Additive Manufactured Components Reach Jupiter

The Juno spacecraft includes titanium waveguide brackets made through AM.

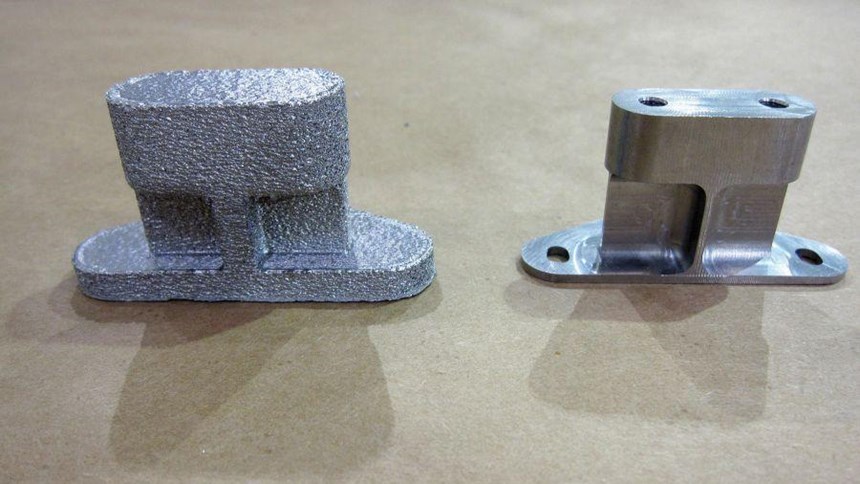

(From 2016) The Juno spacecraft that arrived in orbit around Jupiter on July 4 has now carried additive manufacturing farther than it has ever gone before. Among the spacecraft’s parts are components produced through electron beam melting, including the waveguide bracket seen in the photo sequence above.

Lockheed Martin Space Systems manufactured this part when it had just begun to use EBM. Read about the company’s work in AM in this article and this one.

Related Content

-

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

-

Additive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.