Tooling

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

In a recent case study, Alpine Advanced Materials partnered with Nexa3D to produce 3D printed tooling for injection molded composites. Utilizing Nexa3D’s XiP desktop 3D printer and its Freeform Injection Molding process, Alpine was able to reduce prototype tooling production time and cost alike for its customers.

Read More4 Weeks from Design to Molded Part for Medical with Metal 3D Printed Tooling

Mold builder Westminster Tool applied the Trueshape process from Mantle to produce tooling to take a medical device from prototype mold to full-scale production in a matter of weeks.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreHP, GKN Additive Partner to Qualify Diverse Range of Materials for Additive Manufacturing

The collaboration focus is to combine HP’s Metal Jet S100 technology with unique material offerings to take tooling to the next level while addressing unique customer challenges.

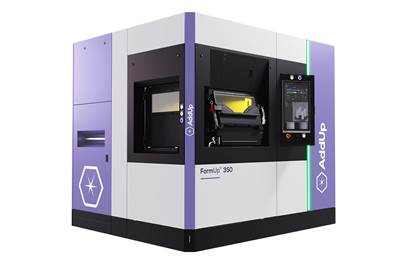

Read MoreAddUp, WBA Investigate Additive Manufacturing for Moldmaking Tooling Study

The additive manufacturing (AM) tooling study focused on six select companies, offering them the opportunity to test the introduction of AM and specifically implement the technical and economic advantages of AM technology for their injection molds.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

ListenDOE Awards Nearly $3 Million to Develop Additive Manufacturing of Modular Wind Blades

The industry partners received the award to develop automation in additive manufacturing of tooling for large-scale wind blades that can accommodate continuous changes in blade geometry and scale.

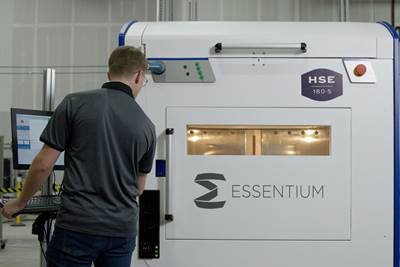

Read MoreGerman National Railway Certifies Essentium HSE Printing Platform, Materials

Essentium’s additive manufacturing solutions will enable Deutsche Bahn to increase its fleet availability through easy and fast replacement of parts and tools.

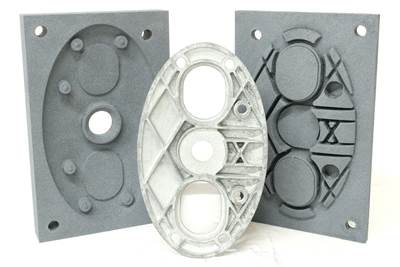

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

WatchWestec Plastics Partners With Mantle to Speed Tooling Production

Using Mantle's technology, Westec says it can complete up to 70% of the job and have its toolmakers handle the specialized steps only humans can do.

Read More