taking more than 20 weeks to provide anew, to just $2,500 and three weeks using a LENS-repaired item.

Added Dabney, “All of the services are using a crawl-walk-run approach to this.”

Related Content

7 Important Ideas on Postprocessing in AM

Additive manufacturing is defined by 3D printing, but it is more than this step. For almost every AM production part, steps after the 3D printing operation are essential to complete the part and realize its value. Here are several thoughts.

Read More5 Points You Might Not Know About Hybrid CNC Machine Tools

Hybrid Manufacturing Technologies’ co-founder describes the role of hybrid additive manufacturing machines, and explores their possibilities related to heat treating, multimaterial tooling and making parts with embedding sensing.

Read MoreVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreWhat Is the Role of Directed Energy Deposition (DED)? We Are Still Discovering It

The applications go well beyond repair. Recently posted articles find many different use cases for DED, including its expanded application for production parts.

Read MoreRead Next

How Do You Make a Howitzer Less Heavy?

Large nuts that used to be solid metal are now grown with a honeycomb structure on the inside for valuable weight savings.

Read MoreMetal 3D Printing in a Machine Shop? Ask the Marines

A hybrid system combining metal 3D printing with machining gives the Marine Corps perhaps its most effective resource yet for obtaining needed hardware in the field. It also offers an extreme version of the experience a machine shop might have in adding metal AM to its capabilities.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More