The goal for Tucker Induction Systems’ products is to deliver “a specific heat pattern to a specific part as quickly as possible,” says Josh Tucker, head of purchasing. The Shelby Township, Michigan, company has been producing induction coils and related accessories and systems for more than 40 years, and deeply understands the challenges associated with the targeted application of heat. The small business has just 16 employees, including the talent needed to produce the copper coils at the heart of each induction system through a combination of automated and manual processes. These coils and systems also need tooling, which is commonly machined from stock material; now, thanks to a grant-funded initiative, Tucker Induction is making strides in implementing a different, more flexible means of manufacturing some of these plastic components: desktop 3D printing.

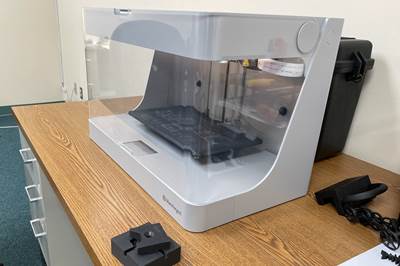

Tucker Induction Systems received a Markforged Mark Two 3D printer as part of its participation in Project DIAMOnD. The company is free to use to the machine for its own operations, on the condition that it remains available for emergency applications.

Tucker Induction is one of 300+ participants in Project DIAMOnD, an initiative led by Automation Alley that placed MarkForged 3D printers at small and medium manufacturing businesses in Michigan’s Macomb and Oakland counties. Project DIAMOnD stands for Distributed, Independent And Agile Manufacturing On Demand; funded by the Coronavirus Aid Relief And Economic Security (CARES) Act, the initiative was formed in response to equipment shortages during the covid-19 pandemic.

Participants in the program received a 3D printer for free that is networked to all the others, on the condition that they will undergo training, keep material on hand, and maintain the printer so that it is ready to respond to any new crisis. When the Project DIAMOnD network is not being used for emergency response, however, manufacturers are free to use the machines for anything they’d like. For Tucker Induction Systems and many other participants, this has been a low-risk way to get started with 3D printing, and perhaps prepare for a more additive future.

Manufacturing for Induction

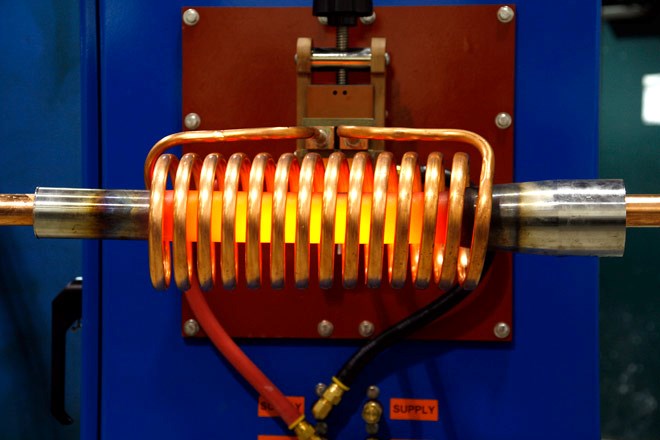

Induction heating is used in a range of applications from forging to selective heat treating of metals. For the latter, induction is typically faster and more cost-effective than heat treating an entire component; each coil is customized to the shape of the part and the area to be treated, and the process can be adjusted in terms of the time, power and frequency to achieve the desired result.

Induction coils precisely deliver heat to a workpiece. (See the process in action.) While Tucker Induction Systems is actively seeking a solution for 3D printing the coils themselves, prototypes and other parts of these systems can be produced with its FFF machine. Photo Credit: Tucker Induction Systems

As an equipment provider for this process, Tucker Induction Systems is a high-mix, low-volume manufacturer. The company sells only a few automated systems per year; the main part of its business is manufacturing induction coils and any necessary custom tooling, plus fine-tuning the induction “recipe” to help the customer. The coils themselves, usually made from copper through machining, bending and/or brazing, tend to be long-lasting. Depending on the application, some induction coils last hundreds of thousands of cycles before requiring repair — so the company is most commonly producing these parts in quantities of just one or two at a time.

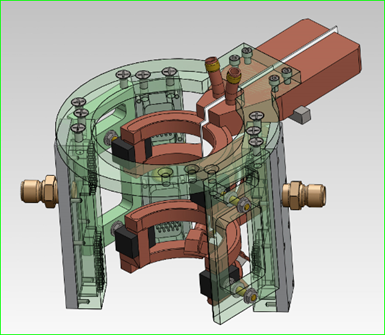

An induction coil system can be quite complex. Although almost all rely on copper coils to produce heat, those coils also need supports, quenching and other components to make the process work. Photo Credit: Tucker Induction Systems

“If someone orders more than five of something for a single machine, we start to wonder why they need so many,” Tucker jokes.

The Markforged Mark Two that Tucker Induction Systems received upon joining Project DIAMOnD was the company’s very first 3D printer — though not, perhaps, for lack of trying. Josh Tucker has been following additive manufacturing (AM) technologies for years now, hoping and then searching for a suitable means of 3D printing copper. The complexities of the coils, workforce strains, and lengthening lead times make 3D printing an attractive option for producing the copper components, but so far the company is still looking for the right fit in terms of both capacity and capabilities for producing these components.

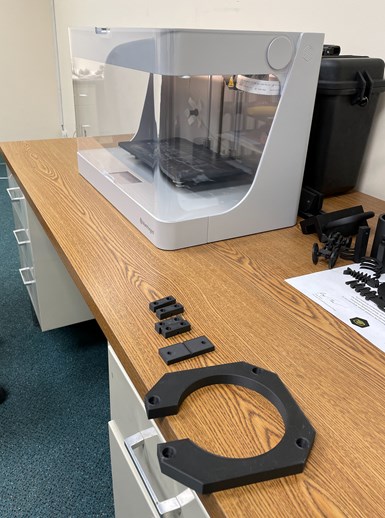

Fixtures for machining, inspection and more were among Tucker Induction Systems’ first uses for the 3D printer.

The desktop fused filament fabrication (FFF) 3D printer can’t make coils, but Tucker quickly discovered many other uses for the machine — producing fixtures for machining, prototypes of particularly challenging coils and more. Eventually, he also realized that the Onyx material used on the Markforged printer had properties suitable for the custom supports most coils require. Because the induction process produces a magnetic field to heat the part, the coil’s supports must be nonmagnetic. They must also offer some heat resistance and be able to hold up to repeated liquid exposure during the quenching step in each induction cycle.

Typically, Tucker Induction Systems machines these supports from a material such as G10 laminate or Delrin polymer, but is now producing many of these components through 3D printing. The carbon fiber-reinforced Onyx polymer offers similar properties to these materials in terms of heat resistance, and is also nonmagnetic and nonconductive. Additionally, supports can be 3D printed with relative ease; a part printed with Onyx does not require machine setup time or tooling for workholding, and its design is not limited by cutting tool access. The company has benefited from the speed of iterating these supports, as well as greater geometric freedom that 3D printing provides.

The carbon fiber-reinforced Onyx material offers similar properties to the G10 and Delrin materials Tucker Induction Systems has historically used for coil supports, with the added benefits of rapid iteration and new design opportunities.

“We are the limits on these machines,” Tucker says, citing the creativity that a 3D printer makes possible. In just a short time, this desktop machine has become an important part of the company’s operation.

Not an Island

The lessons that Tucker Induction Systems is learning with this single printer are not isolated, however. As part of the Project DIAMOnD network, the company has access to resources and community among all the other participants. Automation Alley hosts ongoing training and competitions for the various nodes on the network, and these 300 manufacturers have come to know one another and to work together.

Josh Tucker describes how, during the Command Center activation for Ukraine, the Mark Two changed between two different part designs automatically. In the foreground, a test print that was completed as part of the initial 3D printing training (it reads: “Automation Alley Certified Essential,” speaking to the emergency roots of the Project DIAMOnD initiative).

The most visible example of this collaboration thus far came as a result of the ongoing conflict in Ukraine. In April of 2022 Automation Alley identified a need for tourniquet components and chose to activate the Project DIAMOnD “Command Center” to produce these parts.

When activation happens, each connected 3D printer receives instructions in the form of a protected print file (so that it can’t be changed or tampered with), predetermined printer settings, and a requested quantity. Any 3D printer already making parts will complete current jobs in its queue before switching over to the requested parts; the same lack of tooling that makes 3D printing attractive for producing custom coil supports also enables manufacturing to change from one part number to the next with ease in an emergency.

Josh Tucker witnessed the activation firsthand, and watched as his Markforged printer first produced tourniquet clips and then automatically switched over to printing tourniquet handles. “I only realized it because the toolpaths and the sound of the printer changed,” he says. All told, the Tucker Induction Systems printer made 44 clips and 10 handles in just a few days that were contributed toward Project DIAMOnD’s goal to deliver components for thousands of tourniquets.

Realities of Distributed Manufacturing

The hands-off experience of watching one’s 3D printer change from part to part speaks to the promise of distributed manufacturing through this technology: A digital process that is not reliant on tooling needs only instructions and material to change what it is making, so that production can happen anywhere the equipment exists.

In practice, though, there are many more reasons that Project DIAMOnD works as well as it does. The network is not made up of unattended 3D printers placed in remote locations, but reliable machines located in qualified manufacturing facilities that have been contracted to tend them for this purpose, with trained personnel. The printers in the network are almost all identical (like Tucker Induction Systems, most nodes have a Mark Two — though a few are equipped with an X7 polymer or Metal X system), which makes it possible to distribute reliable printer settings along with the design file. Collectively, these machines are tasked with making relatively simple parts well within their capabilities. This network is under the oversight of a governing body, Automation Alley, that identifies appropriate needs, handles logistics and distributes production. In the case of the Ukraine project, the organization’s oversight extended all the way to collecting and inspecting the parts, plus performing any needed cleaning, deburring or support removal.

Distributed manufacturing is not yet simple or easy, but the Project DIAMOnD network offers an illustration of the foundation such a model for production needs, and a real look at its promise. When all the right pieces come together, 3D printing can and has made distributed manufacturing possible — enabling faster lead times, machine redundancy, knowledge sharing and more. While activation for this network has so far has been limited to emergency circumstances, it could also be used to help individual manufacturers borrow printer capacity to divide and conquer specific jobs; Automation Alley is actually working on functionality that would allow network participants to distribute work in this way.

“If I got an order for thousands of printed parts, that job would be too big for just this printer. I wouldn’t even be able to quote it,” Tucker says. “But if I can distribute it across the network, a job like that becomes possible. We are all individual businesses, but we are one with the printers.”

An Additive Future

After the Ukraine initiative, Project DIAMOnD printers went back to making parts designed by their individual facilities. As other machines returned to printing check gages, prototypes, hand tools and more, Tucker Induction Systems’ Markforged switched back to making induction coil supports.

Although these machines are part of an experimental network, the experiment seems to be proving its dual hypotheses that distributed manufacturing is doable, and that manufacturers presented with 3D printing technology will find the opportunities for it. That’s certainly true for Tucker Induction Systems, and Josh Tucker hopes this initial adoption will carry the company even farther, toward the dream of 3D printing coils in copper one day.

“We’ve learned so much just from that little machine,” Tucker says. “But for copper we are still on the outside looking in, watching closely so that when the time comes, we’re ready to hit the ground running.”

Related Content

Better, More Compact Radio Frequency Devices Through 3D Printing

3D printing technology company Fortify is applying its photopolymer process and material developed with Rogers Corporation to serve the expanding RF market.

Read MoreEaton Developing Carbon-Reinforced PEKK to Replace Aluminum in Aircraft Air Ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreAdvancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreRead Next

3D Printing Increases Efficiency Of Wind Turbine Blade Alignment

A Markforged digital repository and 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

Read MoreAdditive Manufacturing and the War in Ukraine: AM Radio #19

In this latest episode of the AM Radio podcast, we dive into the ways that AM is providing aid and also being affected by the conflict in Ukraine.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More

.jpg;width=70;height=70;mode=crop)