Tier 1 automotive supplier Mahle GmbH (Stuttgart, Germany) uses metal AM technology to produce end-of-arm tooling (EOAT), fixtures and toolholders for its manufacturing operations around the world. Previously, the company had designed manufacturing aids for its own operations and either interrupted its own machine shops to have them produced or turned to service bureaus to have them 3D printed.

Not long after joining the company in 2012, Mark Brooks, design technician, Mahle Engine Components USA Inc. (Morristown, Tennesee) — a CAD designer by background — stepped in to run the facility’s polymer additive printer. In 2016, he was asked by his boss to research and purchase a metal AM printer to produce components for a new production line being installed at the facility.

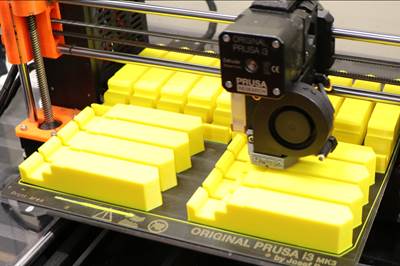

Xact Metal’s XM200C 3D printer offers a build volume measuring 5" × 5" × 5" and is compatible with a range of materials including stainless steel, super alloys and tool steels. Source: Xact Metal

Over the next few years, Brooks looked at printers from five different companies. He also identified a single part that was necessary for use on the new production line and that was considered unmanufacturable (or, at least affordably unmanufacturable) with conventional metalworking processes. As a test to better assess the capabilities of each of the printers under evaluation, Brooks had each printer OEM produce a few of these parts on their machines using his design and send them back to him. Different companies sent printed parts back in different materials.

“Some of the suppliers printed the benchmark part in aluminum, some in M300 [a maraging steel alloy], some in tool steels and one even produced them in titanium — basically, they sent us whatever they had on hand and happened to feel like printing,” Brooks recalls. To see how durable the parts were, they were installed in 12 locations on six production lines already operating at the Mahle facility and most of those parts are still in place and, he says, are holding up well.

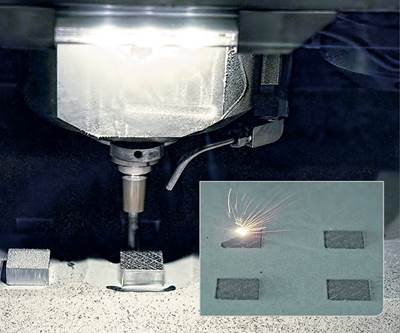

Automotive Tier 1 Mahle uses a direct metal laser sintering/solidification (DMLS) printer to produce a variety of maraging steel manufacturing aids for its facilities around the world. Not only does printing the aids free up time in the tool shop, but metal additive printing can turn parts around much faster and at lower cost than conventional manufacturing. Source: Xact Metal

Eventually, after more visits and more evaluations, Brooks’ facility purchased an XM200C laser powder bed fusion printer from Xact Metal Inc. which was installed at the end of 2018. Since then, Brooks has used the printer to produce tooling for robots, coating operations, fixturing, sensor brackets and toolholders not only for his own facility but for other facilities around the world. The printer is used exclusively to produce parts in M300, which saves the time and cost of switching between metal powders. Brooks says that he conducted a cost analysis and found that the company had achieved ROI within the first 6 months of owning the machine.

“This was our first foray into metal additive and we found it took stress off our machine shop, since we no longer have to interrupt other work to have manufacturing aids machined for us,” Brooks explains. “From completed design to finished part in hand, we average a day and a half, which makes it much faster and less costly to produce. Also, since you can iterate so fast, if something isn’t quite right the first time, you can easily modify it and print another one very quickly.”

More From This Author

Peggy Malnati is a Detroit-based contributing writer for CompositesWorld magazine, for which she primarily reports on automotive and ground transportation. SUBSCRIBE HERE

Related Content

7 Lessons From General Atomics on AM for Aircraft Part Production

A manufacturing leader overseeing the way additive manufacturing is transforming unmanned aerial systems (UASs) offers observations about succeeding with 3D printing as an aircraft production process.

Read More3D Printed Calibration Fixtures for Ultrasonic Flowmeters

Calibrating industrial flowmeters requires temporarily attaching equipment to pipes to check the flow and make adjustments. Emerson shares how 3D printed fixtures can simplify the connection and make calibration faster, easier and more accurate.

Read MoreWhen Advocacy Leads to Adoption: How Pella Applies (and Manages) AM Capacity

The window and door maker offers a picture of successful, widespread 3D printing adoption across the different needs of a manufacturing organization. The outreach and education effort worked. Now, here is the next phase.

Read MoreCombining Metal and Polymer for Better 3D Printed Tools

Applications prone to wear call for more durable tooling than 3D printed polymer alone, but full metal is not always necessary.

Read MoreRead Next

GW Plastics Bets on Metal 3D Printing for Conformal Cooling

An investment in a hybrid metal 3D printer is enabling moldmaker GW Plastics to produce better-performing molds with conformal cooling.

Read MoreWhy Today’s ROI Is the Wrong Measure: Seeing Additive Manufacturing for the Transformation It Brings

Today’s ROI is based on assumptions and limitations that will change. Here are examples of companies getting ready for tomorrow.

Read MoreFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read More

.jpg;width=70;height=70;mode=crop)