Articles

AM 101: Hybrid Manufacturing

Additive manufacturing offers powerful capabilities alone, but even more opportunities are opened when AM is combined with subtractive processes.

WatchVideo: Topology Optimization versus Generative Design

Why do these strategies matter in design for additive manufacturing (DFAM), and what’s the difference? A conversation with PADT’s Eric Miller explores AM and design, including its human element.

WatchJabil Prepares for Production AM: It’s Down to the Basics Now

Jabil is getting ready for additive manufacturing to take its place as a production option in addition to conventional processes such as molding and machining. AM can and will fill this role, the company says — the focus now is on controlling cost and assuring quality and reliability.

Read MoreVideo: Controlled Porosity Can Be Functional Advantage Realized via 3D Printing

A wall of metal that looks solid is actually 90% dense, allowing gas to pass through. Mold venting is one application.

WatchA Total Plastic 3D Printing Process Designed for Production

Fast, predictable and precise, HP’s Multi Jet Fusion additive manufacturing process is ideal for production applications. Now there’s a new addition to the family of printers designed for even higher volume environments, taking HP’s portfolio of digital manufacturing solutions to a new level.

Read MoreMaterial Extrusion: Now with Metal

Challenging our thinking about materials in metal additive manufacturing and the possibilities with material extrusion technology.

Read MoreVideo: The STL File Can Produce Surface Defects in 3D-Printed Parts

Timothy Simpson of Penn State University discusses the influence of model definition in additive manufacturing and what to do about its effects.

WatchVideo: Support Structures Are Misnamed! How to Understand Anchors in Additive Manufacturing

Supports or anchors can account for a significant share of both the engineering investment and material use in metal additive manufacturing. Michael Hansen of SLM Solutions discusses the role and importance of support structures.

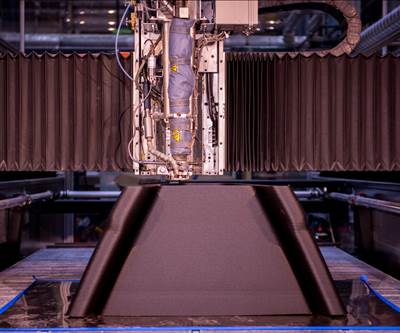

WatchThe Results Are In: Autoclave Tooling and Large Format Additive Manufacturing

SABIC and the University of Dayton Research Institute studied large-format additive manufacturing (LFAM) for metal autoclave tooling. The results are promising.

Read MoreVideo: Metal AM Affects Plastics Production via Conformal Cooling

Additive manufacturing allows cooling channels within mold tooling inserts to follow the form of the tool rather than being straight drilled holes. Here’s why this matters.

WatchVideo: The Impact of Part Orientation on Cost and Build Time in AM

A different build orientation might mean fewer layers and less support structure, though the part might need to be redesigned to take advantage of this different orientation.

WatchVideo: How Simulation Assists Directed Energy Deposition

Scrapping an AM part is potentially as costly as scrapping a machined part. Directed energy deposition is an additive process that can benefit from a resource that safeguards machining: simulation software.

Watch