Video: Controlled Porosity Can Be Functional Advantage Realized via 3D Printing

A wall of metal that looks solid is actually 90% dense, allowing gas to pass through. Mold venting is one application.

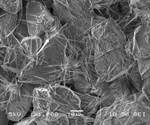

Between the bowl and the channel is a region that is 90% dense by design.

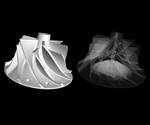

Additive manufacturing (AM) makes it possible to realize geometric features no other process can produce. The video below shows an example: A wall of metal that looks solid from a distance, but is actually just 90% dense, allowing gas to pass through it. Mold venting is one application.

Transcript

In this mold component, this drilled hole doesn’t go all the way through, but the air escapes anyway. It escapes because this was made additively. It was made on this machine from Matsuura, a powder-bed additive machine – metal additive specifically for injection mold tooling. And by controlling the parameters of the build only in this spot, the metal was made to be 90% dense. That means it’s a little porous, just porous enough so that the air can escape. The result is a solution enabled by additive for mold venting.

Related Content

-

Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

-

Complete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.