Balancing lead time, cost and quality for mold tooling is a persistent dilemma injection molders face.

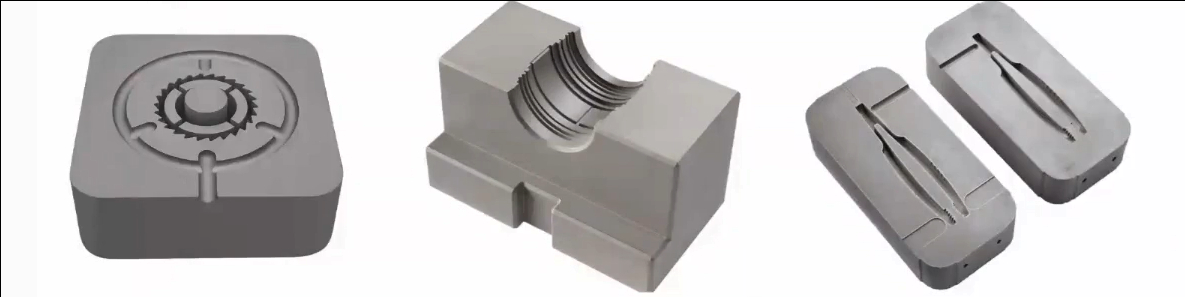

Mantle’s Trueshape Technology produces readily usable inserts at a faster pace than traditional mold making. Photo credit: Mantle

Nicolet Plastics LLC (Nicolet Plastics), a longstanding (circa 1985), custom plastic injection molding company faces this routinely. Servicing a diverse platform of clientele, Nicolet Plastics offers expertise in molding complex, high-quality parts with an array of engineered resins. The company’s first venture into additive manufacturing came in 2019, when it invested in a 3D printer for plastic parts production. Facing the ever-increasing challenge of equipping its injection molding process, it turned to AM for this as well, consulting AM company, Mantle, and its recent technology development for 3D printed mold tooling.

Mantle’s 3D printed mold solution combines metal deposition without melting with CNC machining to overcome previous limitations with metal 3D printers used for moldmaking. In a recent webinar, technical sales and application engineer of Nicolet Plastics, Eric Derner, along with Mantle director of technical marketing Ethan Rejto, discuss what the recent technology has to offer injection molders.

The Changing Landscape of Toolmaking

Mantle’s moldmaking process employs a hybrid additive/subtractive process. Known as Trueshape, Mantle’s technology combines CNC machining with 3D printing, employing metal in a paste-like form to generate dimensionally precise tooling pieces quickly and cost-effectively. The process, simply put? Print. Dry. Shape. Repeat layer by layer. Sinter after the entire tool is done.

Using Trueshape moldmaking technology, Nicolet Plastics has overcome leadtime challenges. “I think the biggest thing I see with Mantle is being able to produce production tooling in prototype time,” says Derner. He adds that the printed inserts are 75-95% complete, requiring minimal user interaction post-build before Mantle’s high-temperature furnace heats and thus solidifies the part being printed into a solid metal. “The process has saved companies [like Nicolet Plastics] lead time, shortening it from six to two weeks, as well as trimming operations time, going from 150 hours to 12 hours,” Rejto says.

Reducing the steps in creating a mold tool component to a single-step process brings further advantages. “It’s dramatically reducing tool time, but even more so, [reducing] operator mistakes. When you think about building tools [conventionally], there’s always the element of human error that can occur. With the Mantle solution, it’s just not as present anymore,” Derner says.

The time saved frees up Nicolet Plastics’ toolmakers for other critical projects, allowing more capacity for the company in terms of expanding business and services offered.

Nicolet Plastics’ Success With Mantle Technology

One of Nicolet Plastics’ clients, Gamber-Johnson, is a company that creates docking stations for devices such as laptops and cell phones. If a manufacturer invents a new handheld device, Gamber-Johnson might face the challenge of creating a compliant docking station. The company turned to Nicolet Plastics to reduce leadtime on a component for a slam latch — a piece intended for tablets that enable devices to easily connect to a docking station.

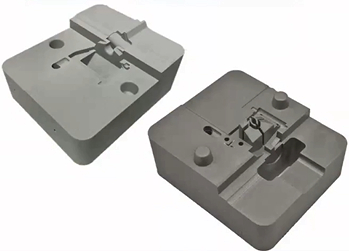

The Mantle tooling is depicted in gray while the resulting slam latch is pictured in blue. Photo credit: Mantle

Consisting of challenging geometry, the part had steeply angled faces and thin ribs, according to Derner. If traditionally fabricated, it could have taken up to six weeks to obtain the needed tooling and perform the molding. In comparison, Mantle’s Trueshape technology enabled Nicolet Plastics to access its first mold tool in about 10 hours. “Our lead time was reduced from six weeks to two,” shares Derner.

Additional Accomplishment

Another customer success story using Mantle technology comes from Tessy Plastics, a large-scale global contract manufacturer. In this case, the evaluation focused on the overall durability of Mantle’s tooling.

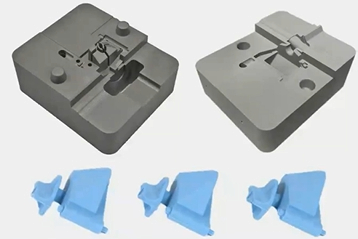

Tessy Plastics utilized Mantle’s moldmaking technology for its deodorant stick design. The tool is pictured in gray. Photo credit: Mantle

The tool in question was utilized for molding a deodorant stick thumb wheel, which propels the deodorant to the surface when turned or pushed upward. Tessy Plastics decided to evaluate how Mantle’s Trueshape technology compared to traditional mold tooling for the creation of this product.

The inserts Mantle technology printed have now run for over a year, producing over 1.65 million cycles (and counting) with no signs of wear and tear on the tooling. These inserts are being obtained weeks faster than conventional machined inserts, and according to Tessy Plastics, have comparable accuracy as well as durability thus far.

Related Content

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreRead Next

Mold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

Read MoreMantle Metal 3D Printing System for Toolmaking, Prototypes

The technology is designed for easy installation and use so that, with minimal training, manufacturers can have users quickly operating and running the machine.

Read MoreHow to Prepare for the Rise of AM in Moldmaking

Mold builders should consider investing in three key areas to take advantage of the opportunities 3D printing presents.

Read More