Slideshow: Inside the New Honeywell AM Facility for Reactive Metals

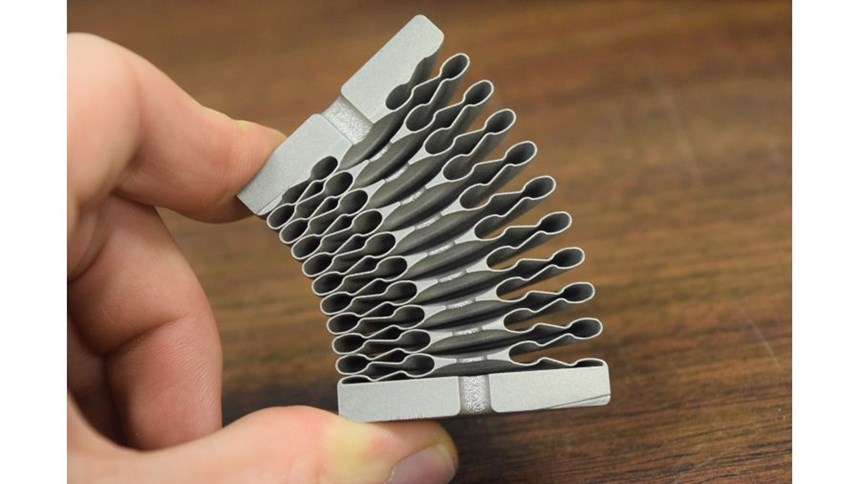

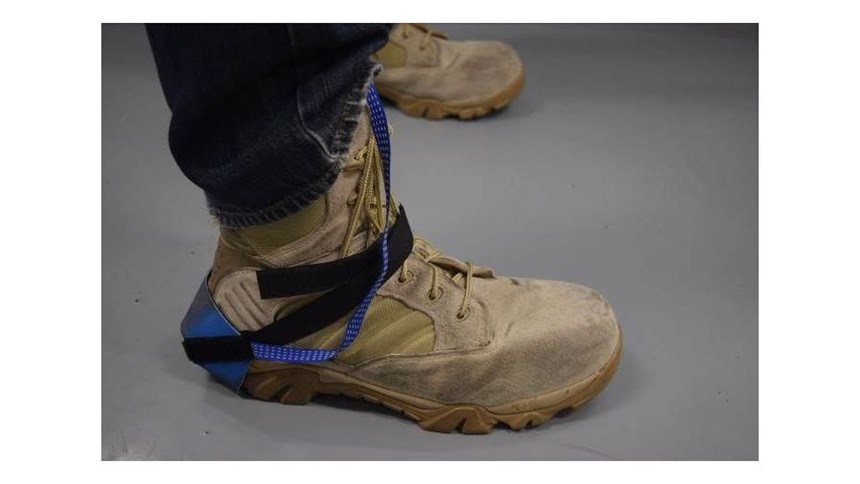

Seven machines currently committed to aluminum expand the company’s capacity to 3D print both tooling and parts. One of the photos illustrates a safety measure addressing reactive metals.

As reported in this article in the Phoenix Business Journal, Honeywell Aerospace has opened a new facility as part of its Phoenix Additive Manufacturing Technology Center that is devoted to reactive metals. At present, the new facility’s capacity is committed to aluminum, but it was recently approved for titanium-aluminum alloys as well.

Honeywell says this is the first AM facility in North America with this focus. Company engineering fellow Donald Godfrey leads the site. He expects the seven metal additive machines here will pay for themselves through the savings and speed resulting from the company’s now-increased capacity to grow aluminum parts and tooling in-house.

The article also reports that further investment in AM is coming. Honeywell plans a 30,000-square-foot facility for production additive manufacturing that will have another 10 to 16 machines.

Use the “Next Image” button above to view images from inside the new facility.

Related Content

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

-

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.