Much of the advice for CNC machine shops or other established manufacturers looking to implement 3D printing recommends the same basic progression: Start with a polymer or composite printer and put it to use for tooling applications around the shop to learn about the technology and explore its possibilities, then move on to production additive manufacturing if and when it makes sense. But RPG Industries Inc., a machining job shop in Tipp City, Ohio, didn’t need to be convinced of the potential of additive manufacturing (AM) for production. “3D printing really intrigued me,” says the company’s president, Robert Ginsburg. “To me that was just one of the neatest things. You can design something on a computer, hit a button and the next day you had a functional part.” So when RPG had the chance to add production metal AM capabilities in the form of a Metal X system from Markforged, Ginsburg grabbed the opportunity. But although the shop was ready to start its additive manufacturing journey with production, it didn’t skip the tooling step entirely.

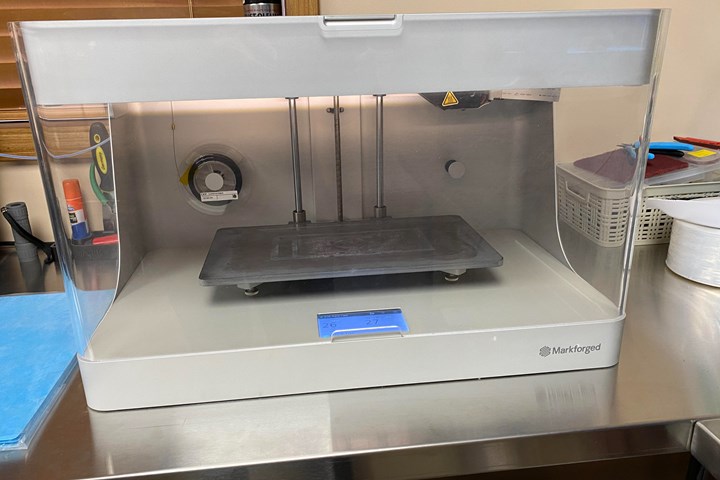

When RPG purchased its Metal X metal 3D printer from Markforged, it came in a package deal with a Mark Two composite printer. While the shop has used it for end-use parts and prototypes, its main use is to produce tooling for internal use.

When RPG purchased its Metal X, it was part of a package deal from Markforged that included a Mark Two composite printer. This machine prints parts in Onyx, which is Markforged’s composite base material consisting of nylon filled with micro carbon fiber. The Mark Two can also add layers of continuous carbon fiber for added strength. “With that continuous reinforcement, you can make some extremely strong parts,” Ginsburg says, including “parts that rival aluminum with less weight.”

While RPG has used the Mark Two to produce end-use parts (such as face shields during the beginning of the COVID-19 pandemic and brackets with carbon fiber reinforcement) and prototypes (including an initial version of a carburetor cap for a 1930s classic car that was used to test the fit before printing the final version of this replacement part on the Metal X), Ginsburg says its main use has been printing tooling for internal use. RPG thus reverses the job shop’s typical AM progression, starting with production but finding its way into tooling. Some of these tooling applications include:

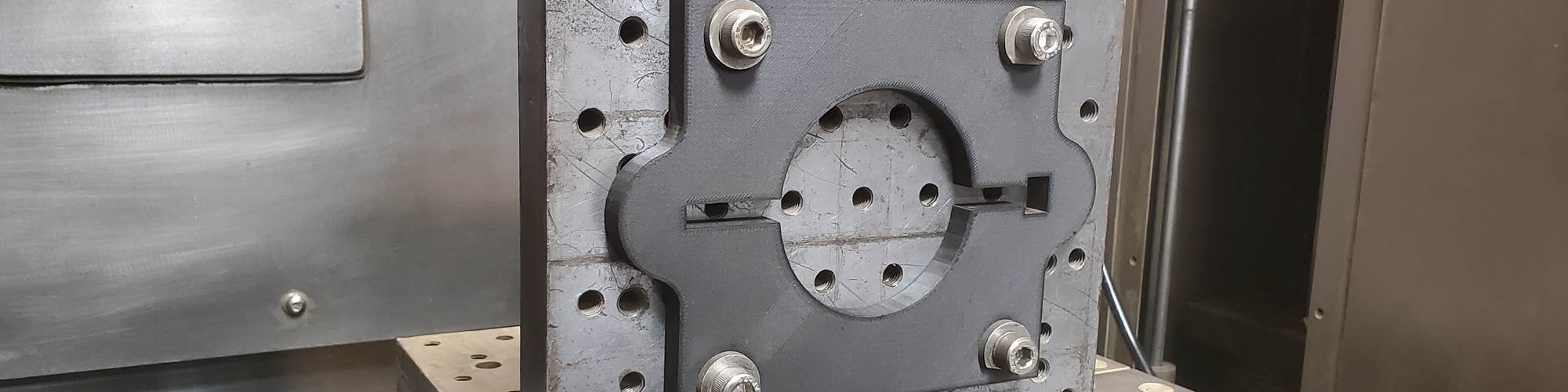

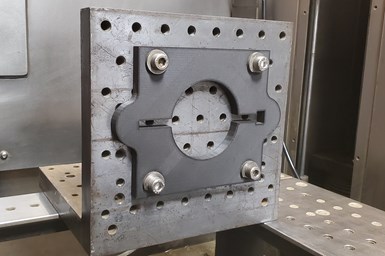

- EDM Guides. Ginsburg says that in some wire EDM and EDM drilling applications

, it’s helpful to use a guide. In these situations, he will design and print a composite guide on the Mark Two to ensure precise, accurate machining.

For some applications on its wire and EDM drilling machines, RPG will use the Mark Two to print a composite guide to help ensure precise, accurate machining.

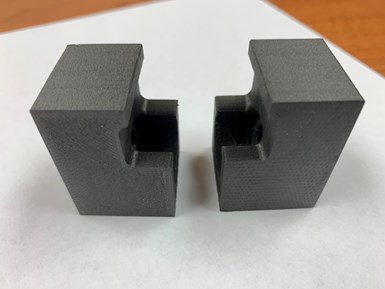

- Jaws for Difficult-to-Hold Parts. RPG has also used the Mark Two to

print custom workholding for parts that may be difficult to hold in traditional jaws. One recent example involved long extruded parts of various sizes, into which the shop was milling holes. When RPG first started the job, it printed composite jaws to hold the parts, but as the volumes have increased, the shop has transitioned to traditional machined jaws. Ginsburg also adds that, while the shop has not yet printed custom workholding for its lathes, that is a potential application as well.

RPG used these composite 3D printed jaws to hold long, extruded parts while holes were drilled into them.

- Organization Around the Shop. RPG has found many applications for

the Mark Two around the shop. For example, when installing the wash station and sintering oven for the Metal X, the shop 3D printed a number of brackets to mount the cables and keep them neatly arranged. Ginsburg has also found it useful to print other parts to help keep the shop organized, including a stand mounted to the same table as the sintering oven to hold some of this oven’s tools.

RPG designed and printed this stand that is mounted to a table near the sintering oven and holds a number of tools for it.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read MoreRead Next

FFF 3D Printing for Metal: Sintering Can Wait

Separating 3D printing from high-temperature processing is part of how the Markforged Metal X realizes a price less than established metal AM equipment.

Read MorePVD Coatings Solve Common 3D-Printed Mold and Part Problems

The right surface modification solution can alleviate a few common additive manufacturing pain points that typically require creating new molds or parts.

Read More10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

Read More