Share

Read Next

Scroll to unlock this premium content if video does not play.

Aircraft makers applying 3D printing processes to manufacture plane components often begin with less critical parts first, then proceed to more vital parts as confidence builds. But with General Atomics’ introduction of directed energy deposition (DED) to part production, the company began with a part that could not be more critical to flight. DED via the Rapid Plasma Deposition process from Norsk Titanium will be used to 3D print the wing splice for an unmanned aerial system following requirements similar to those of the company’s existing SkyGuardian aircraft. That is, this process will make the part that affixes the wings to a remotely piloted plane. Producing the part this way makes it practical to apply titanium to a component previously machined from aluminum, allowing a more compact design. The Cool Parts Show visited Norsk Titanium in Plattsburgh, New York, where the General Atomics wing splice will be made. | This episode of The Cool Parts Show is sponsored by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- More applications of additive manufacturing at General Atomics

- More on Norsk Titanium and the Rapid Plasma Deposition process

- Other examples of AM enabling unattended vehicles, including the engine for an unmanned aircraft and the hull of an autonomous underwater vehicle

Transcript

Peter Zelinski

We are at Norsk Titanium, Plattsburgh, New York. They use a directed energy deposition additive manufacturing process to make titanium aircraft parts, including parts that are very important to flight, like this one, which holds on the aircraft's wing.

Stephanie Hendrixson

This part used to be made out of aluminum, but now that it's 3D printed, it's made of titanium.

Peter Zelinski

The General Atomics 3D printed wing splice on this episode of The Cool Parts Show.

Stephanie Hendrixson

Today we are coming to you from the Norsk Titanium additive manufacturing production facility in Plattsburgh, New York. Here they have 22 metal 3D printers. Four more are going to come online later this year, and when all that is ready, they expect to have a 700 metric tons of 3D printing capacity when everything is up and running.

Peter Zelinski

Norsk Titanium, company founded in Norway, but they have this part production facility in New York State. They have a proprietary metal deposition process, Rapid Plasma Deposition. And we'll get into that more in the course of this episode. But basically it is a way of 3D printing titanium 6-4 alloy with properties like forging. And most of the customers are in the aircraft industry.

Stephanie Hendrixson

So this is a wing splice for an aircraft produced by General Atomics. It goes on an unmanned aerial vehicle UAV. So think drone, but way bigger. It's basically the size of a small plane. But instead of carrying passengers, it's carrying surveillance equipment or other types of payloads, all without a pilot. UAVs are this interesting application for additive manufacturing, because it allows for 3D printed parts to get onto these vehicles easier without dealing with all of the regulations around passenger aircraft. So General Atomics has taken this idea pretty far. They've incorporated a lot of 3D printed parts onto their aircraft, but this wing splice represents sort of the next evolution.

Peter Zelinski

General Atomics is a leading user of additive manufacturing for production. Its SkyGuardian aircraft has a number of different production components that are made through 3D printing, but for the most part they are non-critical components. The plane could keep flying without them. The next step is to apply additive manufacturing to high value critical components, and this is an example of that. To get us started more about General Atomics how they think about additive manufacturing. Here is Steve Fournier, senior manager for additive manufacturing with General Atomics Aeronautical Systems.

Steve Fournier

We’re primarily an information company. So we collect information, we analyze the information, and we transform that into an intelligence package for our customers to be able to use it. The way we collect that information is through airborne systems. So that's why we became known as an unmanned aerial system company. For General Atomics, additive manufacturing goes back over 12 years, approximately. And where we started our journey, like any other company, I would say, is by exploring that for prototyping, form fits, fixtures and shop aides and things like that, which is a great way to discover the potential for both the materials and the processes. Right around 2015 or 2017 timeframe, there was enough knowledge accumulated across the different stakeholders at the company to really determine whether or not there was viability for more than just prototyping. And this is where the production transition started. On the SkyGuardian, we have over 240 or 245 part numbers that are additively made. So that represents actually less than 1% of the BOM structure, but only with that small proportion we've been able to save hundreds of thousands of dollars of recurring cost for these aircrafts on the component level.

Stephanie Hendrixson

So Steve is also the manager of the Additive Design and Manufacturing Center of Excellence at General Atomics. So part of his role is to be looking at these vehicles that are being developed and looking for opportunities for 3D printing. Those 240 or 245 3D printed parts that are already on the SkyGuardian represent a whole range of different 3D printing technologies, different materials and different levels of criticality. Many of them are things like air intakes, manifolds, covers and closures, parts where a failure would not necessarily be catastrophic to the aircraft. This wing splice is obviously a very critical part, but General Atomics decided that it was worth pursuing additive because of the material choice here.

Peter Zelinski

So yeah, the aircraft has a structure, it has a skeleton. And, for the most part, these structural components are made from aluminum. It is a relatively easy metal to work with. Aluminum works. But the thing about additive manufacturing is it introduces a practical way to make many of these parts out of titanium, and that is a win. So to set the context for understanding that, here is Steve to talk more about criticality, how aircraft part producers, how General Atomics in particular thinks about the different criticality levels of different components.

Steve Fournier

You typically have four levels, class A, class B, class C and class D parts. And the more you get towards the A class, the more critical is your parts. In relation to DED, especially from a DED titanium for us, the trend for our use of titanium is typically a class A part, class B, sometimes, but we use titanium for its strength to mass ratio. Usually you can think about high strain aluminum hat will be a much easier material and much cheaper material to use. The drawback of using aluminum sometimes is that you need to bring margins of safety, as part of your design, which, makes the part less mass effective.

Peter Zelinski

So aluminum worked. The existing wing splice currently on the SkyGuardian, it's made of aluminum, but to get a sufficient safety margin from an aluminum part, the part had to be bulkier than this. Titanium is a stronger metal, and it introduces the chance to create a wing splice that offers the same performance, but in a more compact form, a part that takes up less volume on the aircraft. It's just that titanium is a harder metal to work with, a harder metal to machine. Additive manufacturing, this deposition process, offers the chance to get a nearer net shape form to minimize the amount of machining. So the result is, the chance to replace aluminum structural components with titanium components that offer the same functionality. Here's more context about titanium.

Steve Fournier

The amount of material you start with, the cost of the raw material, titanium, and the cost of machining and the labor associated with it is where, you know, you're gaining on the matter there. So from a machined titanium to a DED titanium, there is a cost effectiveness there. And what we need to start talking about is the total cost of manufacturing of a part. Not so much just the printing or the raw material.

Stephanie Hendrixson

So in other parts where we've seen 3D printed titanium being used, it's often a choice for lightweighting. And that's actually more of a side effect here. For this wing splice, switching from aluminum to titanium is actually more about reducing the bulk, reducing the cost of the component. And 3D printing is the manufacturing method that makes titanium accessible enough to do that. So let's learn more about the method that is used to make these wing splices. Rapid Plasma Deposition. Here is Steve Schuster. He is the director of production engineering here at Norsk Titanium.

Steve Schuster

Norsk Titanium makes parts for commercial aerospace, industrial and defense. We have developed around the additive machines. Our material has forging equivalent properties directly from the machine. Rapid Plasma Deposition is a wire arc DED process, which makes use of dual plasma torches and a rapid cooling technique, to produce forging quality components. We can produce high quality product with fully dense material and forging equivalent properties. Our ability to preheat previous layers while depositing allows us to produce some of the most consistent material properties in the industry. We use this technology to additively manufacture Ti64 components in that industry, and we are actively displacing legacy hog-outs and forgings today. Aerospace by a long shot, has the highest demand for Ti64 products. The majority of the world's Ti64 demand is in the Airbus A350 and the Boeing 787 aircraft. Commercial aerospace has some of the strictest standards. We decided if we could successfully produced in aerospace, we would be well positioned to produce in any other market.

Peter Zelinski

So it was that qualification, that experience with aircraft part production that drew General Atomics. So directed energy deposition, DED in general refers to 3D printing by depositing metal. Norsk Titanium’s Rapid Plasma Deposition is a more sophisticated DED process that involves process controls, including very controlled heating and cooling of the material to, among other things, eliminate the need for downstream steps like hot isostatic pressing or HIPing. So the result is this very productive additive manufacturing process that delivers repeatable properties in titanium 6-4 that is suitable for aircraft part production.

Steve Schuster

In the right application, we can reduce the buy-to-fly ratio of a design to two and a half to three and a half to one. This means the customer will only buy about three times as much material as the final design to machine from. Some aerospace parts can have 20 to 1 or higher buy-to-fly rates using legacy processes. This additional material and processing cost is significant due to the difficulty of machining Ti64 material. If you were hogging it out of block, it is typical to see 90% wasted material converted into chips. It saves energy and is a greener alternative to conventional processes. In comparison to forging, our cost is generally on par with the forging. But the time to develop RPD shapes is significantly shortened. The RPD process is also flexible and allows for quick changes to the shape.

Peter Zelinski

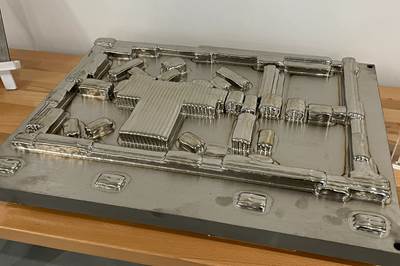

Buy-to-fly, that phrase captures what is so significant about getting to use a metal deposition process in titanium to make a part like this. That phrase refers to how much metal does the aircraft producer have to buy versus how much actually ends up flying in the form of a finished part on the plane and in the aircraft industry, buy-to-fly ratios can be way out of kilter. It is very common for most of the mass of a metal block to be machined away, to realize the final slender form of the aircraft part required. So in the absence of 3D printing, how would a part like this be made? Forging is one alternative. Forging can also deliver a near net shape part, not necessarily as near to net shape as this, but closer. The problem is, forging requires a significant upfront tooling investment probably too much of an investment to be justified by the production quantity needed of this part. So that would leave machining a part like this entirely out of a block of solid titanium. Set aside the difficulty of that. Titanium is a difficult material to machine, in addition to all of the energy, all of the work of machining away all that material, there's all of the material that is wasted that is not used because it's milled away as chips to realize this form. Additive manufacturing can eliminate this waste. Norsk Titanium’s RPD process can deliver a preform like this, a part that is a starting point for machining that is much closer to the final shape of the part.

Stephanie Hendrixson

So closer to net shape because as you can tell from the parts that we have in front of us, the 3D printed preform and the final wings splice. There is still machining that has to happen, but it is much less when you start with this 3D printed form. That means you're buying less material and you're wasting less material. The buy-to-fly ratio becomes a lot more favorable. And now Norsk is at a point where they are experimenting with the tweaks they can do to improve the manufacturing process.

Steve Fournier

In terms of the RPD process and it's probably true for pretty much any DED process from our experience, depending on the application, you'll have to tweak the toolpath generation strategy to ultimately lower your buy to fly ratio. Right. It's all about buy to fly ratio for us, at least for those application, because they have to be fully machined at the end of the day. We don't have the luxury to leave the part as printed. What that means is that the least amount of material I have to post machine, the better it is for us from a raw material preform of the RPD all the way up to the time of machining and the cost of doing that. The toolpath optimization is critical, and that's what we've learned, among other things, but it's critical for two things. One is the amount of materials you'll have to remove. So if you go really conservative you're going to build yourself a nice block. but that's then you're defeating the purpose, right? So you want to have a preform as close to your final form as possible to gain on the buy-to-fly ratio. The second piece is the toolpath will be the driving force for quality. So you don't want to have inclusions. You need to meet some specific specs. The AMS specs that are standards for this process. You need to meet those specs. To do that, you need to have a stable and repeatable and optimized toolpath. And that's very application specific. That's what, for the most part, led us to Norsk Titanium because they've done so much investment internally and also have experience in the past with other customers that really showed us that all those process variables are well understood, and especially when it comes to the toolpath generation, they have a team that really understands and can simulate their toolpath in order to lower our NRE in the iterative process that typically comes together with DED technology.

Peter Zelinski

We should observe, this part is challenging even for Norsk Titanium. We are in this Rapid Plasma Deposition factory. These machines behind us do nothing but make production parts using the RPD process. This part has distinctive geometry that makes it a little challenging.

Steve Schuster

It has a large loop around one side of the preform and two independent curved wall configurations on the opposing side. this loop alone is the largest continuous deposition Norsk Titanium has produced to date., measuring over seven feet long. This component was developed within our Itar compliant Secure Data Enclave facility using a US persons development team and our RPD builder software. This project required technology development from the Norwegian team, resulting in a significant improvement to our curved deposition capability. Expanding the range of geometries RPD is capable of producing further. Due to the speed at which we can deposit material a component of this scale can be completed within one day of production across two shifts.

Stephanie Hendrixson

So this 3D printed wings splice is not in production yet, but because of the development work that Norsk Titanium has already done on optimizing those tool paths and other parts of the manufacturing process, Steve Schuster says that just one of these RPD machines could handle the serial production of this component.

Peter Zelinski

And General Atomics is going to get there. Five of these wing splices have been made so far. The production process is proven, but as we've said, this is a particularly critical component of the aircraft. The next step is flight testing, extensive flight testing to validate that this part will do everything expected in the air on an actual aircraft. In the meantime, some of the lessons learned from making this part are being applied to other structural components of the aircraft.

Steve Fournier

If you look at what constitutes a good candidate for titanium on aircrafts, of course, you've got lots of aluminum and that's our default. But as I said, I see the future being, going towards converting some of the aluminum components into titanium, when the cost makes sense and there's a good margins benefit. So I can see application space that we don't see today on titanium being developed over the next few years. On the titanium to titanium kind of application that we, we can see now, obviously, there are the structural components on the wing structures, some are related to landing gear type of part families, if you will. There are some propulsion group components that also calls for titanium components. So you know, wings, tails, propulsion, landing gear, those are kind of where titanium fits in typically for the enhanced properties of titanium, especially on the margin side.

Stephanie Hendrixson

All right. I think we got this.

Peter Zelinski

This is the General Atomics wing splice. It attaches the wing to the aircraft. Currently, this part is made of aluminum. This version, a future version of the wing splice, is made of 3D printed titanium.

Stephanie Hendrixson

Norsk Titanium is 3D printing. These wing splices here using Rapid Plasma Deposition, allowing for a change in material. Changing the material from aluminum to titanium is allowing General Atomics to reduce some of the bulk of this part, and also to reduce the waste and the scrap and the expense of producing it.

Peter Zelinski

The part is currently undergoing flight testing as a final step to validate it. And in the meantime, other structural components of the same aircraft are being reconsidered, redesigned for replacing aluminum parts with 3D printed titanium parts that are more compact and likely less expensive, as well.

Related Content

The Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read MoreQuadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreAdditive Manufacturing for Defense: Targeting Qualification

Targeting qualification in additive manufacturing for the defense industry means ensuring repeatability as well as reliability as there is much at stake, including human lives. Certain requirements therefore must be met by weapons systems used by the defense industry.

Read MoreFor Coast Guard, AM Adoption Begins With “MacGyver-ish” Crew Members Who Are Using 3D Printing Already

AM suits the Coast Guard’s culture of shipboard problem-solving, says Surface Fleet AM lead. Here is how 3D printers on ships promise to deliver not just substantial cost savings but also an aid to crew capabilities and morale.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More