3D-Printed Medical Drills Keep Bone Cool During Surgery

Drills made via additive manufacturing cut bones without causing thermal-induced damage thanks to internal cooling channels.

The medical profession has, with certain exceptions, tended to adapt commercially available instruments that have been developed for drilling other materials. A drill bit consists of a shank which is used to couple the piece to the chuck of the surgical hand-piece, and flutes which channel bone chips and debris (swarf) away from the machining face and cutting edges.

The operational environment for a surgical drill bit, however, is unique and very unlike that experienced by engineering drill bits used in manufacturing, or traditional nonbiological engineering such as the construction industry. Bone is a complex anisotropic, porous and viscoelastic composite that is also nonhomogenous, both in material properties as well as geometry. Cortical bone is a relatively poor conductor of heat, which is caused by drilling during surgeries due to the shear deformation of bone, friction between the bone chip and the rake face as well as friction between cutting edge and underlying bone. It has been estimated that approximately 60 percent of the heat energy generated during drilling is dissipated by bone chips, which is substantially less than the 80 percent predicted to be removed by the chips during drilling of metals.

As a result, temperatures can rise above 50°C, which can result in the necrosis (death) of the bone, a phenomenon termed osteonecrosis. The magnitude of this temperature rise is determined by a number of factors, including drill geometry and diameter, rotational speed, feed-rate, axial thrust force, initial drill bit temperature, and internal or external cooling. To keep the temperature low, surgery is usually performed iteratively; i.e. the drilling process is repeatedly interrupted in order to keep the temperature as low as possible.

Cooling the drill would be the better alternative, and closed-loop and open internal cooling systems are available but are primarily limited to orthodontic and dental applications. Since cooling the tool may cause fluid to enter the wound, conventional tools with a cooling system are usually avoided.

Creating Internal Cooling Channels

In an effort to develop surgical drills capable of cutting bone without causing thermal-induced osteonecrosis, the Institute of Production Engineering and Machine Tools (IFW) at the Leibniz Universität Hannover, Germany turned to Toolcraft, a manufacturer of precision parts, assemblies, molds and injection-molded parts.

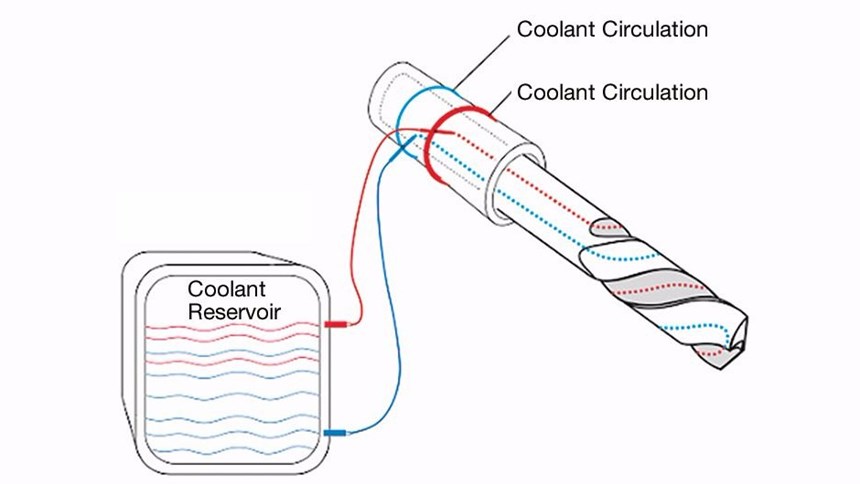

Toolcraft suggested creating internal cooling channels through metal laser melting to allow the coolant to flow inside the tool—along the helix and back to the toolholder—without entering the wound. Although chances of breakage are slim, the drill bit is reportedly the most frequently broken surgical instrument and the possibility cannot be ruled out. According to the company, using water as coolant ensures no injuries are caused in case of tool breakage.

Toolcraft also developed a nonrotating pre-spindle attachment with an inflow and outflow function for the coolant. A continuous supply of coolant is ensured by the attached coolant tank and pump, the company explains.

The internally-cooled prototype was modelled on a conventional bone drill with a diameter of 6 mm. Surgical twist drill bits are available in a wide variety of configurations and sizes, with diameters typically ranging from 0.5 mm to several millimeters. According to Toolcraft, diameters from 5 mm are currently possible to produce using laser melting technology.

Toolcraft and the IFW decided to keep the drill’s geometry to make it easier for users to adapt to the new tool. The internal circular cooling channels with a diameter of 1.2 mm take the thermal energy away from the cutting edge, while flow and return pipes ensure a continuous flow of coolant. bHorizontal drilled holes were added which link the cooling circuit to the drill for the coolant supply and removal. To attach the manifold there is a groove for a circlip.

At the outset of the project, the engineers calculated the cooling capacity in terms of volumetric flow rate, temperature and thermal capacity of the coolant. The project team then developed a method for bringing a closed cooling circuit into the tool substrate while maintaining tool stability and ensuring that the tool was suitable for performing the required processes.

The drill is made of the biocompatible material 1.4404, a corrosion-resistant, austenitic stainless steel (ASTM 316/ 316L). The shape of the drill and the internal cooling channels were designed by Toolcraft using SolidWorks, and the simulation was done by Schmidt WFT in Nuremberg, Germany, using Siemens NX software.

Using an M2 cusing multi-laser machine from Concept Laser, the drill bit including the internal cooling channels was additively manufactured, followed by grinding. To create good chip clearance, the required surface quality as well as sharp cutting edges, the main and secondary cutting edges were ground on a centerless cylindrical grinding machine.

Tests Show a Decrease in Temperature of Up To 70 Percent

Using a drill with a diameter of 6 mm and water as coolant, the IFW performed a diverse range of drilling tests and measured the process temperature in artificial and bovine bone. In doing so, they measured reference temperatures at higher and lower feed rates, with the cooling system turned on and off. Experience has shown that increasing feed rates decrease the maximum temperature when drilling bones.

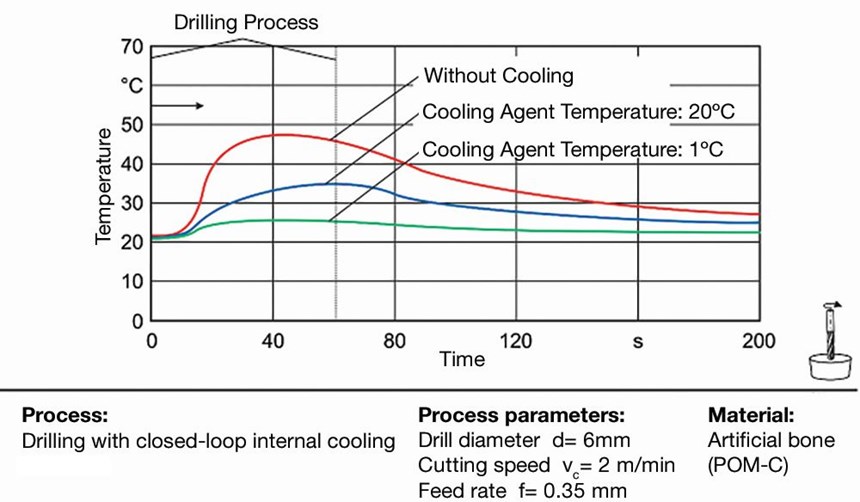

At a high feed rate of 0.35 mm/rev (0.014 ipr) and a cutting speed of 2 m/min. (78.7 ipm) on an artificial bone made of Nylacast Polyactal (POM-C), an engineered plastic, the tests show that the new drill significantly reduces the temperature produced. While the drill without cooling did not exceed the critical temperature of 50°C (122°F) due to the high feed rate, the use of internal cooling kept the temperature at maximum 35°C (95°F) with a cooling agent temperature of 20°C (68°F) and at maximum 25°C (77°F) with a cooling agent temperature of 1°C (33.8°F) (see Figure 3.).

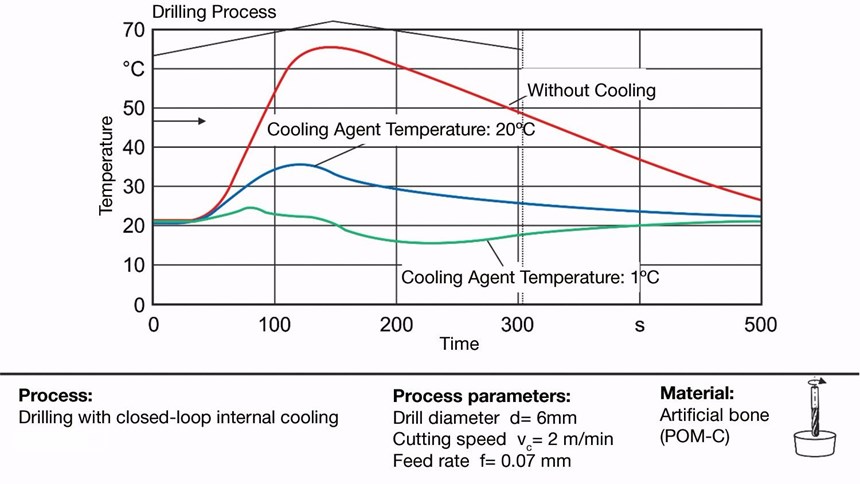

When the feed rate is decreased to 0.07 mm/rev (0.0028 ipr), the test showed the same results for the internally cooled drill, but caused temperatures to rise above 50°C (122°F) in less than 100 seconds for the conventional drill. (See Figure 4.)

Thanks to the ability of the internal cooling system to compensate for increases in temperature, low feed rates no longer lead to higher temperatures, and the risk of excessively high process temperatures which put bones at risk of damage is eliminated. This means that the technology could also be beneficial in a wide variety of other areas, such as the manufacture of saws, Toolcraft says.

Related Content

Durable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read MoreCranial Implant 3D Printed From Hydroxyapatite Ceramic: The Cool Parts Show #76

Cranial implants are typically made from titanium or PEEK; in this episode of The Cool Parts Show, we look at how implants made from a bioceramic can improve osseointegration and healing.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreRead Next

3D-Printed Metal Device Makes ACL Knee Surgery More Accurate

Additive manufacturing made it possible to produce a medical tool that offers surgeons better control during ACL repair or replacement surgery.

Read More3D Printed Hips Versus the World's Deadliest Mountain

3D printed trabecular titanium hip implants—printed by Lima Corporate on Arcam EBM machines—helped legendary Italian mountaineer Romano Benet to continue scaling the world's most dangerous peaks.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More