Design for additive manufacturing (DFAM) goes farther than design for manufacturing (DFM)—it’s more than just creating a part that can be 3D printed. AM technology enables better parts, if the designer can take advantage of its abilities at this stage.

Strategies such as topology optimization and generative design have emerged as natural companions to 3D printing, because they can create designs only AM can build.

I recently spoke with Eric Miller, cofounder and principal at Phoenix Analysis & Design Technologies (PADT) about the differences between generative design and topology optimization, how the strategies are being applied, and why the human touch still matters. Watch our conversation above or read on for the transcript.

(Want to learn how simulation can assist with DFAM and more? See another portion of our conversation dealing with AM and simulation here.)

Transcript

Stephanie Hendrixson, Additive Manufacturing

Design for additive manufacturing goes beyond simply creating parts that can be 3D printed. True DFAM takes advantage of additive’s unique benefits for things like customization, assembly consolidation and lightweighting.

There are simulation-based software tools that can help with this, but they’re all a little bit different and designed to do different things. At the same time, there’s also this very real human element to design that we can’t ignore. I recently sat down with Eric Miller, cofounder and principal of PADT, to talk about these issues and how to think about design within additive manufacturing.

We talk about generative design and we talk about topology optimization—and in your view, what is the difference between those two? How should we understand those two different things?

Eric Miller, Phoenix Analysis & Design Technologies (PADT)

So what topological optimization is saying is I've got these loads and I'm going to remove material in order to minimize the amount of material that I have. And it's actually a fairly simple process of putting a load on, looking where the stresses are, where there's no stresses, reduce the stiffness and the density, and keep doing that until you get holes and your part is going to work.

The big difference for me between generative and topological is generative gets into other ways of doing things. We're starting to see people explore growing the part.

So one of the best generative design things in the world is organic systems—plants. Or your bones, right? Your bones have density based upon where load is. And that grows. Material is not removed, it grows that way. So there's research going on in generative looking at how do we grow the part rather than remove material.

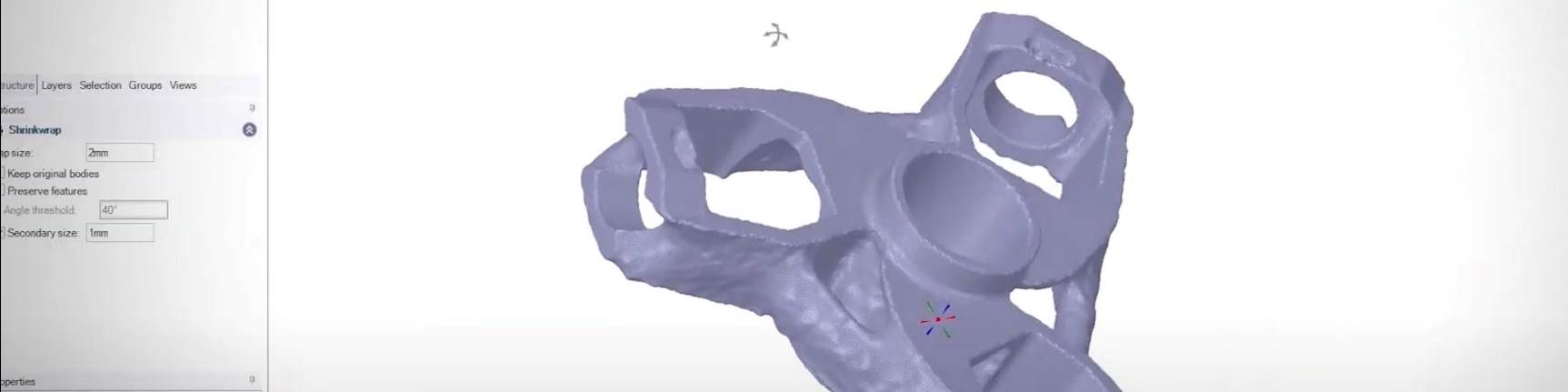

Another area is we like to put these kind of lattice structures inside things. So what about optimizing that lattice structure to meet the loads. So instead of removing material we're changing the shape and density and orientation of that lattice structure to get the optimal design.

So generative is really for me is about generating a design that meets the requirements and that includes the loads, it includes the cost, it includes manufacturing. Putting all those things in there and then doing iterative simulation to figure out what the optimal design is, is really what generative design is going to be in the future.

Stephanie Hendrixson

Can you think of an example where simulation saved time, effort, had some kind of benefit to an additive part?

Eric Miller

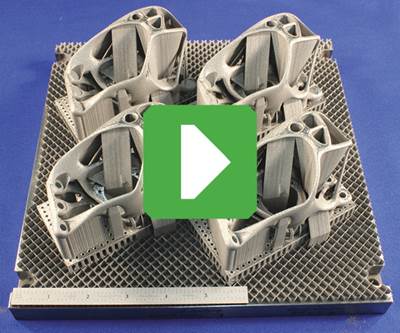

We have a couple of customers that are designing parts both in polymer and metal and I'll talk about the one of the polymer ones first. It's for a space application. It was a typical AM use case where they had a big assembly that was bolted and glued together, and they turned into one part that they did with AM but they had issues with rigidity and vibration and so they used simulation to go ahead and optimize that shape, to find out where they needed to add thickness where they could remove thickness; where they had to add ribs. They used that to really optimize the part and get a well-built part out of the process and that's on a polymer side.

On the metal side we're seeing our aerospace customers started adopting it, not just to optimize the designs. So it's becoming almost standard for them to use some topological optimization at least to guide them in their design. They may not go with the shape, but it kind of tells them which direction to go in, and then go ahead and verify the part which is part of their normal simulation process. And we're starting to see one or two really look at using it on the production side for figuring out how to get these parts out faster.

We found that we can do a part in one iteration. So we've got a little sample part that we do that's like a just a “T” shape, two cylinders that look like a T. And that's kind of our test part when we get any kind of a new machine. And we were able to use simulation to get that part with no faults right out of the machine right away.

Stephanie Hendrixson

You said something interesting in talking about your customers using topology optimization as a way of guiding their decisions, not wholesale following the recommendation. So what's the human component to this?

Eric Miller

I think someday we'll get there where we'll be able to use machine learning or something to look at a part and go "Oh, that's not going to work," but you know a lot of these design engineers have decades of experience and they've failed before. They built up that big data in their head, and they can look at a part and do pattern recognition and go, "If I don't put a rib there, I know that part's going to buckle.” That's something that because they didn't tell the computer to look for that, it didn't find it.

I think the other reason why is sometimes the parts just look too different. Is there an engineering reason not to do them? I don't know. It depends part to part. But will customers adopt something that funky looking? The left side and the right side maybe slightly different and the customer will look at that or the end user will look at that and go, “There's something wrong with that part. It's not made right.”

So we'll make the two sides symmetric even though optimally one side doesn't need as much material. So those are the kind of things that we look at. Aesthetics plays an important role.

Related Content

Variable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read MoreRead Next

Video: 3 Roles for Simulation in Additive Manufacturing

This conversation with PADT’s Eric Miller explores how simulation and 3D printing work together at three distinct stages in additive manufacturing, for DFAM and beyond.

Read MoreTopology Optimized 3D Printed Spine Implant: The Cool Parts Show #2

Medical contract manufacturer Tangible Solutions shares a titanium 3D printed spine implant with an unusual lattice structure in this episode of The Cool Parts Show.

Read MoreAdditive Manufacturing Is Changing How We Design

Geometric freedom is just the start. AM will also change how design happens.

Read More

.jpg;width=70;height=70;mode=crop)