Installing a Metal 3D Printer, Part 3: Safety Risks

PADT’s third blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks and ways to mitigate them.

What Safety Risks are Involved in Metal 3D Printing?

This is the third post in a series of five on things we learned from installing a metal 3D printer (laser powder bed fusion).

The most important discussions around installing and operating a metal 3D printer involve safety. The requirements can be difficult to pin down since they depend on several things: whether you are using reactive or non-reactive alloys, the risk perception of your local building safety director and fire marshal, local regulations (and exceptions), and the volume of material you are dealing with. As with all things safety—and more so because of how nascent metal 3D printing technology is—I list a few disclaimers at the bottom of this page.

There is so much to say about safety in this process that, halfway through writing this, it became clear it would not fit in one post. Therefore, I have split the content into two: in this post, I talk about the risks—where they come from and why they matter. In the next post, I will discuss how these risks can be mitigated.

Sources of Risk

Broadly speaking, I like to think of two sources of risk in this process since as an operator of these machines you have to think differently about how you interact with these sources.

1. Metal Powder

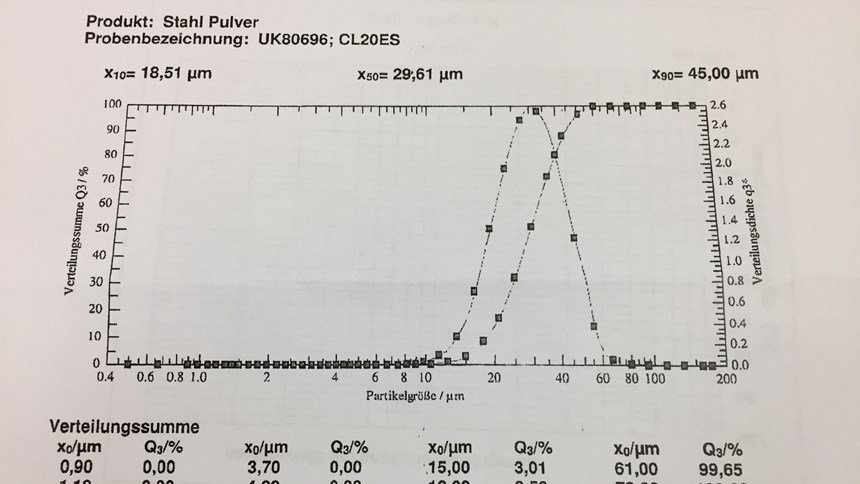

Metal 3D printing involves fusing together powder in a bed. Typical metal powders used for laser-based 3D printing are spherical in shape and range from 10 to 70 microns in diameter, as shown in Figure 2. At this size and under the right circumstances, a metal can be prone to fire and explosion, and there is also the physiological concern of long-term inhalation of, and contact with, these powders. The powder also has a long life cycle and requires human interaction at many steps—from arriving in a container (as shown in Figure 3), through multiple recycling steps, through final disposal. While these risks come into play just when handling the powder (independent of its use in the process), an additional risk comes from the melting process itself.

2. The Laser Fusion Process

The powder in the bed described above is fused together into a solid using a laser that locally melts the powder one layer at a time. This is conducted in an inert atmosphere (argon or nitrogen) and is the second source of risk since these gases can displace oxygen from a closed environment. Additionally, the process of laser melting of metals creates vaporized soot (see video below), some of which deposits on the process chamber and in the extraction module and filter. The smoke particles can be even finer than the powder itself and need to be cleaned out with care on a regular basis.

Risks

There are four main risks that arise from the laser powder-bed fusion process: fire and explosion, powder inhalation and contact, inert gas asphyxiation and the environmental impact of the wastes generated.

1. Fire and Explosion

In May 2014, OSHA cited a 3D printing company for 10 violations deriving from the workplace safety standards surrounding the operation of a metal 3D printer (including not having the proper Class D fire extinguisher). The disregard of multiple safety measures during a routine build setup procedure resulted in a fire which caused life-threatening burns to the operator of the printer. While this incident was the result of negligence, it is nonetheless a cautionary tale that should drive us to understand the fundamental reasons why a metal 3D printer can cause fires and to appreciate the underlying reasons for why suppliers recommend the safety measures they do.

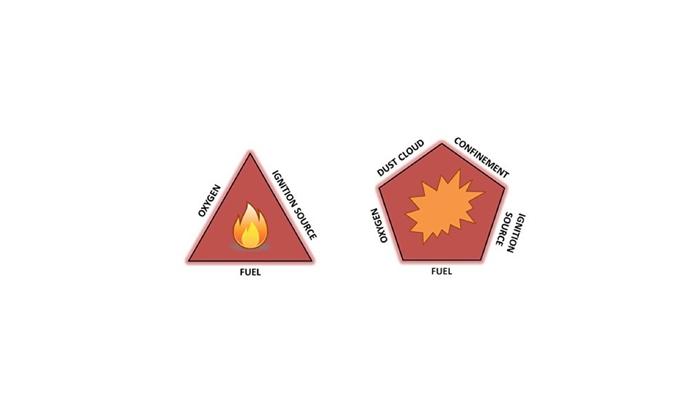

Fire and explosion require a combination of conditions as shown in the commonly cited image below used by OSHA and other agencies to communicate risks of powder handling.

As shown in Figure 1, when handling powder in ambient atmospheres (with oxygen), all that is needed is a suitable ignition source to initiate a fire. Further, if this occurs in the presence of a dust cloud with many particles dispersed in a contained area (such as a small room or an air duct), this could lead to a more damaging explosion.

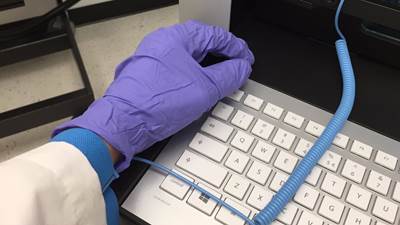

- Fire: When handling metal powder, the user needs to be aware that she/he already has met two of the three requirements for a fire, and the main aim must be to ensure protection against any ignition source. While there are several sources that could cause an ignition, the most likely source for a user of a metal 3D printer is static electricity. Additionally, it is possible that a fire can be initiated by hot surfaces, flames, hot gases and particles, mechanically generated sparks, and stray electrical currents.

- Explosion: With regard to explosions, in addition to the three requirements above, dust clouds in contained areas can exacerbate any ignition to a much larger impact within milliseconds. Therefore, the prevention of the formation of metal dust clouds, as unlikely as that may seem, is of paramount importance.

In addition to the requirements above, there are levels associated with each requirement that need to be met together for an actual fire or explosion to occur. While the risk of ignition increases with reducing particle diameter, given certain particle size, the most significant factor governing risk is the nature of the metal. Reactive metals (aluminum alloys, titanium and its alloys, as well as smoke particles from both reactive and non-reactive) pose much higher risk than non-reactive metals (steels, Inconel, bronze, cobalt-chrome alloys). This is a subject I wrote about in more detail in a different blog post.

2. Powder Inhalation & Contact

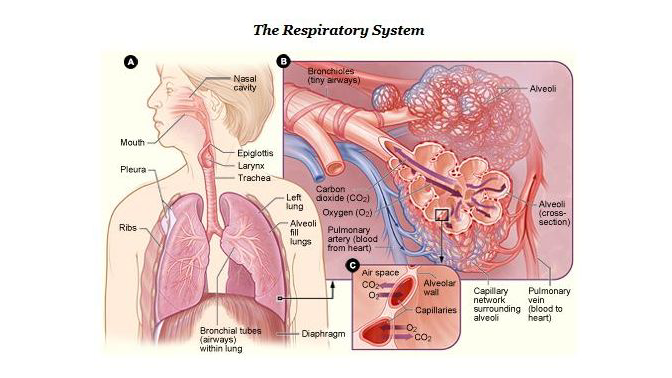

As discussed before, most metal 3D powder particles range in size from 10 to 70 microns. This is at the very edge of what is considered respirable and damaging to our lungs. While contact physically is to be avoided since it may initiate irritation and potential dermatitis, there is greater concern about the long-term inhalation exposure risks of these powders. Particles of the size range in this process can get deposited in the tracheo-bronchial region (see Figure 4), per work published by Jenson and Goldich. Ultimately, these particles are discharged from the body or swallowed, but effects of long term exposure for the wide range of metals and alloys is not fully studied, which is why suppliers insist on respirators (more on that in the next post). It is worth pointing out, though that it appears that while metal 3D printing powders are small enough to travel past the nasal cavity if inhaled, their sizes are large enough that respiratory damage in the lungs is highly unlikely. Only particles under two microns are at risk of making it all the way to the alveoli and causing lung disease.

3. Inert Gas Asphyxiation

Inert gases are used in laser metal 3D printers to reduce the reactivity of the metal for processing purposes. Most metal 3D printers either use nitrogen or argon. Inert gas asphyxiation is the main risk due to oxygen being displaced by either of these gases if they have leaked for any reason. Since neither gas is detectable by humans, victims do not realize that they are inhaling air depleted of oxygen and as a result this can have a serious impact. The human body is used to atmospheric percentages of oxygen (21 percent) and values below 19.5 percent can be harmful and are defined as oxygen-deficient per OSHA. Thus, any user of nitrogen or argon gas (and this applies to any process using inert gases), especially in small spaces such as a closed room, needs to be aware of this risk and protect against it.

4. Environmental Impact

A key challenge with powder-based processes lies in collecting the stray or “fugitive” powder from different locations, such as the tool, PPE, or containers and vacuum systems, and disposing them into temporary storage. During this period, the risks of fire/explosion and inhalation remain. Additionally, the storage typically results in loose powder and solid waste as well as water with powder particles, both of which need to be disposed into the outside world and could pose an environmental hazard. I will discuss this further in a future post, when I attempt to look at some of the environmental aspects around this technology.

Blog Post Disclaimers

This blog is intended to supplement the supplier training you must receive before using the equipment, and is not meant to replace it. In case of conflicting information, your supplier’s training and equipment requirements override any discussion here. PADT and Gardner Business Media assume no legal responsibilities for any decisions or actions taken by the readers of this document.

My personal experience derives specifically from the use of Laser-based metal 3D printing tools, specifically Concept Laser’s MLab Cusing R equipment. I expect a majority of this information to be of use to users of other laser-based powder-bed fusion metal systems and to a lesser extent to Electron Beam systems, but have no personal experience to vouch for this.

Local, state and federal regulations vary, and are important. Partner with your local fire marshal (or equivalent authority) as a starting point and take them along with you every step of the way. If in the U.S., familiarize yourself in particular with OSHA’s guidance on dust explosions and NFPA 484, the National Fire Protection Association’s standard for combustible metals.

About the Author

Dhruv Bhate

Dhruv Bhate is a senior technologist at Phoenix Analysis & Design Technologies (PADT) where he leads R&D efforts in additive manufacturing, with a focus on high performance polymers and metals. Prior to joining PADT, Dhruv spent seven years at Intel developing several laser-based manufacturing processes, taking them from early-stage research to high-volume manufacturing. He also spent a year in the automotive industry, working for India’s largest car manufacturer, Tata Motors.

Dhruv has a Ph.D. in mechanical engineering from Purdue University where he developed constitutive and failure models for the prediction of fatigue fracture in ductile metal alloys. Prior to this, he obtained his M.S. from the University of Colorado at Boulder where he studied the phenomenon of adhesion in Micro-Electro-Mechanical Systems (MEMS) structures.

Dhruv’s passion lies in combining theory, experimental methods and simulation to solve challenging problems in new and effective ways. He has two patents, 16 peer-reviewed publications and more than 30 conference presentations to his name.

Related Content

AddUp Receives ASTM Additive Manufacturing Safety Certification

AddUp Inc. announces that it has received the ASTM Additive Manufacturing Safety (AMS) Certification, becoming the first OEM in the AM industry to achieve this significant milestone.

Read MoreSLM Solutions, Assembrix Work to Ensure Secure Remote Printing

Following the integration of Assembrix VMS software into SLM Solutions’ machines, both companies are now working to ensure the enhanced safety and full protection of customers' intellectual property, which is made possible through the utilization of blockchain and encryption technologies.

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreDurable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read MoreRead Next

Installing a Metal 3D Printer, Part 2: Facilities

What facility adaptations are necessary when installing a metal 3D printer? PADT documents the steps it took to support a Concept Laser Mlab Cusing R in this second post in a five-part series.

Read MoreInstalling a Metal 3D Printer, Part 4: Prevention and Mitigation

PADT’s fourth blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks with a focus on prevention.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More