Latest Valves Articles

VIEW ALL8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

WatchValve Manufacturer Outlines Path to Qualification for Additive Manufactured Pressure Equipment

In this case study, Samson shares how manufacturers can design and produce pressure equipment using additive manufacturing that is compliant with the European Pressure Equipment Directive (PED).

Read MoreA Path to Qualification for Pressure Equipment

Can additively manufactured parts be qualified without a direct standard? In this case study, valve manufacturer Samson lays out an approach for qualifying AM parts to Europe’s Pressure Equipment Directive (PED) based on a Particular Material Appraisal (PMA).

Read MoreReducing Valve Cavitation with AM

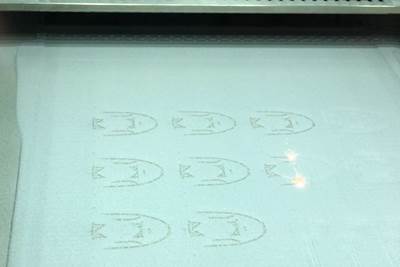

Two different valve equipment manufacturers are finding success with 3D printed products designed to mitigate cavitation, in which vapor bubbles form and burst, potentially causing damage. Designs enabled by laser powder bed fusion counter this downstream effect.

Read MoreReplique Enhances 3D Printing Material Hub, Expands Production Network With Traditional Technologies

Formnext 2024: Replique has also collaborated with several health care providers to develop 3D printed innovations such as a fully 3D printed containment valve and new rollator with a 3D printed frame.

Read MoreShorter Supply Chains, Reduced Cavitation

Baker Hughes has replaced its assembled trim stacks for industrial valves with 3D printed versions that can be built all as one piece. The devices counter cavitation to protect the valves, and the change in manufacturing method has enabled the company to bring most of this production in-house.

Read MoreLatest Valves News And Updates

Featured Posts

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

WatchVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

WatchFaster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read MoreFeatured Media

3D Printed Valve Part Protects Pipes by Preventing Cavitation: The Cool Parts Show #56

The Fisher Cavitrol Hex trim from Emerson divides the fluid flow into numerous parallel streams thanks to geometry made possible through additive manufacturing.

Watch