Tooling

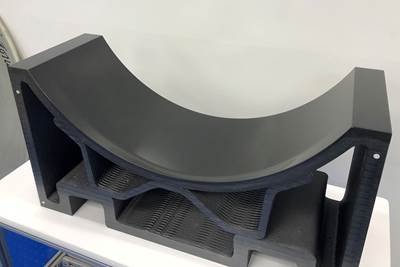

Airtech Validates High-Temperature Polymer for Large-Format Tooling, Moldmaking

According to the company, the polymer is well suited for high-temperature applications such as hot forming tools, autoclave molds, oven molds and self-heated molds.

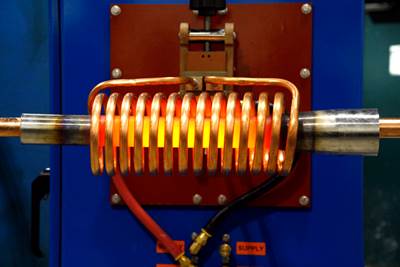

Read More3D Printing Supports Induction Coils — and Emergency Needs

As a participant in Michigan’s Project DIAMOnD initiative, Tucker Induction Systems received a 3D printer to use any way it saw fit, provided the capacity remains available in case of emergency. Use cases and lessons learned as part of this distributed manufacturing network.

Read MoreHow An Airline Addressed Supply Chain Issues with 3D Printing

COVID-19 not only grounded most of Scandinavian Airlines’ (SAS) fleet in 2020, but also limited its access to engine covers critical for safe storage. CNE Engineering used BigRep machines to 3D print molds to produce the covers.

Watch3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

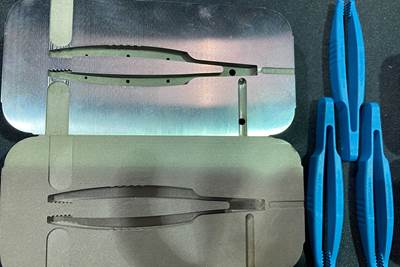

Read More3D Printing Enables Mold Shop to Rapidly Prototype Medical Parts (Video)

A case study involving Mantle’s 3D printing technology allowed moldmaker Westminster Tool to go from design to injection molded prototype medical parts in three weeks.

WatchHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreThermwood LSAM 510 Additive Printer Useful for Molding, Tooling

RAPID 2022: Thermwood’s LSAM 510 additive printer features a single fixed gantry and a 5 × 10 ft. moving table with a 4 ft. maximum print height and a maximum temperature of 450°C.

Read More3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

ListenHow to Improve Polymer AM Productivity 20X

A fast cycle time is critical to efficient production 3D printing, but it’s not the only thing. How you choose the right parts for AM, prepare jobs for production, and manage post processing will have just as big an impact on total 3D printing throughput. It all needs to work together to achieve maximum productivity.

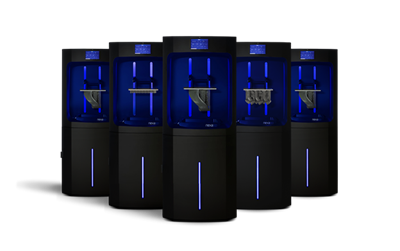

WatchMicro 3D Printer Complements Micro Moldmaking Capabilities

For micro mold provider Accumold, the Nano Dimension 3D printer provides a way to produce micro-scale prototypes and rapid tooling.

Read More