Tooling

Is AM in Competition With Conventional Manufacturing? Tooling Is on Conventional’s Side

Recent articles consider the other way additive manufacturing is advancing production: not by 3D printing parts, but in the ways 3D printed tooling makes casting, machining, molding and other processes better.

Read MoreThermwood, Boeing, Navy Collaborate on Large-Scale Composite Tooling Research

Thermwood’s large-scale additive manufacturing (LSAM) machine was selected as the large-format additive manufacturing (LFAM) machine to conduct the technology development.

Read MoreMore Examples of How 3D Printed Tooling Is Transforming Part Production

Illustrations of successes with tooling made through additive manufacturing in applications involving composite parts, robots, metal coating, die casting and construction.

Read MoreFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read MoreJob Shop’s AM Journey Takes It from Production to Tooling

Despite the fact that RPG was prepared to start with production metal additive manufacturing, the job shop couldn’t ignore the benefits of 3D-printed tooling.

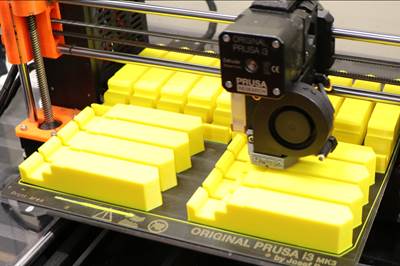

Read MoreMaterials are Key to 3D Printed Injection Mold Tooling

IC3D’s combination of experience with filament production, building 3D printers and service bureau work is helping it expand the possibilities of 3D printed injection mold tooling.

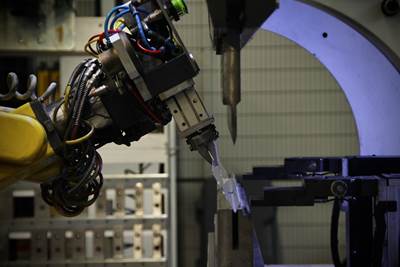

Read MoreTopology Optimization Software Enhances Gripper Reliability

Design software with built-in topology optimization and reconstruction features enabled Preziosa Francesco SRL to use Desktop Metal’s Studio System to improve the performance of a robotic gripper.

Read MoreA Resonant Harmony for Bell Casting and 3D Printing

When a 180-year-old bell foundry sought an alternate solution for expensive metal mold patterns, it turned to a 125-year-old company for a modern solution: large-format additive manufacturing.

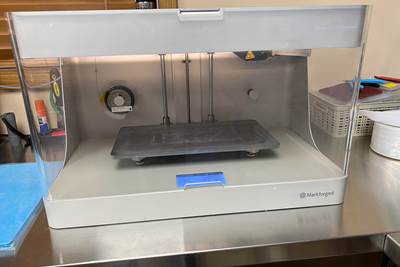

Read MoreSolving MRO Challenges with Bound Metal Deposition

Three case studies reveal how Desktop Metal’s second-generation Studio System bound metal deposition printer eliminates common safety hazards of metal AM, enhancing the technique’s value for maintenance, repair and operations (MRO) applications.

Read More3D Printed Tooling Supports Prototype Foam Seating

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

Read More