Aerospace

How Would You Make This Bracket Better?

When design constraints are taken away, what does the very best design for a given application look like?

Read MoreOptimizing Mass and Material

Most machined parts have more material than necessary. This is true even after all of the cutting is finished.

Read MoreThe Meaning of the Morris Technologies Acquisition: An Interview with GE Aviation

Located in the Cincinnati area near GE Aviation’s Evendale, Ohio, headquarters is a leading supplier of contract additive manufacturing services—Morris Technologies. To secure this company’s capacity for its own use, GE Aviation acquired Morris Technologies and sister company Rapid Quality Manufacturing (RQM).

Read MoreGE Aviation Acquires Morris Technologies

Aircraft engine maker GE Aviation has acquired the assets of Morris Technologies and a related company, Rapid Quality Manufacturing.

Read MoreThe Future of Manufacturing

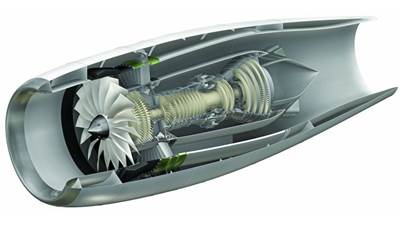

According to engineers with GE Aviation, the challenges of additive metal manufacturing—serious as they are—are small compared to the promise that this technology holds. How else can you make a plane engine 1,000 pounds lighter?

Read MoreElectron Beam Direct Manufacturing As an Alternative to Forging

Lockheed Martin expects to reduce titanium part-production costs for the F-35 fighter by applying this additive manufacturing technology in place of forging.

Read MoreThe Aircraft Imperative

Reduce cost, reduce weight—to the extent that additive manufacturing can do these things, it represents a promising method for making aircraft parts. While important constraints currently prevent additive manufacturing from seeing more widespread use in aircraft production, these constraints might not be what you think. Here is a look at additive manufacturing within Boeing.

Read MoreManufacturing in Space

An additive manufacturing process was recently tested in zero-gravity conditions in an effort to develop solutions for manufacturing in outer space. One thing about additive processes—they don’t create loose chips!

Read MoreAmerimold Workshop: Direct Metal Laser Sintering

Laser sintering is an additive process that deposited metals, such as Titanium, to create complex machinable workpiece blanks.

Read MoreShop Controls Its Own Destiny

Waiting sometimes 12 weeks for delivery of aluminum castings was a production bottleneck for this Colorado aerospace component manufacturer. Using a novel combination of solids modeling software, verification and stereolithography, the company managed to reduce lead times by 25 percent. This approach may be one your shop can use as well.

Read More