Tooling

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

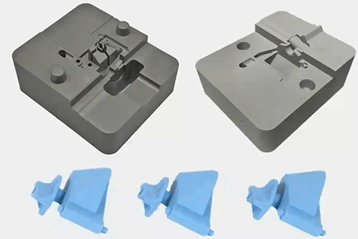

Read MoreMantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

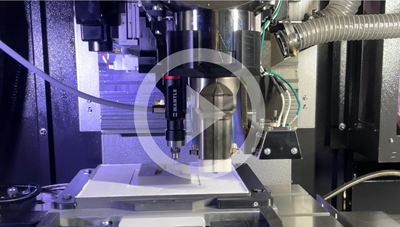

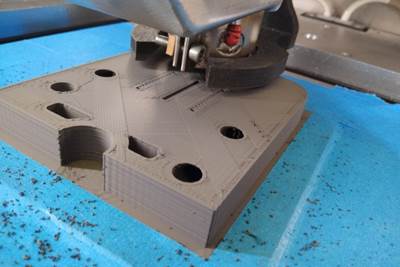

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

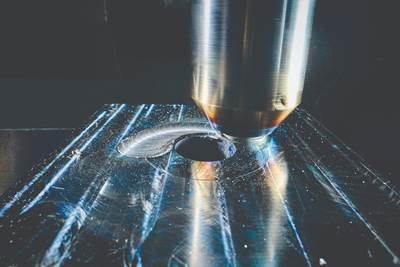

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

WatchResearch Partners 3D Print MIM Tool With Near-Contour Cooling

Compared to a conventional approach in machining, the use of an additive manufacturing process to produce a MIM tool reduces the total production time from around 8 weeks to approximately 5 days.

Read MoreMazak MegaStir Will Be Exclusive Tooling Supplier for Meld Solid Deposition Technology

Mazak MegaStir will provide its hard metal expertise along with tooling specifically developed for the Meld process that also incorporates the use of friction as part of its solid deposition process.

Read MoreAddUp AISI 420 Steel Enables More Complex, Efficient Injection Tooling Molds

This stainless steel is commonly used to manufacture molds for plastic injection molding, as it has both high mechanical strength and good corrosion resistance.

Read MoreMC Machinery’s Wire-Laser Metal 3D Printer for Efficient, Versatile Processing

The printer applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

Read MoreNexa3D Acquires Addifab

The maker of polymer 3D printers and the creator of technology for injection-molding-ready printed tooling are fully joined after announcing a collaboration last year.

Read MoreMantle’s High-Precision Shaping for Automating Precision Toolmaking

The High-Precision Shaping feature expands the capabilities of Mantle’s hybrid metal 3D printing technology, enabling finer feature creation and dramatically expanding the geometries compatible with its TrueShape process.

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read More