Aerospace Project Pairs 3D Printing with Investment Casting

A research project conducted by Autodesk reduced the weight of an airplane seat frame using 3D-printed patterns and investment casting in magnesium.

Additive manufacturing (AM) is a natural pairing for design optimization, enhancing the ability to build high-performance parts. However, the size limitations and cost of metal 3D printing can make it less than ideal as the production technology for these parts. A recent project undertaken by Autodesk leveraged the advantages of AM in redesigning an airplane seat, but paired it with a traditional manufacturing method: investment casting.

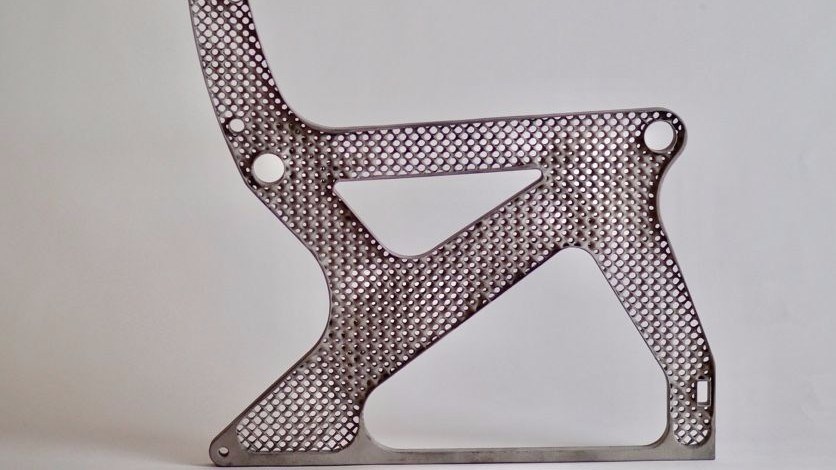

The goal of the project was to produce an airplane seat frame that would be lighter than the original design but just as strong. With Autodesk’s Netfabb software, research scientist Andreas Bastian created a lightweight seat frame design with an organic-like lattice structure, to be manufactured in aluminum.

This design could have been produced with metal 3D printing, but the cost of this process combined with the part’s size led researchers to look elsewhere for a manufacturing method, eventually landing on investment casting. Like 3D printing, investment casting enables complex geometries that wouldn’t be practical to machine or manufacture with other methods. This is possible not through building parts layer-by-layer, but by casting parts in single-use molds that are destroyed in order to remove the parts.

Investment casting offers expanded material options over AM, and better economics at scale. It also has the advantage of maturity. Whereas additive manufacturing is relatively new, casting is well-understood and widespread engineering expertise exists.

For the investment casting process, Autodesk worked with Aristo Cast, a foundry located in Michigan. At the foundry’s suggestion, Autodesk changed the material for the plane seat from the typical aluminum to magnesium for additional weight savings. Using Netfabb software, researchers ran the simulations for the part in the new metal and confirmed its properties.

Though not used as the manufacturing technology, 3D printing did play a role in creating the casting patterns. The Aristo Cast team used the updated 3D model to 3D print positive molds of the lightweighted seat frame in plastic resin. These patterns were then coated with ceramic to create a negative mold. Once the ceramic shell hardened, the plastic was heated and vaporized away, and the mold was ready to be used for casting.

At 766 grams, the resulting cast magnesium plane seats are 56 percent lighter than conventional aluminum seats weighing 1,672 grams. Design optimization accounts for 30 percent of the weight reduction, while the magnesium material makes up the remaining 24 percent. Though this project only produced small quantities of seats, researchers say it proved to be a viable process that could scale up to 160 seats every two days. Autodesk estimates replacing the traditional seats with the magnesium ones could result in significant jet fuel savings and a reduction in CO2 emissions from planes.

The seat frames remain a research project for now, but Autodesk says it was successful in demonstrating the power of combining Autodesk’s generative design capabilities and 3D printing technology with casting. In addition to aerospace applications, the same combination could be used in automotive, medical devices, industrial equipment and other applications.

Related Content

-

Video: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

-

Additive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

.jpg;width=70;height=70;mode=crop)