Additive Manufacturing of Brackets Saves 1 Kilogram per Satellite

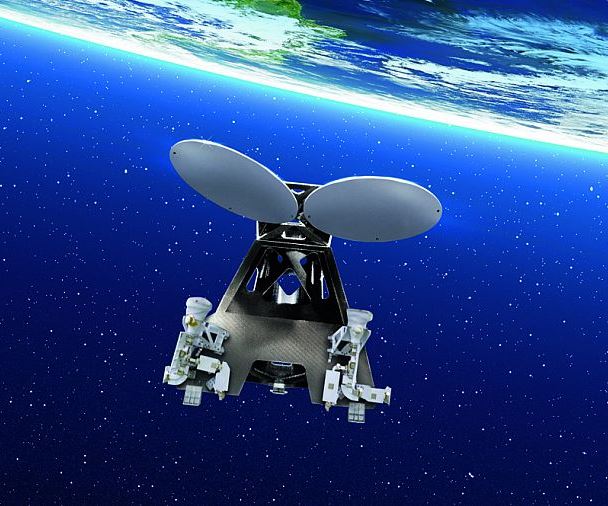

Because of complexity, material and quantity, spacecraft and satellite components are good candidates for additive production.

Satellites and spacecraft components are excellent candidates for additive manufacturing. One reason is that weight is critical—every ounce saved is an ounce that does not have to be launched into space. Another reason is that these parts are typically made of materials that are hard to machine. Still another reason is that the parts are made in low quantities. Additive manufacturing is unfazed by any of these challenges—part complexity, the machinability of the metal and the smallness of the batch size all do not affect its cost or difficulty.

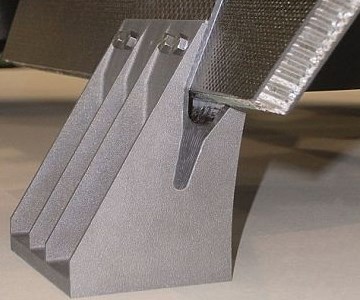

We recently wrote about how additive manufactured components are on their way to Jupiter in the Juno spacecraft. Another spacefaring success now comes from Airbus, which recently shifted the brackets that hold reflectors and other hardware on satellites to additive manufacturing. Redesigning the brackets for this additive production allowed Airbus to use less material, ultimately cutting nearly 1 kilogram per satellite.

Learn more about the application in this report from EOS.

(Brackets, by the way, are an underappreciated opportunity, says this additive manufacturing authority.)

Related Content

-

Supernova Creates Defense and Space Business Unit to Develop 3D Printing of Military-Grade Energetic Materials

Target applications for the new business unit include solid rocket motors which are critical components for the next-generation hypersonic platforms.

-

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

-

Reusable LOX/Kerosene Engine Completes First Successful Full-System Test Flight

Galactic Energy Space Technology announced the first successful full-system test flight of its Welkin 50-ton reusable LOX/kerosene engine. To date, this is the highest thrust LOX/kerosene engine in the Chinese commercial aerospace playing field which has officially entered the engineering and manufacturing phase.