The Results Are In: Autoclave Tooling and Large Format Additive Manufacturing

SABIC and the University of Dayton Research Institute studied large-format additive manufacturing (LFAM) for metal autoclave tooling. The results are promising.

Share

Read Next

The metal tooling used for autoclaves during aerospace composite part manufacturing is burdened by the same obstacles of metal tooling at large: Material and CNC machining related costs, costs related to design changes, long lead times and long-term storage concerns.

Enter large-format additive manufacturing (LFAM) and a project partnership between SABIC and the University of Dayton Research Institute to find a solution.

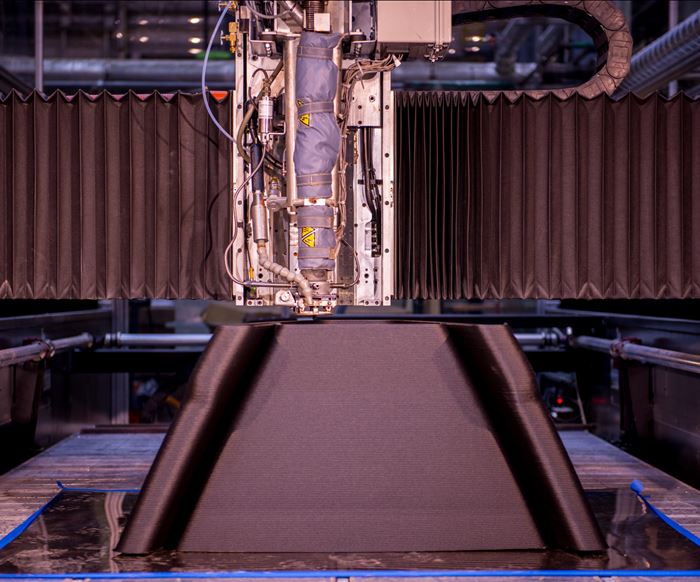

The team sought to create tooling able to withstand more than 10 autoclave cycles at 350°F while under 85 – 90 psi pressure, all while maintaining vacuum integrity and tolerances of ±0.005 inches before, during and after autoclaving. Using LNP Thermocomp AM EZ006EXAR1 compound (a combination of Ultem resin, well known for withstanding high temperatures, plus a filler package) as the material, SABIC printed the tool with Cincinnati Incorporated’s Big Area Additive Manufacturing (BAAM) machine. The final part —printed in just 2.5 hours — consisted of 140 layers and a double outer wall with a staggered line infill pattern.

After being machined to its final dimensions, SABIC sent the part to Tru-Design in Knoxville, Tennessee for a proprietary coating application that can bond to high temperature LFAM feedstocks, maintain structural integrity during autoclave cycling and provide a vacuum-tight tool surface. With the coating applied, the tool began multiple rounds of rigorous testing at both the University of Dayton and SABIC’s Polymer Processing Development Center in Pittsfield, Massachusetts. Scanning and vacuum testing confirmed that the coating had provided an airtight sealing surface before autoclave testing began. A composite layup was placed on the tool over multiple autoclave cycles, during each of which the tool was methodically heated to 350°F for 120 – 135 minutes, with increasing levels (up to 85 ±5 psig) of autoclave pressure applied as the temperature rose above 225°F.

After the fifth cycle of these tests, a handheld 3D scanner revealed that 99.7% of the tooling surface was within ±0.004 inches of the baseline scan. Furthermore, results indicated that this small amount of movement occurred during the first five autoclave cycles, after which the tool stabilized and showed no additional movement during the subsequent 15 cycles. SABIC says that the study confirmed large-format additive manufacturing’s viability toward autoclave tooling — or at least tooling capable of withstanding 20 standard autoclave cycles without introducing dimensional inaccuracies into the part. In other words, perfect for low volume, complex tools.

Related Content

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

-

Sustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.