More Examples of How 3D Printed Tooling Is Transforming Part Production

Illustrations of successes with tooling made through additive manufacturing in applications involving composite parts, robots, metal coating, die casting and construction.

Is there a manufacturing process or sector dependent on tooling that has not turned to additive manufacturing as a means of making that tooling more quickly or effectively? The latest issue of Additive Manufacturing magazine focuses on tooling; it includes articles describing 3D printing making tooling for assembly, foam molding, injection molding, sand casting and workholding for machining. But the tooling applications don’t end there. Here are photos of a few others:

(1) Lincoln Electric Additive Solutions uses large-scale wire-arc AM performed by robots to 3D print metal tooling for making polymer composite parts.

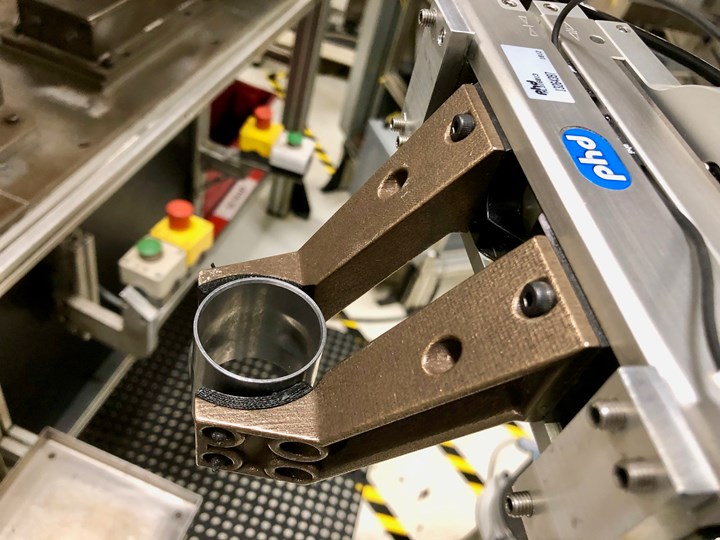

(2) Thyssenkrupp Bilstein’s Ohio suspension plant uses Raise3D printers as a fast and economical way to obtain custom end effectors for robots.

(3) PMT Shielding Solutions controls metal coating processes for electronics components by using Plural Additive Manufacturing machines to 3D print masking tooling.

(4) Exco Engineering, leading manufacturer of die cast tooling, has turned to AM to streamline production, as in the case of these water jackets sections for making engine blocks, tool components made via laser power bed fusion on a machine from EOS.

(5) Gate Precast uses 3D printing to make tooling for concrete forms used in construction, tooling traditionally made from wood and made by hand that is in this case obtained from suppliers using large-format polymer AM machines from Cincinnati Incorporated and Thermwood.

Related Content

-

When Advocacy Leads to Adoption: How Pella Applies (and Manages) AM Capacity

The window and door maker offers a picture of successful, widespread 3D printing adoption across the different needs of a manufacturing organization. The outreach and education effort worked. Now, here is the next phase.

-

Complete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

-

Video: 3D Printed Hand Tools in Action on Pella Corporation Factory Tour

Examples include an invention for quickly installing window and door weather stripping, a fitting for giving the proper angle to a nail gun, and a clip for which the color is an important feature.