Topology Optimization Software Enhances Gripper Reliability

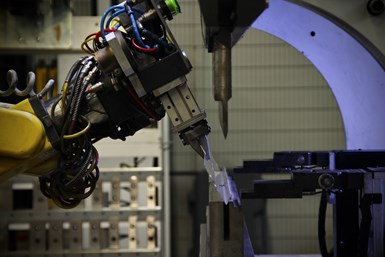

Design software with built-in topology optimization and reconstruction features enabled Preziosa Francesco SRL to use Desktop Metal’s Studio System to improve the performance of a robotic gripper.

The CNC-manufactured grippers Preziosa Francesco SRL used to hold parts in place during the operations of its automatic press brake bending system suffered from low traction and agility, threatening to compromise the shop’s operations. The new parts created in-house through AM improve upon these issues while decreasing lead times and simplifying the supply chain.

Photo Credit: nTopology

Preziosa Francesco SRL is a manufacturer of sheet metal cabinets, one which prides itself on the customizability of its standard line. To improve its workflow and stay competitive, the company invested in a robotic cell and an automated press brake bending machine.

This investment, worth hundreds of thousand euros, swiftly began running into problems because of a relatively cheap part: the robotic end effector’s gripper. The long lead times for CNC machining new, custom robot gripper sets for specific jobs created a bottleneck in Preziosa Francesco SRL’s process.

To solve this problem, the manufacturer partnered with design consultancy firm Additive Italia (also known as Add-It) to create a customizable part Preziosa Francesco could then manufacture in-house. Add-It was able to meet the customizability requirement — as well as improve upon other characteristics of the part — through creating reusable design workflows in nTopology.

Built-In Problems

Preziosa Francesco uses a FANUC M710-iC robotic arm to load metal sheets into its automatic press brake bending machine, orient and secure the sheets’ position during bending operations and remove the parts to the appropriate storage area. The two CNC-machined grippers traditionally attached to the arm created three technical challenges Preziosa Francesco and Add-It wished to overcome.

The original parts did not impose enough friction to ensure a good grip, especially when applications required precise positioning under high-load conditions. The parts were also too large for perfect agility, risking collisions with the machine at certain bending angles. Lastly, outsourcing to a CNC machining company meant slow, two-week lead times for manufacturing custom grippers — unacceptable, when Preziosa Francesco requires different grippers for different sheet thicknesses and blank sizes.

With nTopology’s topology optimization features and automatic reconstruction and smoothening, Add-It was able to create customized versions of its designs in only a few clicks.

Photo Credit: nTopology

Designing Solutions Through nTopology

“We immediately decided to start this project with nTopology due to the variety of grips that we could make,” says Gianluigi Rossi, design engineer at Add-It and lead designer engineer of this project.

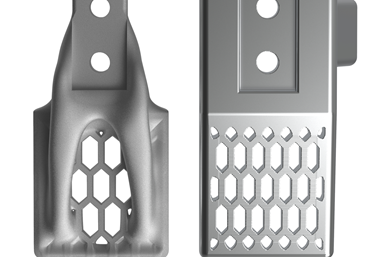

To enhance friction, Add-It designed a surface lattice and honeycomb-like perforation pattern on the gripper. The grooves of this traction pattern deform the softer aluminum sheets Preziosa Francesco uses, mechanically interlocking the parts.

Add-It also used nTopology’s topology optimization capabilities to reduce the gripper’s footprint without impacting performance. “We estimated the space that we needed to save in the volume of the clamps,” Rossi explains. “It was a matter of a few millimeters. Still, it was a few millimeters that counted in this application.” This small reduction in size enables the system to remain close to the press brake bending machine to perform more delicate robotic operations and handle smaller metal sheets without collisions or stoppages.

The design process proved swift, moving from concept to application within four days, rather than the two weeks previously required for production of a single gripper variant. With nTopology, the team automatically reconstructed and smoothened the topology optimization results. This eliminates a time-consuming manual step, and enables the generation of variations within a few clicks. “In one afternoon, we managed to make the component we needed,” Rossi says. “In a few minutes, we could change the type of grip and produce a part that was ready to manufacture.”

Ensuring Process Reliability with Reusable Design Processes

For Preziosa Francesco SRL, the redesigned gripper greatly improves process reliability, unlocking lights-out manufacturing and the full utilization of its robotic manufacturing system. The manufacturer also no longer needs to worry about supply chain issues from outsourcing, with its Desktop Metal Studio System able to produce parts on-demand. In-house AM production has also resulted in a 35% cost reduction for the part.

Preziosa Francesco and Add-It are looking into expanding their partnership to new parts, and continue to optimize the grippers. They are designing clamp replacements and spare parts for the company’s punching machine, while also attempting to design a version of the gripper that is twice as long to increase maneuverability and flexibility.

Related Content

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

Read MoreHybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

Read MoreRead Next

Video: Topology Optimization versus Generative Design

Why do these strategies matter in design for additive manufacturing (DFAM), and what’s the difference? A conversation with PADT’s Eric Miller explores AM and design, including its human element.

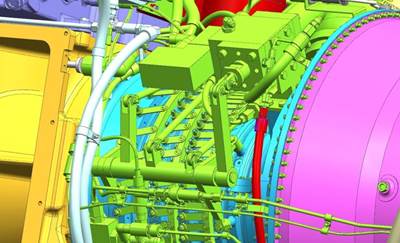

Read MoreTopology Optimization Delivers Nonintuitive Design Features for Legacy Part (Includes Video)

Refurbishing a legacy turbine engine for energy efficiency provided the opportunity to demonstrate topology optimization in concert with metal 3D printing. The design for this torque arm comes from computer simulation insight refined with a human touch.

Read MoreSolving MRO Challenges with Bound Metal Deposition

Three case studies reveal how Desktop Metal’s second-generation Studio System bound metal deposition printer eliminates common safety hazards of metal AM, enhancing the technique’s value for maintenance, repair and operations (MRO) applications.

Read More