Mazak MegaStir Will Be Exclusive Tooling Supplier for Meld Solid Deposition Technology

Mazak MegaStir will provide its hard metal expertise along with tooling specifically developed for the Meld process that also incorporates the use of friction as part of its solid deposition process.

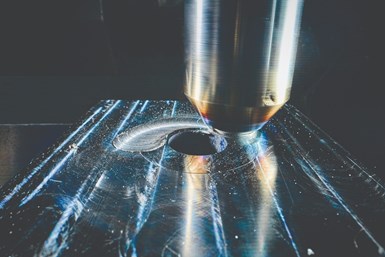

A rotating FSW tool plunges into the workpiece, dwells momentarily to enable rotation, friction and pressure to create a plasticized material pool, then traverses the workpiece to create the weld. Photo Credit: Mazak

Mazak MegaStir has signed an agreement making it the exclusive tooling supplier for Meld Manufacturing’s solid deposition technology. As a pioneer in friction stir welding (FSW) technology, Mazak MegaStir will provide its hard metal expertise along with tooling specifically developed for the Meld process that also incorporates the use of friction as part of its solid deposition process.

Mazak MegaStir has the ability to provide the complex tooling with the high-strength capability necessary to commercialize Meld’s solid deposition technology, according to Dale Fleck, general manager of Mazak MegaStir. The tooling is made from ultrahard materials (such as PCBN and carbide) and withstands the extremely high loads and forces necessary for the process.

Like Mazak MegaStir’s FSW process, solid deposition is also a solid way of joining, but as part of an additive process for the joining of stacked material layers to produce/build structures. As these layers are deposited, the Mazak MegaStir tooling — operating with applied pressure and frictional load — spins and joins the layers together. The tooling mounts into deposition heads on CNC machine platforms with the ability to feed the metal material down through the center of the head and the tooling.

Meld Manufacturing is based in Christianburg, Virginia, and its Meld process is capable of printing large metal parts at a scale not yet achieved in the metal additive market, the company says. As a solid-state process, it can produce high-quality materials and parts with low residual stresses and full density with significantly lower energy requirements than more conventional fusion-based processes.

Because the Meld process occurs in the solid state, it also produces materials that are not susceptible to porosity, hot cracking or other common problems that plague melt-based technologies. Meld is a single-step process that does not require time-consuming follow-on processes such as hot isostatic pressing (HIP) or sintering to improve the quality of the deposited material.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

-

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

In a recent case study, Alpine Advanced Materials partnered with Nexa3D to produce 3D printed tooling for injection molded composites. Utilizing Nexa3D’s XiP desktop 3D printer and its Freeform Injection Molding process, Alpine was able to reduce prototype tooling production time and cost alike for its customers.