Additive Manufacturing at EMO 2017

Here are some of the AM technologies Editor-in-Chief Peter Zelinski saw at the world’s largest metalworking show.

EMO is the world’s largest metalworking tradeshow. The show is held every odd-numbered year, most recently last month in Hannover, Germany. And this year, additive manufacturing was both hard and easy to find at the show.

It was hard to find because the show is enormous, consisting of 2,200 exhibitors covering 152,000 square meters of exhibit space within 16 separate halls spread across the Hannover fairgrounds. Additive had its own hall at the show, but it shared that space with other technologies because there are not yet enough additive exhibitors to completely command the space.

Then again, additive was also easy to find at the show. In addition to companies supplying additive technology as their core focus, so many other exhibitors supported, provided or actively employed additive as part of their offerings that it seemed I kept on stumbling upon examples of AM advancing.

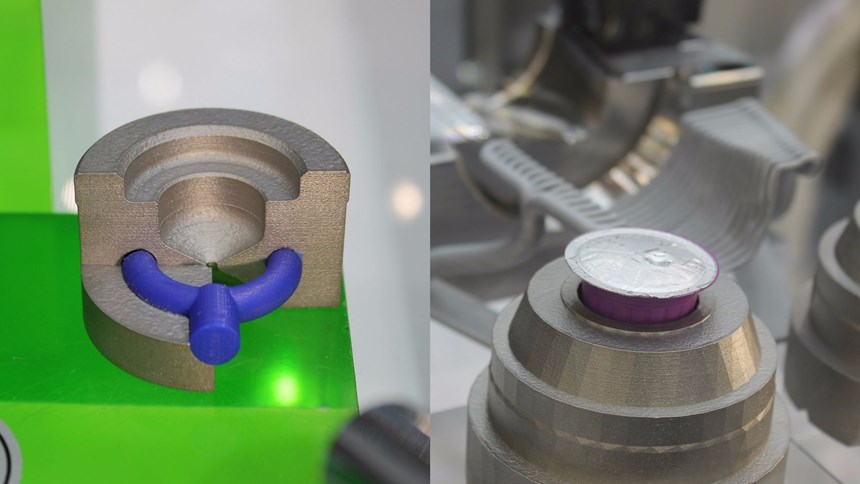

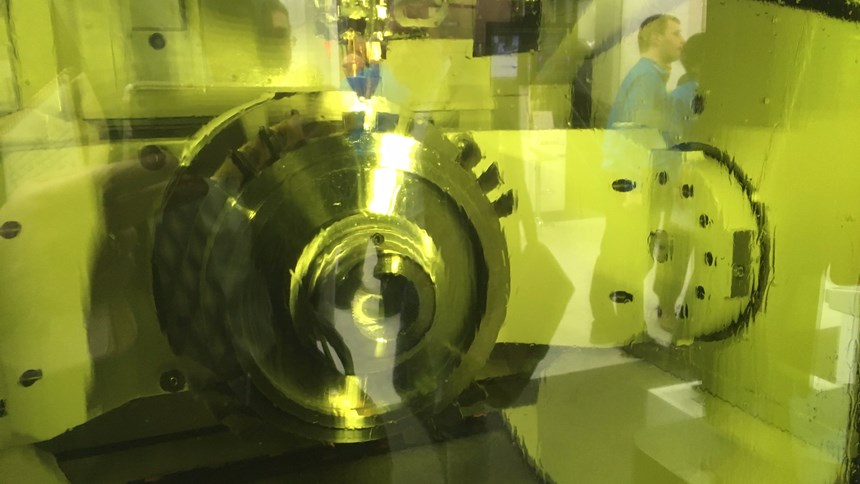

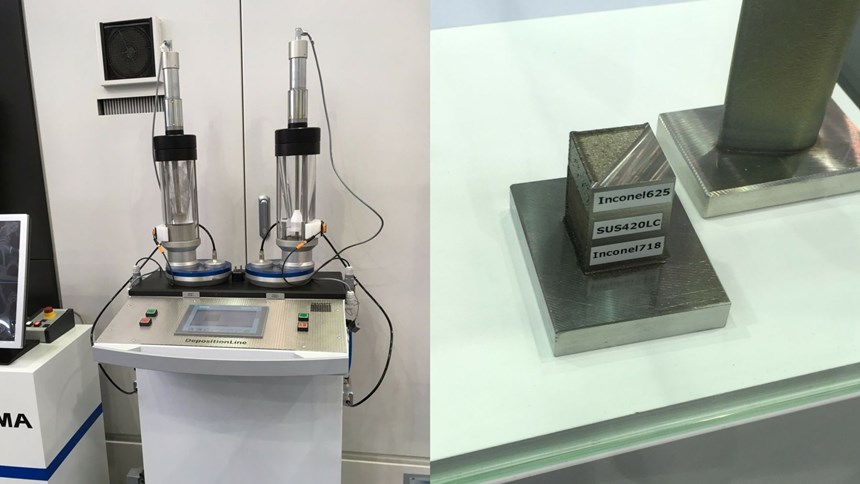

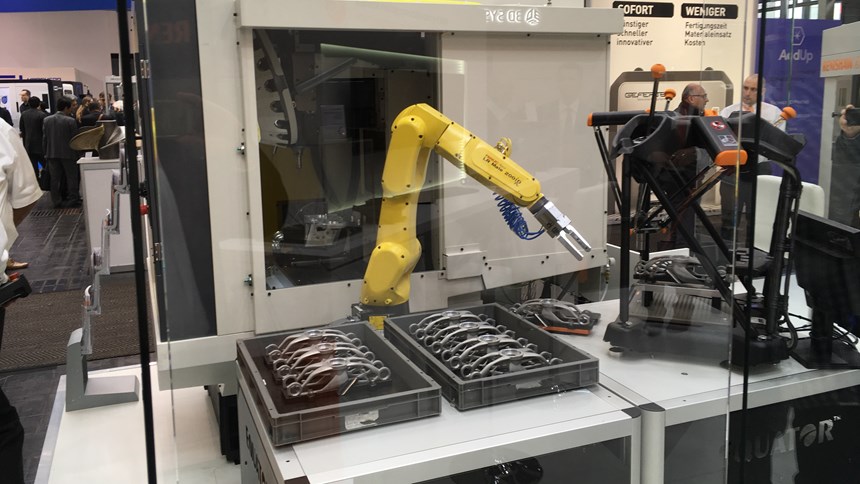

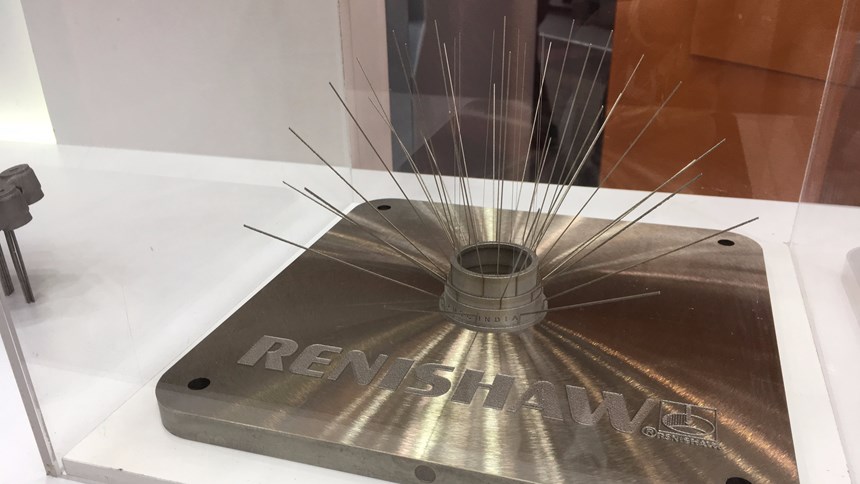

The photos above offer a sample—some of the additive manufacturing technologies and applications found at EMO this year.

Related Content

-

This 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

-

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

-

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.