Tooling

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Watch8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

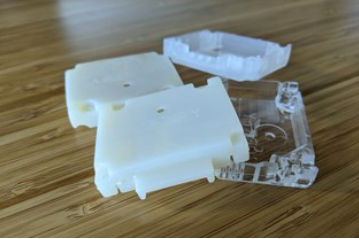

Listen3D Printed Mold Tooling Advances in Performance With Proprietary Resin

Material improvements offer turnkey production and cost trimming with 3D printed mold tooling. A new, proprietary resin addresses the current limitations associated with 3D printing in polymer.

Read MoreIce 3D Printing of Sacrificial Structures as Small as Blood Vessels

Using water for sacrificial tooling, Carnegie Mellon researchers have created a microscale method for 3D printing intricate structures small enough to create vasculature in artificial tissue. The biomedical research potentially has implications for other microscale and microfluidics applications.

WatchMarkforged Adds Simulation Feature to Additive Manufacturing Software

The software’s virtual testing can validate the strength of advanced composite parts and automatically optimize print parameters to lower cost and speed production.

Read MoreBigRep Additive Manufacturing Technology for Faster Iterations, Production

Formnext 2022: BigRep’s printers are open-material systems, offering users more flexibility with filament options.

Read MoreMassivit 3D Expands Systems, Materials Portfolio to Automate, Speed Up Composite Production

Formnext 2022: These additive manufacturing systems utilize the company’s Cast In Motion technology, which is said to enable direct printing of complex molds using high-performance casting materials.

Read MoreAdditive Brings Changes, Even if the Wrench Stays the Same

The argument that begins with what additive cannot do is probably right, and misses a great deal.

Read More5 Can't-Miss Conversations on Additive Manufacturing

The top 5 most-downloaded episodes of the AM Radio podcast reveal some of the most relevant conversations in AM today, including opportunities for bridge production, new possibilities in plastics, and when to embrace 3D printing for manufacturing at scale.

ListenSaint-Gobain 3D Prints Tooling for Elevated Efficiency

BCN3D is assisting Saint-Gobain production with its 3D printers manufacturing tooling in-house.

Read More